The Ultimate Guide to CNC Milling Services

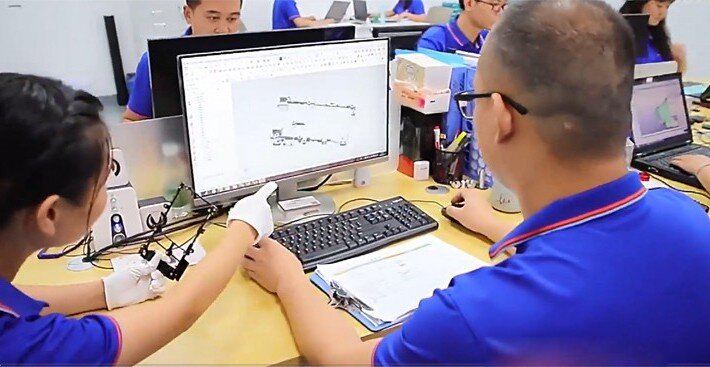

CNC milling services is a machining process that uses computer control and rotating multi-point cutting tools to progressively remove material from a workpiece and produce a custom-designed part or product. The process is suitable for machining a variety of materials, such as metals, plastics, wood, and producing a variety of custom-designed parts and products.What is