This article contains everything you need to know about CNC machining steel and various considerations for getting the best results. Steel is one of the most widely used metals in the world today. Steel is an iron alloy in which additions of carbon and other elements determine the specific alloy of the steel and its properties. The carbon content is about 1%-2%, and other alloying elements include manganese, silicon, phosphorus, sulfur and oxygen. For example, carbon increases the hardness and strength of steel; manganese is usually present in order to reduce the brittleness of steel and increase its strength.

Table of Contents

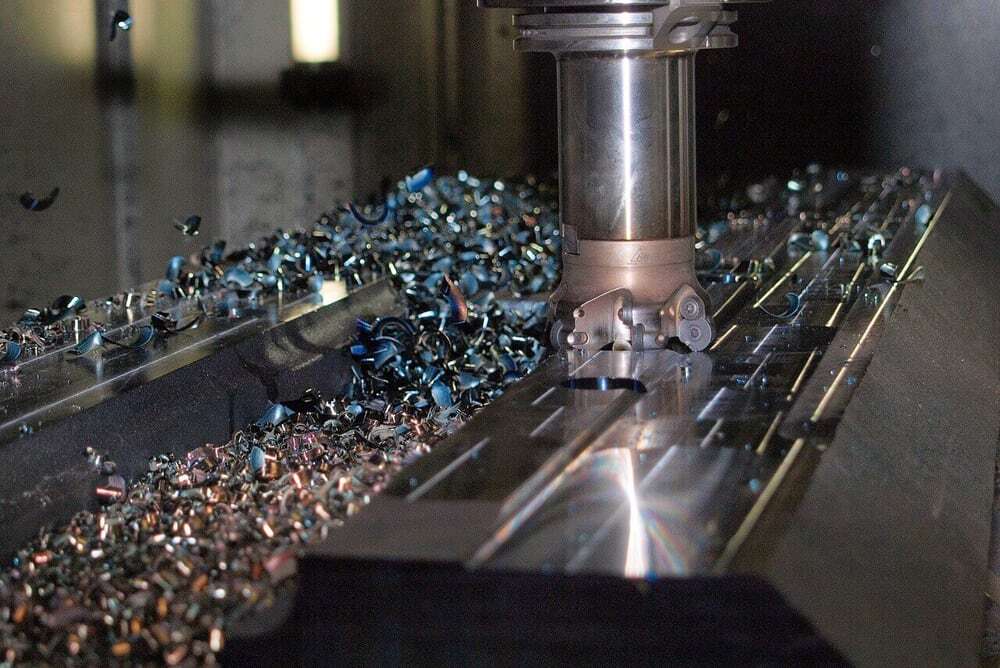

ToggleSteel is one of the preferred materials for CNC machining

Steel and aluminum are often the materials of choice for many applications in industries such as automotive, aerospace and robotics that require high performance, durable parts. However, steel and aluminum have completely different physical properties and costs, so it is important to determine which material is better for custom parts. One of these determining factors is often the method of manufacture, and the process of choice for custom metal parts is usually CNC machining. When CNC machining metal parts, there are a few key reasons why steel may be a more suitable material choice than aluminum. While aluminum is very light, steel is stronger. What’s more, aluminum can be more expensive than steel. Steel is easy to machine and weld, thus providing a good balance between cost and functionality. However, steel is not without its drawbacks. Steel oxidizes over time and requires surface treatments for protection. Therefore, it is important to carefully evaluate the different steels and their respective advantages and limitations during the material selection process. The Rapid Manufacturing team should have knowledge of each steel to choose the best type of steel for the client’s CNC project.

CNC Machining Steel Types

As you may already be aware, CNC machining steel parts is a very versatile method. However, you may be wondering which type of steel is best for your project and how to tell if you’ve chosen the right one. The properties of CNC machined steel parts that you must consider along with our top 10 steel types for CNC machining in order to provide an excellent choice for your next CNC project for the best results. AN-Prototype summarizes the characteristics of various steel materials based on years of experience in CNC machining steel.

4140 steel

4140 steel is a low alloy steel that contains low levels of chromium, molybdenum and manganese. These alloying elements increase the strength, ductility and toughness of the steel grade. Additionally, the added chromium content makes 4140 steel more resistant to corrosion. Therefore, 4140 steel is used in many industries due to its good machinability and wear resistance. However, 4140 steel is not the easiest to weld and may require pre- and post-heat treatments. 4140 steel is often found in CNC steel parts used in couplings, spindles, bolts, nuts and automotive parts.

4140 steel Mechanical properties

- Yield tensile strength (MPa): 655

- Shear modulus (GPa): 80

- Elongation at break (%): 19

- Hardness (Brinell): 197

- Density (g cm-3): 7.87

Steel 4140 PH

Steel 4140 PH is a pre-hardened version of standard 4140 steel with excellent mechanical strength and hardness properties. Its pre-hardening eliminates the need for heat treatment after CNC machining. Steel 4140 PH is ideal if heat treatment would cause unacceptable deformation of the finished part. Typical applications include shafts, mandrels and dies.

4140 PH Steel Mechanical Properties

- Tensile Strength:1241

- Shear Modulus (GPa):80

- Elongation at Break (%):14

- Hardness (Brinell):429

- Density (g/cm^3):7.8

4130 steel

Compared with other steels, 4130 steel has more alloy elements, including iron, carbon, chromium, manganese, molybdenum, phosphorus, silicon and sulfur. These alloying elements determine the toughness, CNC machinability and thermal compatibility of 4130 steel. Due to its ability to withstand high stresses, 4130 steel is commonly used in various construction industries. In addition, 4130 steel is also used in aircraft engine brackets. Fast builders often prefer 4130 steel over aerospace grade steel because it is less expensive and just as effective.

Although easy to heat treat, 4130 steel is not easy to weld.

4130 steel mechanical properties

- Yield tensile strength (MPa): 460

- Shear modulus (GPa): 80

- Elongation at break (%): 20

- Hardness (Brinell): 217

- Density (g cm-3): 7.87

1018 steel

1018 steel is generally considered a low carbon steel, and its alloying elements include iron, carbon, manganese, phosphorus and sulfur. The biggest advantage of CNC machining 1018 steel is its high weldability, making it the default choice for carburizing CNC steel parts. Note, however, that welding is only recommended after carburizing. In addition to being very easy to weld, 1018 steel also has excellent machinability. This is the basis for its use in CNC precision machining processes such as steel CNC turning and CNC milling. In general, 1018 steel is often applied to tie rods, mandrels, shafts, and many other mold components.

The main disadvantage of 1018 steel is that it is incompatible with many finishing processes and relatively expensive.

1018 steel mechanical properties

- Yield tensile strength (MPa): 310

- Shear modulus (GPa): 78

- Elongation at break (%): 15

- Hardness (Brinell): 131

- Density (g cm-3): 7.87

1045 steel

1045 steel is a medium carbon steel whose alloying elements are iron, carbon, silicon, manganese, sulfur or phosphorus. 1045 steel is one of the most versatile steel grades used by rapid manufacturers for machining CNC steel parts. 1045 steel is strong and tough, justifying its use in many CNC steel machining projects where water resistance is critical. Additionally, 1045 steel is machinable and weldable, both important considerations for manufacturers when machining steel. Applications for 1045 steel include bolts, gears, shafts and studs. Although 1045 steel is relatively strong, it is not recommended for very strong applications due to its only moderate tensile strength and hardenability.

1045 steel mechanical properties

- Yield tensile strength (MPa): 450

- Shear modulus (GPa): 60

- Elongation at break (%): 12

- Hardness (Brinell): 170

- Density (g cm-3): 7.87

1215 steel

The alloying elements of 1215 steel contain iron, carbon, manganese, phosphorus and sulfur. Due to its relatively high sulfur content, 1215 steel is considered an easy CNC cutting steel. 1215 steel forms small chips during CNC machining, allowing for higher machining rates and avoiding tangling in the machine. However, 1215 steel is not very weldable. Also, due to its relatively low carbon content, it is not as strong as other steel grades. In industry, 1215 steel is suitable for the manufacture of studs, pins, screws, couplings and hose fittings.

1215 steel mechanical properties

- Yield tensile strength (MPa): 415

- Shear modulus (GPa): 80

- Elongation at break (%): 10

- Hardness (Brinell): 167

- Density (g cm-3): 7.87

A36 steel

A36 steel is cheap and easy to weld, so it is a very common mild steel. A36 steel is commonly used to manufacture parts applied to structural support.

A36 steel properties

- Tensile Strength:250

- Shear Modulus (GPa):79.3

- Elongation at Break (%):20

- Hardness (Brinell):119

- Density (g/cm^3):7.85

A2 tool steel

A2 tool steel is an air-hardening cold-work steel with good wear resistance and minimal deformation during heat treatment or hardening. Compared to other types of tool steels, A2 steels are relatively easy to CNC machine. A2 tool steel is one of the most commonly used steel grades for making tools such as punches, trimming and forming dies, shearing blades and dies.

A2 tool steel mechanical properties

- Tensile Strength:415

- Shear Modulus (GPa):78

- Elongation at Break (%):21

- Hardness:57-62 HRC

- Density (g/cm^3):7.86

O1 tool steel

O1 steel is an oil hardened cold worked steel. It is characterized by strong abrasion resistance and the ability to retain sharp edges. O1 tool steels are commonly used in the manufacture of punching, cutting and stamping tools, as well as blades and other cutting tools.

O1 tool steel mechanical properties

- Tensile Strength:400

- Shear Modulus (GPa):77

- Elongation at Break (%):20

- Hardness:63-65 HRC

- Density (g/cm^3):7.83

Advantages and Challenges of CNC Machining Steel Parts

CNC machining steel parts requires a lot of experience and skill to achieve reliable results every time. The benefits gained from using steel parts often outweigh the challenges of CNC machining.

Benefits of CNC Machining Steel

Most CNC machined steel parts today are well machinable, i.e. can be easily cut or formed to give good results. Factors such as hardness, energy, and shear stress can affect the machinability of steel CNC machining. Another benefit of CNC machining machine parts from steel is that the products are highly resistant to corrosion and wear. Additionally, CNC machining steel parts are often compatible with many surface finishes.

Challenges of CNC Machining Steel

Despite the many benefits of steel parts, there are still some challenges when CNC machining steel parts. For one, not all steel parts are easy to CNC machine. Therefore, this means that it may be difficult to use certain steel grades for CNC projects with complex geometries. In addition, different steel grades have different heat sensitivities. Some grades of steel are not suitable for CNC steel parts that are subjected to a lot of heat because they may melt and deform.

Steel Treatment

Some of steel’s most useful properties come from additional handling and machining. These methods can be done prior to CNC machining to alter properties and make the steel easier to machine. Keep in mind that hardening the material prior to CNC machining increases machining times and increases the chances of tool wear. Steel can also be treated after CNC machining to increase the strength or hardness of the finished product. That said, it’s important to think upfront about any planned treatments you need to apply to achieve the necessary properties for steel part treatments.

Heat Treatment

Heat treatment refers to several different processes that involve controlling the temperature of steel to alter its material properties. An example is annealing, which is used to reduce the hardness of steel and increase ductility, making the steel easier to CNC machine. The annealing process slowly heats the steel to the desired temperature and holds it there for a period of time. The time and temperature required depend on the specific steel alloy and decrease with increasing carbon content. Finally, the metal is slowly cooled in a furnace or surrounded by insulation.

Normalizing heat treatment relieves internal stress in steel while maintaining higher strength and hardness than annealed steel. During normalizing, the steel is heated to a high temperature and then air cooled to achieve higher hardness.

Hardening steel is another heat treatment process that hardens the steel and also increases strength, but also makes the material more brittle. The hardening process involves slowly heating the steel, soaking it at high temperatures, and then rapidly cooling it by immersing it in a liquid such as water, oil or a brine solution.

Tempering heat treatment process to alleviate some of the brittleness produced by hardened steel. Tempering of steel is almost identical to normalizing: slowly heating to a selected temperature, then air cooling the steel. The difference is that the tempering temperature is lower than other processes, which reduces the brittleness and hardness of the tempered steel.

Precipitation Hardening

Precipitation hardening increases the yield strength of steel. Some grades of stainless steel may contain PH in their designation, which means they have precipitation hardening properties. The main difference between precipitation hardening steels is that they contain additional elements: copper, aluminum, phosphorus or titanium, etc. To activate the precipitation hardening properties, the steel is formed into its final shape and then undergoes an age hardening process. The age hardening process heats the material for an extended period of time, causing the added elements to precipitate, forming solid particles of different sizes, which increases the strength of the material.

17-4PH (also known as 630 steel) is a common example of a precipitation hardening stainless steel. The alloy contains 17% chromium, 4% nickel, and 4% copper to aid in precipitation hardening. Due to increased hardness, strength and high corrosion resistance.

Cold Working

The properties of steel can also be changed without applying large amounts of heat. For example, cold worked steels are made stronger through a process of work hardening. Work hardening occurs when metals undergo plastic deformation. This can be done intentionally by hammering, rolling or drawing the metal. Work hardening can also occur unintentionally during machining if the cutting tool or workpiece becomes too hot. Cold working also improves the CNC machinability of the steel. Mild steel is very suitable for cold working.

Surface Finishing Options for CNC Machining Steel Parts

Surface treatment is the surface treatment process of steel parts after CNC machining, and its purpose is to improve the function and aesthetics of steel parts. For steel parts, the following are common surface treatments that apply.

Nickel Plating: Carbon steel parts can be uniformly plated with nickel to improve their corrosion and wear resistance. The process deposits a 0.1 mm thick layer of nickel on the surface of the part.

Powder Coat: Powder Coat creates a strong surface finish and is typically between 0.006″ (0.1524mm) and 0.012″ (0.3048mm) thick. Since steel parts are prone to rust, powder coating can retard rust.

Carburizing: Some steels can be significantly improved by carburizing, which is the injection of additional carbon into the surface, increasing the hardness and wear resistance of steel parts.

Grinding:Precision grinding helps steel parts have a smoother surface and eliminate irregularities. Speedmakers use grinding wheels to do this.

AN-Prototype's CNC Machining Steel Services

CNC steel parts are common in many industries today. Before CNC machining a steel, a rapid manufacturer must determine the best grade of steel. This involves evaluating various steel grade properties against the needs of the CNC project. When all factors are considered, quality CNC machining services are of the utmost importance.

At AN-Prototype, we have dedicated CNC machining steel specialists who can handle all of your steel CNC machining services. We can guarantee the precision, quality and economy of your project components. Specifically, we handle CNC steel milling, turning, grinding, EDM and wire EDM. Upload your CAD file now for one-on-one support and hear back within 12 hours.