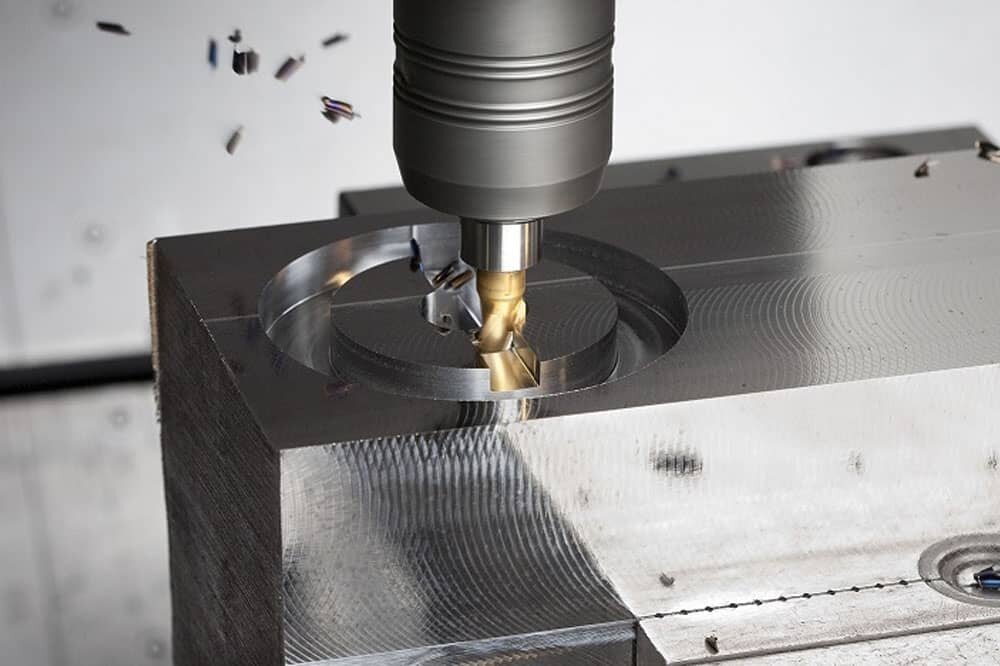

Today’s CNC machining market is diverse. However, when processing materials, we still need to consider the problem of time, cost and use. Titanium and stainless steel are our commonly used materials, in the processing of such materials should also consider its strength, weight, whether it has corrosion resistance, heat resistance and whether it is suitable for this field of work and so on. The purpose of this blog is to introduce the difference between titanium and stainless steel, uses, advantages and disadvantages, processing methods and other information. Provide constructive advice for you to choose the right material processing.

Table of Contents

ToggleTitanium vs Stainless Steel, What is the Difference?

Every industry is looking for innovative ways to bring products to market in very little time. When lower cost materials are selected, profits will be maximized. Titanium and stainless steel are two metals, some people are very familiar with these two metals, but many people do not know what the difference is between titanium alloy and stainless steel alloy, in fact, the difference between the two is very big, through the appearance can be distinguished, the price of the two is not the same.

Titanium is a strong, lightweight material that has many different uses. Because of the price, titanium and stainless steel are often used to compare. The main difference between stainless steel and titanium is that stainless steel is an alloy metal, while titanium is a metal. The unique properties of stainless steel are created by adding alloy metals made of iron, chromium and other metals. One of the biggest advantages of stainless steel is that it can be recycled, which is very beneficial for us to protect the environment. At the same time, there is a film on the surface of stainless steel, which can prevent rust and extend the service life. If you compare two metals of the same size, the weight of stainless steel will be nearly 55% heavier than titanium. The cost of titanium of the same size is six times that of stainless steel. The metal of both materials is very strong, of course, factors will affect the final choice, need to consider the cost and the characteristics of the metal. A simple comparison of the properties of these metals will reveal how they differ and exactly what kind of material is suitable for that field.

Titanium and Stainless Steel have different densities:

Titanium is a silver-white transition metal with the chemical symbol Ti and atomic number 22. With a glossy silver appearance and a melting point of 1,668°C (3,034°F), it is not only excellent heat resistance but also known for its excellent strength and corrosion resistance. At the same time, titanium is highly biocompatible and suitable for medical implants and surgical instruments. Such as pacemakers, skull plates, and even root devices used as dental implants. Titanium has a relatively low density of about 4.5 grams per cubic centimeter (g/cm³).

The color of stainless steel is divided into titanium, titanium black, sapphire blue, bronze, rose gold, champagne gold and other density. Depending on the synthetic material, the density of stainless steel will also be different, about 7.70-8.00 (g/cm³) range. From the chemical composition analysis: chromium stainless steel density 7.75 (g/cm³), chromium nickel stainless steel density: (g/cm³). Common stainless steels such as 304/316 are chrome-nickel stainless steels. Different models of stainless steel melting point is different: 201 stainless steel is 650 degrees Celsius, 304 stainless steel is 1400 degrees Celsius, 314 stainless steel is 920 degrees Celsius, 316 stainless steel is 1100 degrees Celsius, 2520 stainless steel is 1450 degrees Celsius. (Stainless Steel) is the abbreviation of stainless acid-resistant steel, resistant to air, steam, water and other weak corrosive media or stainless steel; The steel that is resistant to chemical corrosion media (acid, alkali, salt and other chemical etching) is called acid-resistant steel.

Titanium and Stainless Steel differ in weight

The density of titanium is 4.51 g/cm3, and the density of stainless steel is 7.70-7.90 g/cm3. Titanium is much lighter than stainless steel, making it ideal for applications where weight is a major consideration. In addition, titanium has a higher strength-to-weight ratio than stainless steel, which means it can support more weight while still being light. Titanium and stainless steel are excellent materials, they each have advantages and disadvantages, suitable for different applications. If there are high requirements for the weight of the product, you can choose to use titanium alloy. If there are higher requirements for corrosion resistance and strength, stainless steel is a better choice.

Titanium and Stainless Steel have different uses

Titanium because of its durability, high strength and light weight. Titanium can be used in aerospace industry, daily necessities, medical field, sports and entertainment, Marine applications.

Aerospace industry: Titanium can be produced spray paint engine body parts, satellites, rockets, missiles and other parts. Titanium is commonly used in aircraft: fuselage, engine components and landing gear to help improve fuel efficiency and performance.

Medical field: Titanium implants, including bone plates, dental implants and artificial joints, prosthetics, use their biocompatibility and lightweight properties to promote faster healing.

Sports and entertainment: Spectacle frames, watches, crutches, fishing rods, kitchenware, digital products, handicrafts, golf heads, golf clubs, tennis rackets, badminton rackets, ski poles and skate blades, decorations, etc. Titanium can also be used in sports equipment such as bicycle frames, golf and tennis rackets, increasing flexibility and operability without compromising durability.

Marine applications: The corrosion resistance and low density of titanium can be applied to seawater desalination pipelines, offshore oil drilling pumps, valves, pipe fittings, and Marine components such as propeller shafts and offshore structures, where weight reduction is critical for efficiency and longevity.

Stainless steel is a very versatile material that can be used in a variety of industries. Fields of stainless steel: kitchenware, automotive, medical, construction, industrial chemicals, aerospace.

Kitchenware: Stainless steel is resistant to staining, rust and corrosion, making it an ideal material for cookware, tableware and kitchen utensils.

Food packaging: Stainless steel is the first choice for food processing equipment and storage tanks and lunch boxes because it is easy to keep clean and does not corrode.

Automotive: Stainless steel is used in exhaust systems, radiators and other automotive components. Due to its strength and corrosion resistance, it is not easy to rust and is reliable.

Medical: Doctors rely on surgical instruments, implants and medical devices made of stainless steel because it is safe for the body and does not attract bacteria.

Construction construction: Stainless steel is often found in exterior walls and decorative structures because it has a long service life and can withstand harsh conditions.

Industrial chemicals: Stainless steel is widely used in pipes, automotive parts.

Aerospace: Stainless steel is used to make aircraft components, such as exhaust systems, that are not only strong but can also withstand high temperatures.

Overall, stainless steel is an excellent choice for many demanding applications because it is tough, corrosion-resistant, and can be used for many different purposes.

Titanium and Stainless Steel different prices

Titanium is more expensive than stainless steel. Due to its superior performance, although the cost of titanium is higher, it can make the value of the product leap. Using lightweight metal parts in aircraft or spacecraft can save a lot of fuel, and titanium parts also have a longer service life. Titanium is often used in high-end products. Titanium is often more expensive than stainless steel because of its rarity, the difficulty of extracting and refining it, and the high demand for the material in critical applications. Titanium is an elusive metal found only in certain parts of the globe; As a result, extracting and refining titanium requires specialized equipment and high-temperature processes as well as special alloys – which further increases costs.

Stainless steel is the most cost-effective metal for CNC machining or 3D printing, while it is also suitable for many other prototyping methods. For example: making molds. Production cost is the primary consideration in choosing for processing purposes, and stainless steel is generally cheaper to produce and cast than titanium.

In short, titanium is characterized by very high mining and manufacturing costs. When selecting materials, several factors need to be considered, such as cost, strength, durability and application requirements. Both titanium and stainless steel have unique advantages and challenges; It comes down to the material that best meets the needs of the project. In making this decision, material characteristics, manufacturing processes and production volumes must be considered. By carefully considering these details, An-prototype can make informed decisions and achieve the best results for your project.

Advantages of Titanium

1, High strength: the density of pure titanium is close to the density of ordinary steel, and some high-strength titanium alloys exceed the strength of many alloy structural steel.

2, High thermal strength: stainless steel can accept the processing temperature is several hundred degrees higher than its own, at a moderate temperature can still maintain the required strength, can work at a temperature of 450 ~ 500℃ for a long time. The strength of stainless steel alloy decreases significantly at 150℃.

3.Good low temperature performance: titanium alloy can still maintain its mechanical properties at low and ultra-low temperatures.

4,Good corrosion resistance:Titanium alloy works in humid atmosphere and seawater medium, its corrosion resistance is much better than stainless steel; Resistance to pitting corrosion, acid corrosion, stress corrosion is particularly strong; Excellent corrosion resistance to alkali, chloride, chlorine, nitric acid, sulfuric acid, etc. It should be noted that titanium has poor corrosion resistance to reducing oxygen and chromium salt media.

5, Chemical activity: Titanium has a large chemical activity and produces a strong chemical reaction with O, N, H, CO, CO2, water vapor, ammonia and so on in the atmosphere. When the carbon content is greater than 0.2%, hard Tic will be formed in titanium alloy. When the temperature is very high, TiN hard surface will be formed by the interaction with N; Above 600℃, titanium absorbs oxygen to form a hardened layer with high hardness; The embrittlement layer is also formed when the hydrogen content increases. The depth of the hard and brittle surface produced by the absorption of gas can reach 0.1 ~ 0.15mm, and the hardening degree is 20% ~ 30%. At the same time, the chemical affinity of titanium is also large, and it is easy to adhere to the friction surface.

Disadvantages of Titanium

1、The main limitation of titanium and titanium alloys is their poor chemical reactivity with other materials at high temperatures.

2、Titanium and the general traditional refining, melting and casting processing technology is different, because of its hardness often cause mold damage.

3, the price of titanium has become very expensive, so it is mostly used in aircraft structures, aircraft, and used in high-tech industries such as petroleum and chemical industries.

Advantages of Stainless Steel

1..Good processing performance: stainless steel is easy to process, shape and weld, suitable for a variety of complex shape processing needs.

2. Good high temperature strength: stainless steel can still maintain good strength and rigidity at high temperature, has good heat resistance, suitable for high temperature environment.

3. Strong corrosion resistance: stainless steel has ultra-high corrosion resistance, which can resist the erosion of common salt, acid, alkali and other corrosive media, and is used in special industrial environments.

4. Good wear resistance: stainless steel has very good wear resistance, can resist wear and maintain the beautiful finish of the surface.

5. Good comprehensive mechanical properties, high strength and fatigue strength, bending strength is about 2.1 times of 18-8 type austenitic stainless steel.

Disadvantage of Stainless Steel

Every metal substance has its disadvantages, and stainless steel is no exception. The main disadvantages also include the high cost, especially when testing the first batch of samples.When stainless steel is not processed using advanced processing machines and expertise, it can be a difficult metal to process. This often leads to costly waste and rework. Welding and heat treatment are unfavorable due to its rapid heat dissipation. This can also create broken pieces or high scrap costs, which will lead to high costs for final polishing and finishing. Although its durability is high, stainless steel rings can also sag. Compared to precious metals, only silver indentations are more common than stainless steel. Determining the size of stainless steel rings can be difficult because the metal is hard.

In addition, stainless steel may contain nickel, which can cause physical discomfort if you have a nickel allergy. The severity of allergies varies from person to person, so it is still recommended to be careful when purchasing stainless steel, and if you have a nickel allergy, you need to pay extra attention!

It is worth mentioning that with the development of science and technology, our materials are also diverse. If you are still worried about the suitability and cost of materials, of course, you can choose AN-prototype, AN-prototype has more than 15 years of CNC machining experience, can choose the right material for you to process, so as to reduce your production costs. The products produced have excellent quality, so that you have no worries.