Precision surface grinding is a subtractive manufacturing process that uses high-precision grinders to create parts with smooth surface textures. Precision grinders utilize a rotating grinding wheel coated with rough particles to flatten or smooth surfaces by removing chips from non-metallic or metallic materials. Along the way, the process precisely grinds the surface to give the part a more refined look. Precision grinding creates a finish that is both practical and attractive, making it a reliable technology for a wide range of applications.

Table of Contents

ToggleWhat is precision grinding?

Precision grinding involves using a precision grinder to remove material from a workpiece. This precision grinder uses an abrasive grinding wheel driven by an electric motor. With speeds ranging from 150 to 15,000 rpm, depending on the project, these motors make shallow cuts to produce fine finishes, shapes, and dimensions. Precision grinding is a practical solution for achieving tight tolerances and precise dimensions in the manufacturing process. The process is also compatible with a variety of materials including metals, ceramics, and minerals. If you want a process that can produce parts to specified dimensions (using the materials mentioned above), then precision grinding is ideal for you. For example, high-precision grinders can achieve diameter tolerances from +/- 13 microns to +/- 1.3 microns and roundness tolerances from +/- 2.5 to 0.25 microns. Likewise, precision grinding can also achieve precision in surface treatments with tolerances ranging from 0.20 to 0.81 microns.

Benefits of Precision Grinding

Precision grinding has become an important manufacturing technology in the manufacturing industry due to its advantages. AN-Prototype lists the benefits of precision grinding:

Cost-effectiveness and accuracy

Various industries require that parts must be manufactured according to the designed dimensions without any tolerance. In a certain sense, precision grinding is a processing technology that can meet this level of detail, ensuring the accuracy of parts while providing a cost-effective method of manufacturing different parts. Most metal fabricators use precision grinding processes to create complex parts with specific measurements within acceptable tolerances. In addition to this, grinding operations help improve the manufacturing productivity of precise parts while making it easier to control the consistency of part quality. All in all, precision grinding is an efficient manufacturing process.

Reliable Manufacturing Alternatives

Professional machinists use precision grinding processes when other manufacturing processes such as CNC milling and CNC turning are not available. This usually occurs for the following reasons:

- Material type

- High degree of surface finish quality

- Parts need to be manufactured with small diameters and tight tolerances.

Types of precision grinding technology

There are many types of precision grinding processes used to achieve precise surface finishes and dimensions of parts across a variety of industries. The characteristics of different types of precision grinding determine their respective applications in specific machining projects. Therefore, it is critical that manufacturers select the appropriate precision grinding operation based on the part’s size, shape, finishing characteristics and required productivity to achieve optimal results. Here are some of the most common types of precision grinding.

Centerless grinding

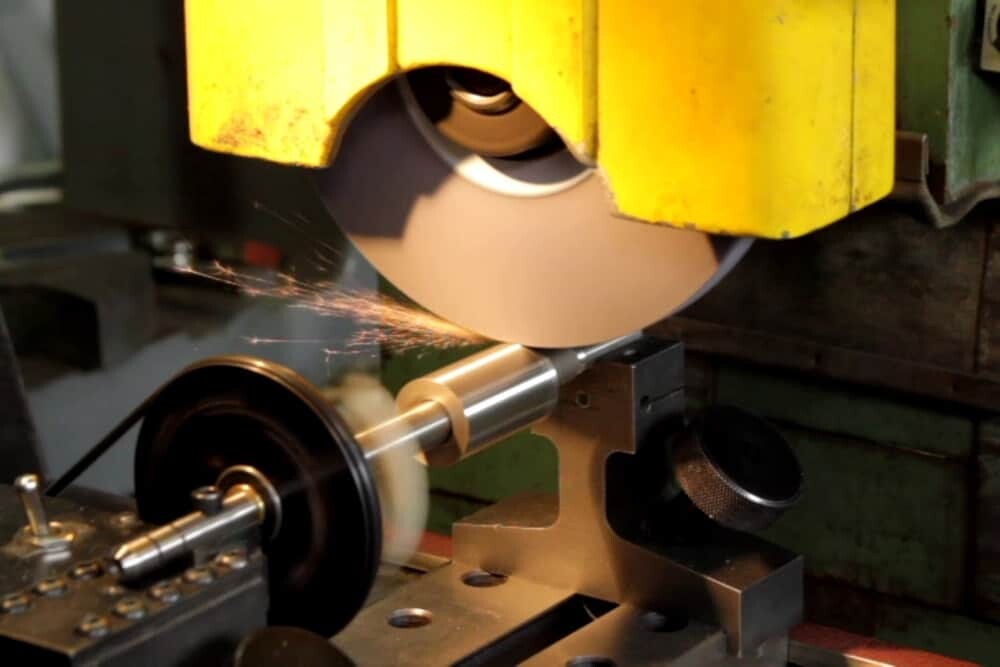

Centerless grinding is suitable for manufacturing long and slender parts. This process removes minute amounts of material from the outer diameter or perimeter of small cylindrical parts to achieve a specific surface finish. In most cases, rapid manufacturers use centerless grinding to enhance the surface finish of CNC-turned parts to achieve greater accuracy. In contrast to traditional outside diameter grinding operations, centerless grinding does not hold the workpiece in a center or between chucks. In contrast, centerless grinders use a stationary blade to support the workpiece on the outside diameter.

In addition, centerless grinding uses two wheels acting simultaneously: an abrasive grinding wheel and an adjusting wheel. Even if the two grinding wheels rotate in the same direction, the rotation speed of the grinding wheel is higher than the rotation speed of the adjustment wheel. This enables centerless grinding operations to grind very small parts. The two grinding wheels move at different speeds, with an abrasive precision grinder moving faster than an adjustment grinder.

Unlike other grinding processes, the workpiece moves in a centerless grinder without the need for fixtures or motors.

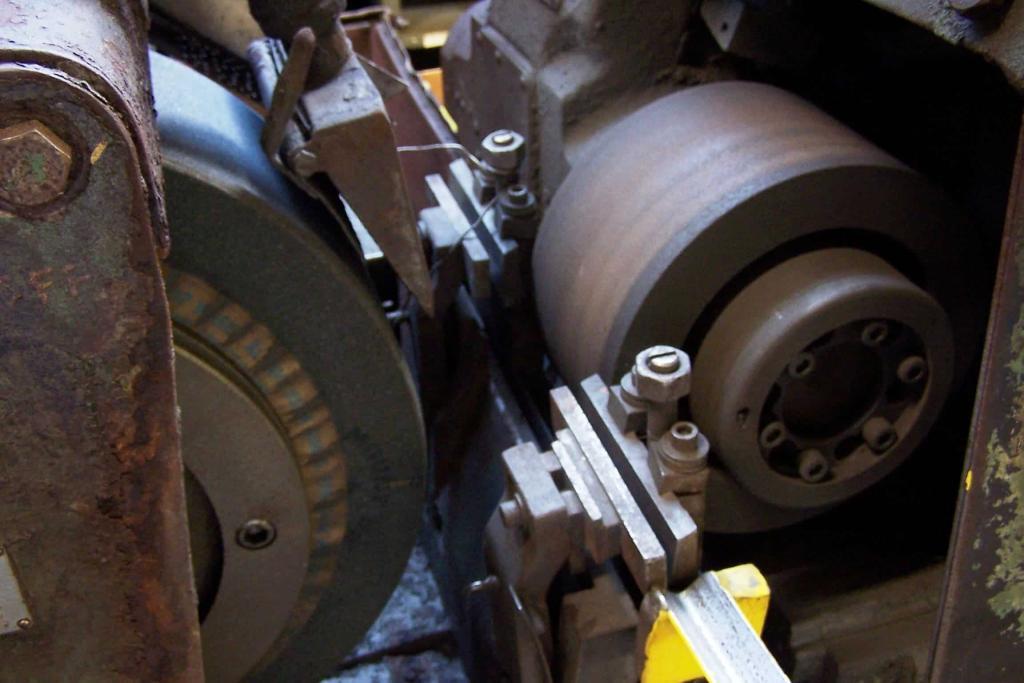

Single and double disc grinding

As the names suggest, single disc grinding and double disc grinding use single discs and double discs. With a single-disc precision grinder, the spindle typically holds the grinding disc vertically, while the chuck clamps the workpiece into position. Twin disc grinders are available in both vertical and horizontal versions, both of which can be used for a variety of precision grinding applications.

Cylindrical grinding

Cylindrical grinding is also called center grinding. The grinding machine used in this process includes a precision grinding wheel, two centers for holding the workpiece, a chuck for driving the workpiece, and a few other features. The rotation directions of the grinding disc and the workpiece are different, so chip removal is easy. There are two types of cylindrical grinding, including:

Internal diameter grinding

ID grinding technology removes excess material from the inside diameter of a hole, tube, or drilled hole. In this process, the center holds the workpiece at a fixed point and the chuck rotates the workpiece to reduce its diameter.

Outside diameter grinding

The function of outer diameter grinding is to grind the outer surface of the workpiece. The center holds the workpiece in place while the chuck rotates the workpiece in the same direction as the grinding disc for fine grinding. It is worth mentioning that for any of these techniques to be suitable for grinding, the part must be cylindrical.

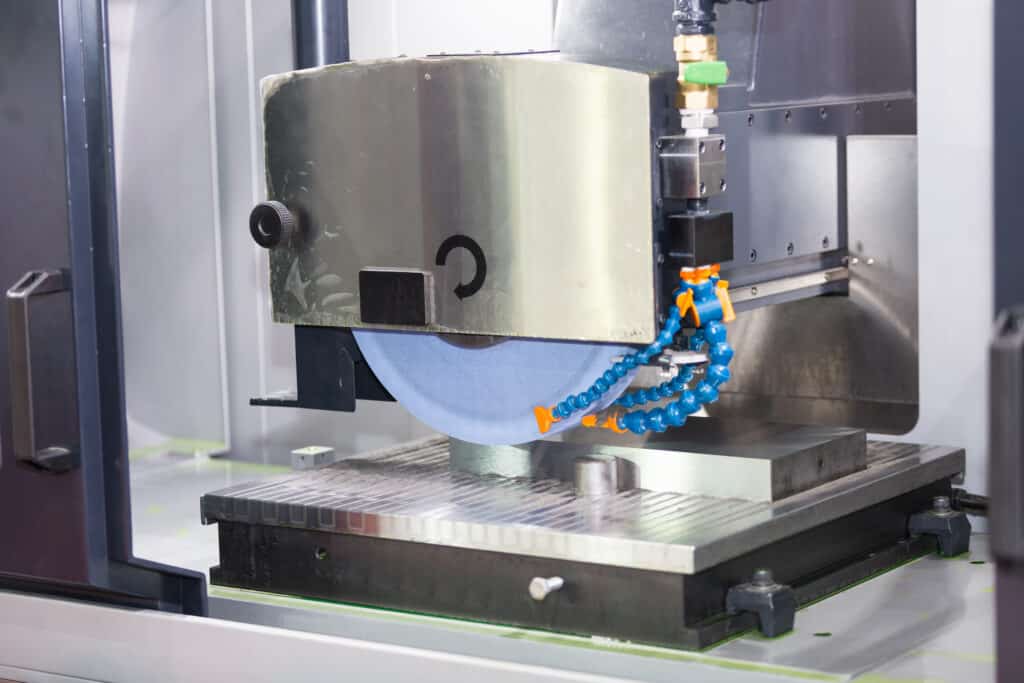

Surface Grinding

Precision surface grinding is a technique used to finish flat surfaces to produce a smooth surface, give a part a more refined appearance, or add specific functionality. It involves using a rotating wheel coated with rough abrasive grains to remove tiny chips or excess material from the surface of a workpiece. In addition to the grinding wheel, a surface grinder includes a chuck and a table that uses magnets to hold the material in place. When CNC turning and milling processes are not precise enough to manufacture a specific part, rapid manufacturers turn to precision surface grinding processes as an excellent alternative. This is because grinding operations can achieve micron-level tolerances and achieve finishes as low as 0.2 microns. It is important to note that the quality of surface finish obtained from surface grinding depends on factors such as wheel speed, feed rate, wheel size, abrasive, and material type.

Additionally, surface grinding is ideal for materials where the magnetic suction cup easily grips the material without clogging the grinding wheel. These materials include cast iron and many steel grades. Other materials such as aluminum, brass, and plastic can clog the grinding wheel, making it impossible to cut. Thus, only professional machinists can perform surface grinding operations on these materials.

Precision grinding applications

Due to the excellent performance of precision grinding, its applications span many industries that require careful manufacturing of high-quality parts, including aerospace, automotive, medical and electronics. In the aerospace industry, surface grinding is used to prepare turbine blades and other components for assembly. In the automotive industry, it is used to prepare engine blocks and other parts for further processing. In the medical industry, surface grinding is used to prepare surgical instruments and implants for use.

Aerospace industry

Many aircraft parts need to be carefully manufactured and have very tight tolerances. For example, turbine shafts on aircraft require precision ground parts. These turbine shafts serve as an emergency power source in the event of engine damage and require the precision and consistency that precision grinding provides.

Automobile industry

Automotive parts, especially engines, must be manufactured to precise dimensions or they may cause safety issues in the vehicle. An example of an automotive part that requires precision grinding is a cylinder head. Although milling is the typical technique for manufacturing these cylinder heads, precision grinding is also suitable due to the efficiency of the process.

Electrical industry

The electrical industry is another area that requires precision manufactured parts. For example, semiconductor wafers used in electronic components require precision grinding processes to produce the optical films used in these wafers.

Tips for Improving Surface Grinding

Some surface grinding shops are equipped with optimized machines, coolants, and dressing capabilities for high-volume manufacturing. But over time, had to contend with older machines and a lack of coolant and wheel dressing capabilities. This can lead to an inefficient grinding process and poor part quality. AN-Prototype summarizes some advice on grinding wheel selection and tips on grinding parameters that may help improve part quality and remove some of the complexity of surface grinding.

Choose crisper abrasive grains

One of the most common mistakes in surface grinding is using a grinding wheel with an abrasive grain that is too durable. If a durable abrasive grain is used, more force is required to break the grain apart so that a new sharp point is exposed and the cut is allowed to continue. Otherwise, under low pressure, the durable particles will not break; instead, they will become dull and rub against the metal repeatedly instead of cutting it. High-frequency friction causes chatter, burns, or poor surface finish due to heat.

During surface grinding, since the depth of cut is even less than 0.001 inch, this may not generate enough force to effectively break up particles that are too durable. In this case, the force is too low to effectively break the grain, trimming is required to resharpen the grinding wheel, and sufficient coolant is needed to cool the grinding area. However, if dressing and/or coolant are not available, it is critical to use a grinding wheel with a more friable grain.

Choose the right grinding wheel

While ceramic grinding wheels are considered superior technology and offer excellent material removal rates, they are not always ideal for surface grinding applications for a number of reasons.

Ceramic particles are generally slightly more durable than traditional aluminum oxide particles. Even highly brittle ceramic particles are stronger and more difficult to break than highly brittle alumina particles. While this is one of the reasons for a ceramic upgrade (because the stronger ceramic particles allow it to last longer and not break down as quickly), ceramic grinding wheels are actually too durable for surface grinding applications for the reasons stated above.

This doesn’t necessarily apply to all types of surface grinding/materials/parts, but if the grinding process using a ceramic wheel generates heat, you may need more friable ceramic particles, or you may switch entirely to friable traditional alumina particles Might solve this problem.

Reduce step size

Many surface ground parts have a wider surface area than a grinding wheel. For example, the part could be a 10′ x 10′ aluminum plate ground with a 5-inch wide grinding wheel. In order to grind the entire surface, the grinding wheel needs to make multiple moving passes, or cuts. These cuts can all be made in the same direction, or they can be ground in both directions, alternating between upper and lower cuts.

When making these movement paths, there needs to be a slight step-over from one grinding path to the next, which means that the second cut slightly overlaps the first to ensure continuity of grinding. Without stepping, some material between the channels may not be ground if the grinding channels are not perfectly aligned.

Based on AN-Prototype’s many years of experience, in this case it is better to have a smaller step amount, such as 20% or less, to minimize the area of the part to be regrinded. Additionally, reducing the stepover amount will require fewer passes to grind the entire part, thus reducing overall cycle time, which is an added bonus!

Get high-precision grinding services

At AN-Prototype, we have the in-house precision machining technology and equipment to complete your project. Our professional machinists have years of precision grinding experience and skills to meet your design specifications. Furthermore, we guarantee to provide high-quality, precise, durable, and affordable precision machined parts in any quantity. Contact us today for one-on-one support and you’ll get a response within 12 hours.