SLA and SLS are the two most popular processes in 3D printing services. Both use lasers to quickly create custom parts. Many companies or design enthusiasts have trouble deciding between the two processes, or even know the difference between them. Both SLA and SLS have unique advantages, but they differ in terms of printing materials, laser energy, speed, accuracy, price, etc. A major advantage of SLS over SLA is the time it takes to manufacture the part. SLS has shorter delivery times. As a result, more prototype parts can be produced every day. However, if precision details are important, SLS would be the best choice because it can manufacture parts with tighter tolerances. In this article, we will help you understand the differences between SLA and SLS and provide you with constructive suggestions for choosing the right process to create prototypes.

Table of Contents

ToggleWhat is SLA?

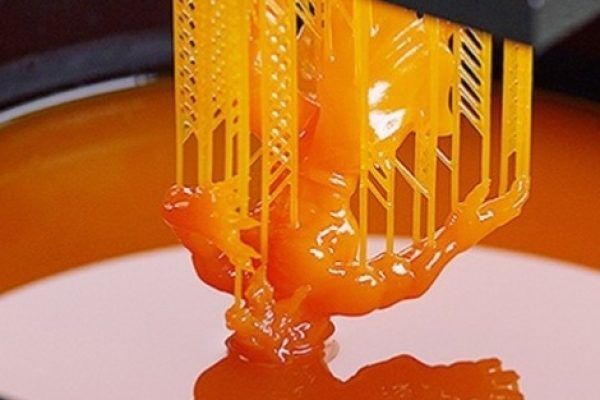

SLA is one of the earliest 3D printing technologies, also known as stereolithography. It is a technology that uses laser (ultraviolet) to solidify liquid resin to create customized parts layer by layer. Of all 3D printing (additive manufacturing) technologies, SLA parts offer the highest resolution and accuracy, the sharpest detail, and the smoothest surface finish, making them ideal for creating complex and beautiful-looking prototypes.

How does SLA work?

Before printing, upload the STL file to the SLA printer and preset thickness, angle and other details. Then, pour enough SLA resin into a clean pool of material. When an SLA printer begins work, computer-controlled mirrors guide the laser to the correct coordinates, scanning and solidifying the shape of the 3D design. After one layer has cured, the print bed is lowered to a preset thickness, typically 0.1mm; the printer will continue to cure the resin until the part is built. After printing, the part needs to be rinsed with isopropyl alcohol (IPA) to remove any uncured resin from its surface. After the rinsed part dries, some materials require post-curing, a process that helps the part achieve maximum strength and stability. Finally, remove the supports from the part and sand the remaining traces of the supports to get a clean surface. Then continue with post-processing, ultrasonic cleaning, support removal, re-curing the printed part, sanding, sandblasting and painting, etc.

What is SLS?

SLS (Selective Laser Sintering) is a 3D printing technology that uses a laser to fuse together small particles of plastic, metal, glass or ceramic powder to form a solid part. SLA (stereolithography) uses an ultraviolet (UV) laser to cure (harden) a photosensitive resin into the desired shape.

How does SLS work?

SLS printers have a build platform, a powder bin, a recoat blade, high-energy laser, heater, galvanometer, and a powder feeder.

First step of printing: Preheat the build platform and powder bin to a temperature just below the melting point of the SLS material. The powder is dispersed in a thin layer on top of the build chamber platform. A thin layer of powder is dispersed across the build platform by a recoat blade, then a laser scans the shape of the powder layer, sinters it, selectively heats the powder, and fuses the old and new layers together. The unfused powder supports the part during the printing process, eliminating the need for dedicated support structures. The build platform is lowered to a certain thickness, typically between 50 and 200 microns, and the recoat blade will disperse a new layer of powder and repeat the process with each layer until the prototype part is complete.

The second step is cooling. There is an additional process after printing the prototype part, and that is cooling. Cooling time can take up to 12 hours depending on the size and number of parts. The cooling process protects printed parts from warping and optimizes mechanical properties.

The third step is surface treatment. Start by cleaning excess powder from the SLS printed part from the build chamber. These remaining powders can be recycled and reused, making the SLS technology cost-effective. Additionally, sandblasting, grinding, painting, and powder coating are all surface treatment options for creating custom SLS prototype parts.

Comparison between SLA and SLS

The SLA 3D printing process first appeared in the early 1970s, when Japanese researcher Dr. Hideo Kodama invented the modern layered stereolithography method, which uses ultraviolet light to cure photopolymers. The term stereolithography was coined by Charles (Chuck) W. Hull, who patented the technology in 1986 and founded 3D Systems to commercialize it. In 1992, the SLA process was upgraded, making it possible to manufacture more complex parts and to manufacture parts faster. Dr. Carl Deckard and Dr. Joe Beaman invented SLS technology at the University of Texas at Austin in the 1980s. These two additive manufacturing technologies are the oldest 3D printing technologies.

What are the advantages of SLA over SLS?

1.SLA prototype parts provide higher resolution than SLS prototype parts.

2. The surface finish of parts manufactured by SLA is better than that of SLS. SLA parts can be similar to injection molded parts.

3.SLA machines are smaller than SLS machines. As a result, SLA machines can be used as desktop devices, making them more flexible and convenient.

What are the disadvantages of SLA compared to SLS?

1.The maximum size of SLA printed parts is smaller than the maximum size of SLS parts

2. The materials in SLA are not environmentally friendly. The resin can produce an unpleasant odor and requires gloves and a mask when handling it. SLS, on the other hand, uses a polymer powder such as nylon, which poses little risk to the environment except for people with certain allergies.

3. Parts made with SLA are relatively weak compared to SLS. They are best used for proof-of-concept or experimental purposes.

What are the advantages of SLS over SLA?

1. SLS parts do not require support structures during manufacturing, while SLA parts do. The surrounding powder can be used to support overhang components. SLA components need to be designed with support structures or built in such a way that they are self-supporting.

2.SLS can make parts faster than SLA. This makes it more suitable for rapid prototyping services.

3. SLS manufactured parts are tougher than SLA parts, so they are more commonly used as functional parts.

What are the disadvantages of SLS compared to SLA?

1.SLS machines are more expensive than SLA machines.

2.SLS laser printers consume a lot of power. This is because SLS printers need to be completely enclosed and shielded. The laser beam in SLA uses less power; users can view prints while they are enclosed behind plastic or tinted glass.

3. The SLS machine is larger. They often occupy an entire laboratory bench. In contrast, SLA machines can be designed as desktop units.

SLS vs. SLA Key Attributes Comparison

Attributes | SLS | SLA |

Sensitive to UV light | No | Yes |

Rough surface finishes | Yes | No |

Limited materials | Yes | No |

Needs no supporting structures | Yes | No |

Fast production process | Yes | No |

Expensive machine | Yes | No |

Parts produced are only for experimental use | No | Yes |

The polymer resin material used in SLA is sensitive to UV light. Therefore, keep away from sunlight or any other light source containing ultraviolet rays. SLS materials do not have this drawback and do not require support structures during the manufacturing process.

SLA vs. SLS: A comparison of technologies

The working environment of the high-power laser in SLS is completely enclosed and the operator cannot see the print during processing. SLA laser output power is significantly lower, and installing a tinted glass or plastic casing on the device can prevent UV rays from escaping. The operator can see the entire printing process during processing.

SLA vs. SLS: Materials Comparison

SLA materials are considered photopolymers, which are thermoset resins in a liquid state. SLA has the widest selection of 3D printable plastics with excellent mechanical properties, including: ABS-like, polypropylene-like, polycarbonate-like, and more. SLS materials are derived from thermoplastic powders, but operators must wear gloves and masks when handling SLA parts, which is slightly hazardous. Compared to SLA materials, SLS materials can be used to build durable end-use parts, including: polyaryl ether ketone, thermoplastic elastomers, polystyrene, nylon, and more.

SLA vs. SLS: Product Application Comparison

SLS manufactured parts are stronger than SLA prototype parts. This makes them a better choice for machinery or end-use applications.

SLA vs. SLS: Print volume comparison

Due to the relatively short sintering time, SLS prints faster than SLA for both large and small prototype parts. Again, SLS does not require support structures during the construction of prototype parts.

SLA vs. SLS: Cost Comparison

SLS printers are generally more expensive than SLA printers. SLS printers cost between $10,000 and up to $650,000. The cost depends on the maximum build volume, minimum layer thickness, print speed, laser type, and the materials it can accept. On the other hand, SLA machines cost even less than $3000, depending on size. They can be divided into four different types: DIY, Advanced Hobby, Professional and Performance, and Commercial and Industrial. SLS generally costs more than SLA to manufacture prototype parts of the same size.

SLA vs. SLS: Surface Treatment Comparison

SLS parts typically have a rougher surface than SLA or other 3D printing technologies. However, the SLS part is more durable and more suitable for heat or chemical resistant environments. Printed parts differ between the two processes, as does the surface treatment. SLA prints need time to rest so remaining resin can drain; SLS prints need to cool before being unpacked. SLA prints are sticky and require cleaning; SLS prints require cleaning of excess powder when unpacking.

Choose SLA or SLS?

When choosing between SLA or SLS 3D printing services, certain considerations such as durability, resolution, or part size may make the decision for you. Understanding the key factors will go a long way in choosing which process will work for you.

Surface Finish: SLA will build parts with a high quality, smoother surface finish that more closely resembles injection molded parts.

Resolution: SLA offers higher resolution compared to SLS. AN-Prototype’s SLA 3D printing services offer three resolution options so you can balance detail and surface finish quality with cost.

Tolerances: SLA is capable of tighter tolerances than SLS.

Heat and chemical resistance: Thermoplastic SLS materials have better overall heat and chemical resistance than SLA parts.

Design Complexity: If your project requires complex details, an SLA may be a better choice. However, if your design requires mechanical strength and more functional properties, SLS may be the appropriate technology.

Material Selection: While both SLA and SLS offer a wide range of materials, SLS has the edge when it comes to material selection. It can be used with thermoplastics, composites and even metal powders, providing more options for specific project needs.

Production Volume: If you need some high-quality prototypes or individual custom parts, SLA can meet your needs with its high precision and surface finish. For larger production volumes or small batches, SLS can provide a cost-effective solution.

Conclusion

Stereolithography (SLA) and Selective Laser Sintering (SLS) are two revolutionary 3D printing services that bring huge value to different industries. Each technology has its advantages and ideal use cases. SLA technology excels in prototyping, visual models, and dental applications, while SLS performs even better in functional prototypes and low-volume manufacturing. AN-Prototype will carefully evaluate your 3D printing project, guide you in choosing the most appropriate technology, and provide the best advice in terms of accuracy, strength, surface finish and cost-effectiveness.