Metal-based products are widely used in almost all applications. Every industry depends on metal for some or the other thing, and the different forms of metal have different processes through which it can be shaped and manufactured. Sheet metal fabrication is also a popular method for manufacturing metal-based products. As the name suggests, the sheet metal fabrication process uses sheet metals to design and develop the products. The guide below comprises detailed information on the process of sheet metal fabrication. If you look forward to knowing more about this topic, you are at the right place, so let’s read below.

Table of Contents

ToggleWhat is Sheet Metal Fabrication?

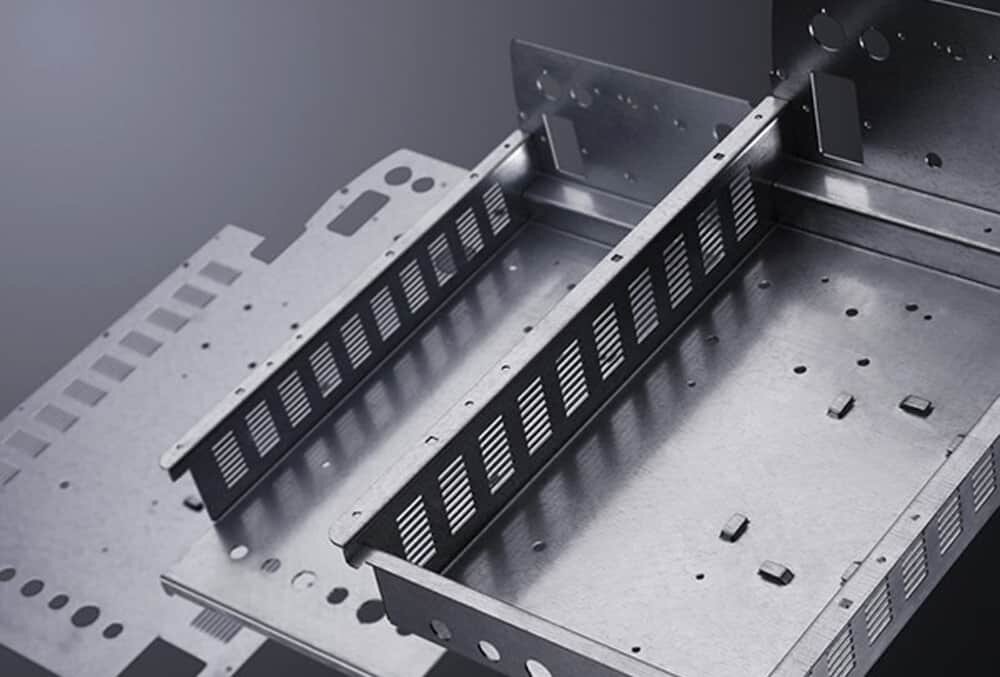

Sheet metal fabrication is a process to turn the sheets of metal into the required designs and layouts to process them for creating products. This process comprises bending, cutting, and assembling metal sheets to attain the desired shape of metal used in the product with relevance.

The metals used in sheet metal fabrication are various, comprising aluminum, stainless steel, steel, copper, brass, zinc, and others.

The metal in the form sheets may vary in terms of thickness; this includes 0.006 to 0.25 inches. The thinner sheets are suitable for basic applications, and thicker ones are opted for applications that need to produce heavy-duty objects.

Different techniques are opted for by manufacturers to create the components using sheet metal parts in association with sheet metal fabrication. Multiple methods are used at a time to produce the required products. However, the basic processes include cutting, joining, and finishing the product.

Sheet Metal Fabrication Technique

The process of sheet metal fabrication leads to converting the metal in the form of the sheet into a component needed for a specific application by shaping it. However, the entire process of sheet metal fabrication has different stages, and they are discussed below:

Sheet Metal Cutting Techniques

Cutting techniques used in sheet metal fabrication are opted to cut down the metal sheets in needed sizes and layouts. There are different cutting techniques, and the section below details these techniques.

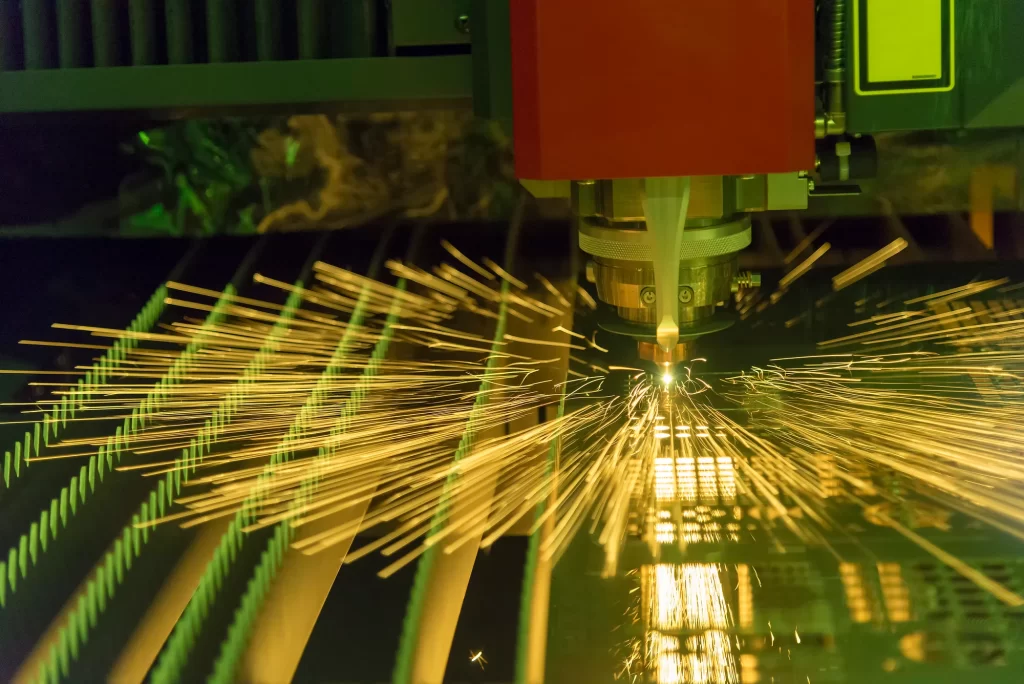

Laser cutting uses a thermal process for cutting in which, using laser beams, and the metal is melted and cut down. This process comprises two distinct methodologies. The first one uses a laser beam at high power, and it causes the metal to vaporize when subjected to the high beam of laser.

The other method uses blowing gas, which may be oxygen or nitrogen, which helps protect the process from metal splashes. It is also ideal when it comes to removing the material that is in excess from the kerf.

The laser cutting process uses different metals, comprising all kinds of steel and non-ferrous metals. However, aluminum cutting is a little tough because it is reflective. The usual thickness of metal sheets supported by this method is between 20mm to 40mm.

The laser-cutting process is ideal for industrial applications and is very efficient and flexible. It also offers extreme accuracy and comprises more energy and gas; hence, it is an expensive method.

Plasma Cutting

Plasma cutting is a process of cutting metal sheets that uses ionized gas. This process applies a huge amount of heat to the metal sheet, melting it. The result of the process comprises an uneven cut.

Plasma cutting is a method of metal sheet fabrication that goes well with materials with electrical conductivity. It helps to cut the aluminum, copper, brass, and stainless steel metal sheets that have a moderate level of thickness.

The process of plasma cutting leads to immediate cutting, offering highly accurate cuts, and is also equipped with automated processes. One problem with this process is its high energy consumption; sometimes, it also causes a lot of noise during the cutting process.

Waterjet Cutting

As the name suggests, this process of waterjet cutting involves using water. The cut on the metal sheets is made by passing through the pressure of the water stream, which is relatively very high, around 60000 psi. This method is suitable for cutting all kinds of metal sheets.

The process itself is very versatile and can cut materials that are hard as well as soft. The materials commonly opted to pass through the water jet cutting process of aluminum, stainless steel, carbon steel, and copper.

The best thing about this process is that it doesn’t damage the edges nor give an unfinished result. It offers an excellent finish; hence, the component has no heat marks.

Shearing

Another technique that involves cutting metal sheets in the sheet metal fabrication process is the method of shearing. It separates the materials by cutting them and is suitable for applications requiring a high volume of components.

This method is suitable for soft materials; the edges of the sheets after cutting may be rough, but some applications need that straight and uneven edge. However, it is one of the most affordable cutting methods and helps produce a high volume of components in a concise span of time.

The process may, however, lead to the deformation of the material, and hence, the applications where components with a very neat finish are needed, this process may not be suitable.

Blanking

Blanking uses the punch and die technique, where a huge piece of metal is removed from another huge piece. The die in the processing equipment holds the metal sheet, and through a blanking force, a punch leads to the removal of the material.

This process is a suitable one when it comes to manufacturing customized components, and the level of accuracy offered is also commendable. However, the tooling cost is high and takes a lot of time.

Punching

The punching process applies force on the sheet metal that creates holes, and the metal leaving the sheet appears to be scrap, and the material left behind on the die is the component designed.

The holes created through this method can be of different sizes and designs, and it is a speedy process that leads to a huge volume of parts in a limited time. Moreover, the workpiece doesn’t get any deformations as the process is not thermal and hence doesn’t make any metal part melt.

Sawing

Sawing is a method involving a sawtooth, and it helps make cuts in the metal. This process leads to applying force, which removes the small chip of material from the entire sheet.

Several teeth-like bends help marginally cut metal sheets in desired sizes and layouts. The metals suitable for this task are brass, copper, aluminum, etc. It has horizontal and vertical saws; the horizontal ones help cut the longer areas, and the vertical ones are ideal for complex and accuracy-oriented cuts.

The best thing about these saws is that they can cut straight and have many advanced features to help ensure precision cutting.

Sheet Metal Forming Techniques

The stage of sheet forming in sheet metal fabrication tends to reshape the materials that are in their solid state. There are different methods and techniques through which the sheet metal can be transformed into desired shapes, and they are discussed below:

The bending process involves transforming the metal sheet to a desired angle to achieve a desired shape. The machines used for this process comprise rolling and press brakes.

Rolling machines help roll the sheet metal in the given ranges, and the press brake uses a punch and die to bend the metal sheet.

There are different methods for bending metal sheets, including v-bending, roll bending, U-bending, wipe bending, and rotary bending. The bending process is suitable for malleable materials, and this usually consists of opting for mild steel and some forms of aluminum and copper.

Bending is a suitable process in terms of cost savings provided that the production volume is moderate and it gives metal parts exemplary mechanical properties.

Hemming

The hemming process comprises two distinct stages: the first bends the metal sheet in a V-shape, and the second eliminates excessive metal and flattens it to give the required shape.

The hemming process is suitable for enhancing the appearance of the parts by carrying out edge reinforcement for the parts manufactured.

The surface quality of the parts can be enhanced through this process, and it makes components have dimensional variations.

Rolling

The process of sheet metal rolling consists of making the metal pass through rollers, and it helps make the material thinner uniformly. The rollers create a force on the material, which leads to deforming the material, and they do this by flattening the material.

The rolling process is divided into two processes: the hot rolling process and the cold rolling process. This process is usually observed in applications where rolled metal sheets are used, like stampings, wheels, rims of wheels, discs, tubes, etc.

This process is very quick and carries out the task with efficiency. The parts needing tight tolerance and complexities are usually designed using this process. However, it needs a hefty initial investment and is ideal for high production volume.

Stamping

The stamping technique used for sheet metal fabrication is a cold press technique, and it uses dies, which leads to the transformation of raw sheets of metal into different shapes. This process is suitable for many kinds of sheet metals, which consist of high and low-carbon steel, stainless steel, brass, copper, and aluminum.

Stamping is a method that uses different techniques to create many designs and shapes of components with complex dimensions and layouts. This method is affordable and needs less tools and labor and hence is a fast method to manufacture different components.

Curling

Curling, as the name suggests, is a method that helps add curricular rolls in the hollow metal sheets. This process of curling is based on three different stages.

This technique helps to eliminate the edges from the component, which are sharp by curling them and also adds strength to the component. However, this process must be performed carefully because it may lead to some deformations.

Metal Spinning

The process of spinning requires him to create discs made out of metal. The material is placed in the tailstock, and the shape is given through spinning. A spinning roller in the middle of the machine rotates and shapes the metal.

This process is suitable for metal places, which are made using materials like brass, copper, aluminum, and stainless steel, and it even allows the production of parts with hollow designs. This method could be combined with other techniques like punching and bending to achieve the desired shape and design.

Sheet Metal Welding Techniques

Sheet metal fabrication has a very important process known as the welding technique, which helps to combine metal sheets into two pieces. This process of welding companies uses pressure and heat to carry out the welding process, and there are different ways metal sheets can be welded together.

Stick Welding

The process of stock welding uses an electrode stick; this stick is used to create an arc as soon as it comes in contact with the metal sheet and uses electric current for this. The arc produced needs a temperature of more than 6300 Fahrenheit in order to let the metal melt.

This welding technique is suitable for welding, is associated with high speed, and works well with power sources that may be DC or AC. However, you need to exercise care when using this welding, which is nice because the high temperature may cause damage to the sheet of metal.

Inert Gas Welding

This welding process uses a shielding technique from a wire electrode. The electrode helps the joining of metal sheets, and the welds created out of it are high-quality welds that take less time due to their effect speed. This welding technique is suitable to opt for thinner sheets of metals.

TIG Welding

TIG welding stands for tungsten inert gas welding, and this process leads to a shorter arc and is used to weld heavy metals. The electrode used in this kind of welding is made of tungsten, and it also comprises an inert shielding gas.

The best thing about this welding method is that it suits metals like titanium, copper, and aluminum. This process is suitable for the aerospace and automobile industry, but it needs a highly trained professional to carry out the process.

Sheet Metal Fabrication Tolerance

In the sheet metal fabrication process, knowing the acceptable tolerance level is essential, and understanding it will help with better and more precise results. Tolerance in sheet metal fabrication is understanding the acceptable variation in terms of features of the sheet metal part being designed or its dimensions.

Some of the common tolerance levels in sheet metal fabrication are as follows:

Dimensional tolerance specifies the allowed variations in dimensions of the component manufacturing, including width, length, diameters for hollow parts, etc., which could be between +0.1mm and -0.1mm.

The acceptable deviation in terms of angles and bends of the acceptable component is between =1 degree or -1 degree.

The layout of the component manufacturing comprises its flatness and curved composition of a variation parameter tolerable to the extent of 0.2mm to -0.2mm.

Design Tips for Sheet Metal Fabrication

The sheet metal fabrication process is meant to enhance the component’s layout, design, and functionality, and to improve its design, you can follow the below-suggested tips.

Thickness of Wall

The components manufactured through the process of sheet metal fabrication should have a uniform wall thickness. The thickness usually manufactured from sheet metals is generally greater than 3mm. Every procedure offers a different thickness range; laser cutting may be between 0.5 to 10mm, and sheet metal bending is between 0.5 to 6mm.

Bends in the Component

The number of bends in the sheet metal fabrication process depends on some parameters, and these are discussed below:

K-factor is an important consideration that helps avoid sheet metal deformation and tearing. The range of bending, in this case, should be between 0.3mm to 0.5mm. Hence, calculating the k-factor helps to find the right allowance for the edge and is calculated by dividing the neutral axis by the thickness of the material.

Bend radius is also an essential consideration because the small radius may cause strain on the component and should be avoided. Hence, metals like stainless steel should have a bend radius similar to metal thickness, and brittle metals may have a larger bend radius.

The bend orientation should be consistent to reduce the lead time and cost of manufacturing.

Bends that are too close to the edge of sheet metal may lead to deformation; hence, by adding reliefs to the design, the risk of components tearing later on is eliminated.

The bend height should be more than the thickness of the material opted. It should be double thickness to enhance the component’s quality.

Hems

When manufacturing components using sheet metal, it is suggested to avoid flat hems. Having tear-dropped or open hems is preferable as they do not deform easily. Moreover, the diameter of the inner part of the hem mutts has the same thickness as the sheet metal, and the length should be four times the thickness of the metal sheet.

Diameter Size for the Hole

The diameter of the holes in the component and the thickness of the material should be the same; even if the diameter is larger than the metal sheet thickness, it is also far much better. It leads to reducing the damage risk and also helps to reduce the time and cost minimized.

The space within the hole should also be double the thickness of sheet metal so that no deformation can occur. The holes should also be away from the edges to prevent tearing.

Curls of the Metal Sheets

The outer radius of the curl in the component should have a thickness double the material opted to manufacture a component. This process of curling adds up to a hollow roll on the edge.

By curling the edge, strength is applied to the component, which appears safe to handle. In this case, the hole size should be less than the radius of the curl and the material thickness.

Similarly, when it comes to countersink depth, it should be more than 0.6mm of the thickness of the material. Also, the distance between the countersink centers should be at least 8 times the thickness of the material.

Notches and Tabs

The length of tabs at the maximum should be 5 times the width and double the material thickness. Moreover, the notches, on the other hand, should have a width the same as the thickness of the material.

The placement of the notches should have a minimum distance of one-eighth in between. The tabs and notches should be kept away from the bend to reduce the chance of any deformation or damage.

Sheet Metal Gauge

One of the major considerations in sheet metal fabrication design is the sheet metal gauge. The material’s thickness depends on the layout and application of the part. The very thick sheet metals will have a limited bend angle.

Moreover, when the bends are sharp, they may cause cracks in the metal; hence, they are costly and take longer to produce. Hence, thinner materials are primarily suitable.

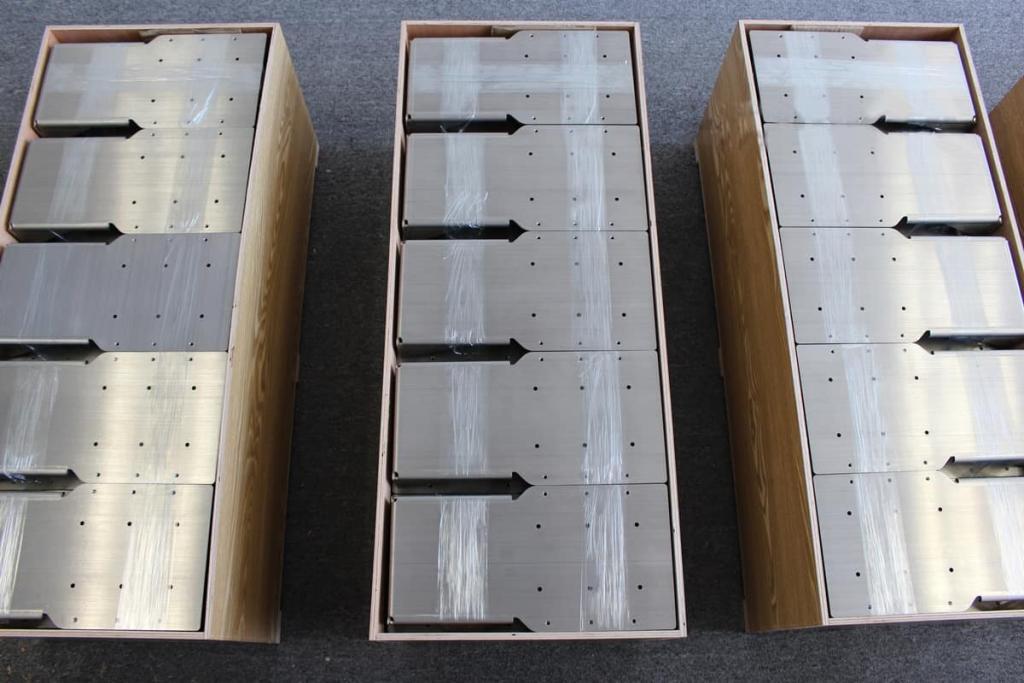

Materials Sheet Metal Fabrication

The process of sheet metal fabrication can be carried out with multiple materials. However, the selection of material highly depends on the application as it is a consideration on which the physical properties of the component will depend.

Some of the commonly adopted materials used in the process of sheet metal fabrication are as follows:

Stainless Steel

Stainless steel combines different materials and contains chromium, which offers resistance against corrosion, making it suitable for sheet metal fabrication. Stainless steel is one of the most durable materials, providing unmatchable strength.

The typical applications of stainless steel are the construction industry, the automobile industry, fuel containers, and most cooking utensils.

Hot Rolled Steel

Hot-rolled steel is also a form of steel that is suitable for the process of sheet metal fabrication. It is suitable in applications where surface finish and tolerance in terms of dimensions are not a problem. It is suitable for all kinds of structural applications, including car components, agricultural machinery, frames of automobiles, etc.

Cold Rolled Steel

Cold-rolled steel has a higher strength as compared to hot-rolled steel. When the final component’s quality needs to be high, cold-rolled steel proves to be the suitable option. It offers a shiny finish, has a smooth texture, and is suitable for aesthetically appealing applications. It is commonly used in lighting fixtures, automobile components, home appliances, etc.

Plated Steel

The plated steel is composed of a zinc coating that helps to offer resistance against corrosion. It increases the component’s life and ensures that the steel can be processed easily in terms of weldability and formability. It is widely used in many equipment manufacturing processes.

Aluminum

Aluminum is a metal which is known for its strength and lightweight properties. It is used in combination with other metals and tends to make alloys. The commonly used aluminum alloys for sheet metal fabrication are 5052 and 6061.

It offers quick machinability and is also resistant to corrosion. It is also a good conductor of electricity and heat and is used for many applications like aerospace, automobile, enclosures, medical equipment, electrical products, etc.

Brass and Copper

Copper is widely used for sheet metal fabrication due to its excellent bendability. It is a malleable material and can be shaped by rolling and hammering it. It doesn’t corrode, and components that are subjected to corrosive chemicals may be manufactured using copper as it doesn’t wear out.

Brass, on the other hand, is also used in many sheet metal fabrication processes. Brass is also a material that is resistant to corrosion, capable of handling high temperatures and is used widely for its high level of electrical conductivity.

There are many applications of brass and copper in sheet metal fabrication, which include electronic equipment, bolts, pipes, fixtures, and kitchen utensils.

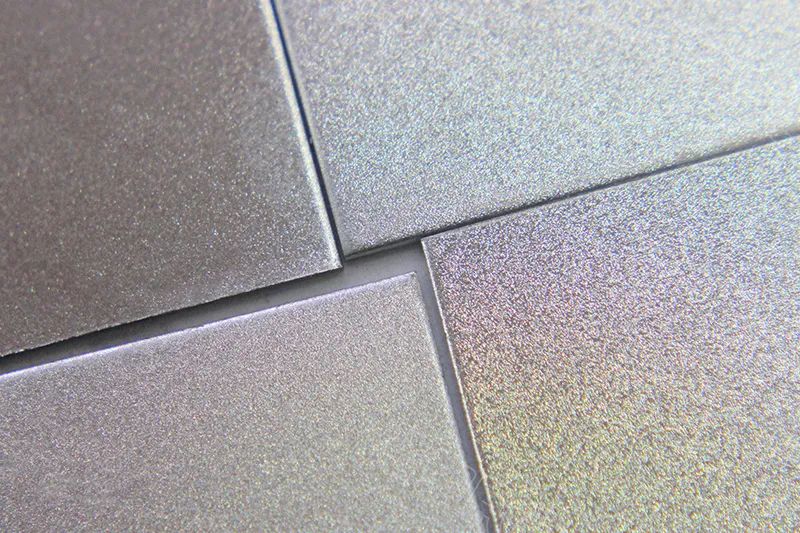

Surface Finishes for Sheet Metal Fabrication

Some components, after being manufactured through the process of sheet metal fabrication, are subject to surface finishing, and some of the types of surface finishing available in sheet metal fabrication are as follows:

Bead Blasting

The bead blasting finishing process uses glass or sand beads, which are shot on the components, and the way they hit the components, a smooth surface finish is applied.

This finishing process gives the component an excellent and smooth finish and doesn’t impact the dimensions. It is suitable for finishing metals like copper, steel, and aluminum, enhancing the component’s durability.

Powder Coating

To add finishing on the surface of the components manufactured using sheet metal fabrication may have enhanced finishing by spraying a powder paint on the surface. After the powder paint is applied, the component is left to be baked to create a layer of material on the surface, which adds resistance against wear and tear and corrosion.

Powder coating is ideal for sheet metal fabricated parts because it adds durability and offers resistance against heat, making them suitable for all kinds of weather conditions as well.

The sheet metals like aluminum and stainless steel, when used for manufacturing components through sheet metal fabrication, are usually finished using powder coating.

Anodizing helps convert the metal surface layer into an oxide layer. This form of anodizing is highly compatible with titanium and aluminum. There are different types of anodizing processes.

Type 1 helps create a thin layer on the surface of the metal using chromic acid. Type 2 tends to use sulfuric acid, and the layer created using it on the metal surface makes it corrosion-resistant and strong. Type 3 adds a thickener finish, which makes it resistant to corrosion.

Anodizing is widely used in aerospace and automobile parts and other precision instruments. It helps enhance the aesthetic of the sheet metal parts and makes them resistant to corrosion.

Laser Engraving

Laser engraving, as the name suggests, is a surface finishing process that helps engrave the required image or text on the metal component. It is mainly opted to personalize the component.

The process uses a laser to add the coating on the component, and it is suitable for materials like stainless steel, aluminum, and carbon steel.

Brushing

The surface quality of the metal component is enhanced after the sheet metal fabrication process using filamentary brushes. The process of brushes helps to remove the burrs which some of the metal sheet fabrication processes may leave behind on the component.

This process is also helpful in eliminating the marks of rust, paint, and welding from the manufactured components.

Screen Printing

Screen printing helps to apply ink on some areas of the metal component. This process uses a blade and a polyester mesh to do the job. The stencils are designed to protect the areas where the ink shouldn’t reach while the process is being carried out.

Screen printing is a cost-effective process used widely instead of engraving and painting.

Applications of Sheet Metal Fabricated Parts

Sheet metal fabricated parts are manufactured for numerous applications, and some of these are as follows:

The aerospace industry needs components that require high tolerance and precision. Hence, numerous components that are suitable for space use and are lightweight are manufactured using sheet metal fabrication processes. It is an affordable process and also helps produce complex aircraft parts.

The automobile industry uses numerous components which are manufactured through sheet metal fabrication. The thin sheets of metals manufacture the roof, hood, and panels used in the vehicles.

The healthcare sector uses components manufactured through sheet metal fabrication, and the tools used in the healthcare industry need to be highly accurate and of high quality. Hence, this process is used to manufacture automated tools suitable for certain essential functions. MRI applications depend on stainless steel and aluminum because they do not impact magnetic fields.

Every appliance is made using metal, and to ensure high-quality appliances, the sheet metal fabrication process helps to manufacture these appliances and their enclosures. The appliances manufactured through sheet metal fabrication are blenders, capillary tubes, and other equipment.

Electronic products like drones, cell phones, tablets, and LED lights are manufactured through metals, and this sheet metal fabrication process is opted for. Laser and waterjet cutting are mainly opted for because they ensure a quick and affordable processing method for electronics.

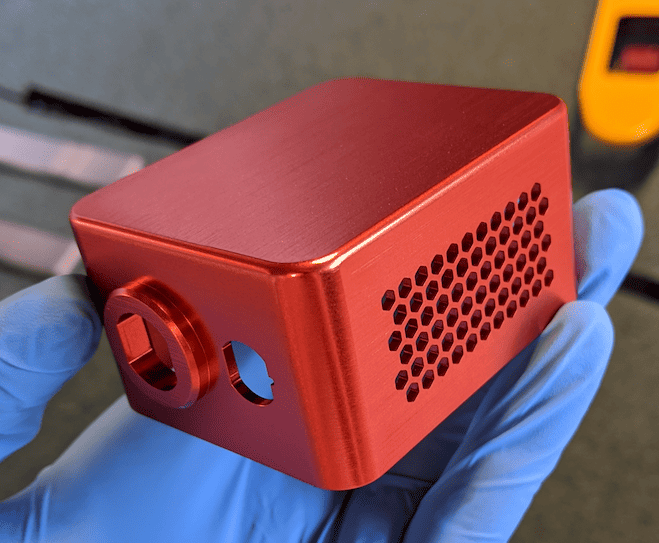

Most of the electronic products are enclosed in metal enclosures, which are also manufactured using the process of sheet metal fabrication. These enclosures help protect the equipment inside, which usually counts for LED panels, HDMI boxes, light pipes, etc.

8 Tips to Reduce Sheet Metal Fabrication Costs

To reduce the cost of sheet metal fabrication, you can follow some essential tips as suggested below:

Selection of Appropriate Raw Material

When the right material is chosen according to the application, it helps in cost reduction. Moreover, there are options where you can choose low-cost materials like hot rolled steel and carbon steel, which are affordable compared to other options.

Most of the raw materials even have alternatives; for example, instead of stainless steel, you can choose aluminum. It has the same properties and helps save the cost of manufacturing. Also, a plated material is a better choice for certain environments because it offers resistance against rusting and saves the cost of further surface finishing processes.

Opting for Standard Sheet Gauge

Standard gauge and sheet size are always the best options when designing any metal component. If you opt for ordering unique sheet gauges, you will pay more. The standard ones are readily available; hence, no customization is involved, which leads to increased costs.

Eliminate the Need for Welding and Plating

You can reduce the cost of sheet metal fabrication by eliminating the need for welding and plating. The two of these processes tend to increase the cost of manufacturing; hence, when you avoid them, you can save on costs.

Keep Designs Simple

The aesthetic value of the complex designs can never be eliminated, however, they add to the cost as well. Hence, when it comes to managing the costs, it is suggested to keep the designs simple, and it will ensure that the process also is simple.

When there are too many bends and cuts, the processing and more tooling take time, which adds to the cost of the final product due to increasing manufacturing costs. Hence, it is suggested to keep the design simple to save the price.

Focusing on the Bend Radius

The cost of sheet metal fabrication can be reduced by focusing on the right geometrics in the design of components. The internal bend radius should be around 0.762mm compared to material thickness. It helps to keep the tooling process simple and manufacturing costs lower.

Consider Tolerance Appropriately

The features, which consist of tighter tolerance, increase the manufacturing cost of a component. Hence, it is essential to be considerate about the tighter tolerance. It is because such components lead to the wear and tear of tools due to strain, so the need for tool replacement is quite frequent.

Avoid Custom Design Fasteners

Fasteners with a fancy customized design may cost more when it comes to manufacturing. Hence, opting for designs that do not need any customization is suggested to save on manufacturing costs.

Opt for Reasonable Finishing Options

There are countless finishing options, each with a separate cost. Hence, depending on the cost, you can choose the finishing option. Some finishing options like engraving and screen printing are costly, so these could be avoided.

Moreover, some materials are of such nature that they do not corrode; hence, they do not need any further finishing. Opting for them could be a cost burden and can be avoided.

Conclusion

As you have gone through a detailed insight into sheet metal fabrication, you now will have a lot of information on this method of manufacturing components. It has a detailed guide on the processes, material, and finishing options you will come across when opting for sheet metal fabrication.

So, if you are looking to have the components manufactured through sheet metal fabrication, you can get in touch with AN-Prototype. You will get a chance to have a versatile connection of metal parts manufactured using this process that is of high quality and offers affordability. So, contact us today.

FAQ

1.What tools are commonly used in the process of sheet metal fabrication?

Ans. The tools used to manufacture components using sheet metal fabrication include angle grinders, cutting glasses, darkening helmets, wire cutters, etc.

2.What are the common methods used for sheet metal fabrication?

Ans. The sheet metal fabrication process is equipped with some methods, which include turning, drilling, cutting, casting, punching, etc.

3.What is the maximum level of acceptable thickness in the sheet metal bending process?

Ans. sheet metal plates are usually in a thickness which varies between 0.005 inches to 0.249 inches; in the case of aluminum and steel sheets, the minimum thickness is 0.250 inches, and the maximum is 13 inches.