In today’s fast-paced manufacturing environment, rapid tooling has become a fast tool for customized products. This article explores the world of rapid tooling, its various types, benefits, limitations, and applications as well as an in-depth look at how rapid tooling differs from traditional tooling and how rapid tooling is uniquely positioned compared to rapid prototyping. Find out how this innovative approach is providing faster production cycles, cost-effective customized solutions for a wide range of industries.

Table of Contents

ToggleOverview of Rapid Tooling

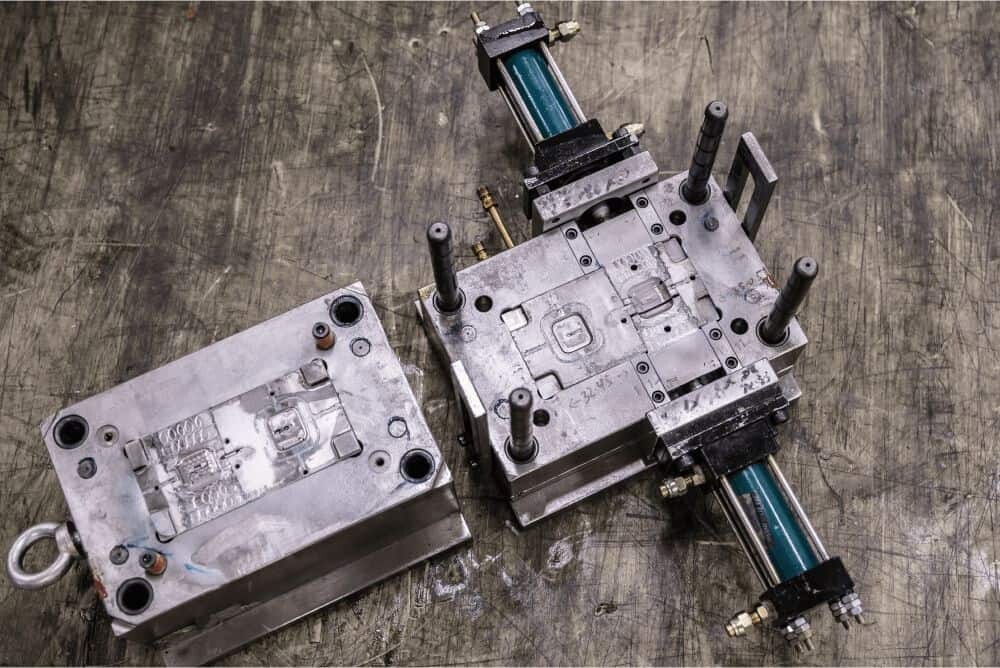

Rapid prototyping is the process of rapidly producing molds and tools for use in manufacturing. It is a key component of the Rapid Manufacturing methodology to produce functional parts and prototypes faster and more efficiently. Rapid tooling plays a vital role in bridging the gap between rapid prototyping and traditional tooling methods, providing a cost-effective and time-saving solution.

The primary goal of Rapid Tooling is to accelerate the tooling production process, enabling manufacturers to quickly transition from the design phase to actual manufacturing. By utilizing advanced technologies such as Additive Manufacturing and CNC machining, Rapid Tooling is able to create molds and tools with greater precision and shorter lead times.

The applications for rapid tooling are varied and cover industries such as automotive, aerospace, consumer goods and medical devices. It allows for the production of customized parts, small production runs, and rapid iteration of designs. Rapid prototyping allows manufacturers to respond quickly to market demands, reduce time-to-market, and gain a competitive advantage in their respective industries.

Comparing Rapid tooling and Traditional tooling

Rapid tooling is a group of technologies used to quickly, cost-effectively and efficiently create tools for traditional manufacturing processes to make parts in a shorter period of time or in lower quantities.Traditional tools are usually made of durable metals using techniques such as machining and metal casting. However, these processes are expensive and more suited to mass production cycles. When used for tooling iterations or to produce tooling that is only used to make small batches of parts, costs can rise and production times can increase dramatically.

Integrating rapid tooling into the product development process allows manufacturers to validate designs and material choices before transitioning to mass production to accelerate product development, iterate quickly, and bring better products to market. Rapid machining enables engineers to use actual production-grade materials to evaluate the performance of parts in real-world applications and produce limited quantities for beta and validation testing. Rapid tooling can also help troubleshoot the manufacturing process before investing in expensive production tooling.

Additionally, rapid tooling provides a way to produce custom or limited series of end-use parts using traditional manufacturing processes that would be prohibitively expensive to use. This allows manufacturers to test new products for the market, offer a wider range of products, or customize parts to customer needs. Please see the table below:

RAPID TOOLING | CONVENTIONAL TOOLING | |

Speed | 24 hours | 4-8 weeks |

In-house production using additive manufacturing techniques | Outsourced production | |

Tooling cost | Low costs, similar to rapid prototyping, low overhead costs | Very expensive, considerable overhead costs. |

Ideal production volume | 1 – 10,000 parts, depending on the process and tooling material | ~5,000+ parts, varies by production process |

Applications | Prototyping | Mass production |

Product validation testing | ||

Bridge tooling | ||

Short run, on-demand, or custom production |

What materials can be used for rapid tooling?

Rapid prototypes are temporary molds used to produce prototypes, small batches of parts, or cast resins. Some common materials used for rapid prototyping including silicone rubber, polyurethane, plaster and metal.

Aluminum

Aluminum is the material of choice for rapid prototyping due to its excellent thermal conductivity, making it ideal for injection molding. It is readily available and offers a good strength-to-weight ratio.

Steel

Steel, especially tool steel, is a reliable choice for rapid processing. It is durable and can withstand high pressure molding processes. China’s steel industry ensures a constant supply of high quality material.

Plastics

For certain small batch applications, plastics such as ABS or nylon can be used for rapid tooling. These materials are cost effective and ideal for prototyping.

Copper

Copper is used for certain specialized applications, especially for electronic components. It has excellent electrical conductivity and is easy to work with.

Manufacturing Technologies

CNC machining

CNC machining plays an important role in China’s rapid tooling industry. It involves the use of precision tools to subtract material from a solid block. CNC machining can handle a variety of materials, including metals and plastics.

EDM utilizes electrical discharges to precisely etch material. It is a precise method, often used for complex shapes or hardened materials.

In China fast-moving manufacturing environment, the choice of material and technology for rapid tooling can significantly impact product development and time to market. The choice depends on factors such as budget, project requirements, material properties and desired throughput. With further advances in technology, the range of rapid tooling materials and techniques will continue to expand, offering a range of new prospects for innovation and contributing to the growth of China manufacturing.

Types of Rapid Tooling

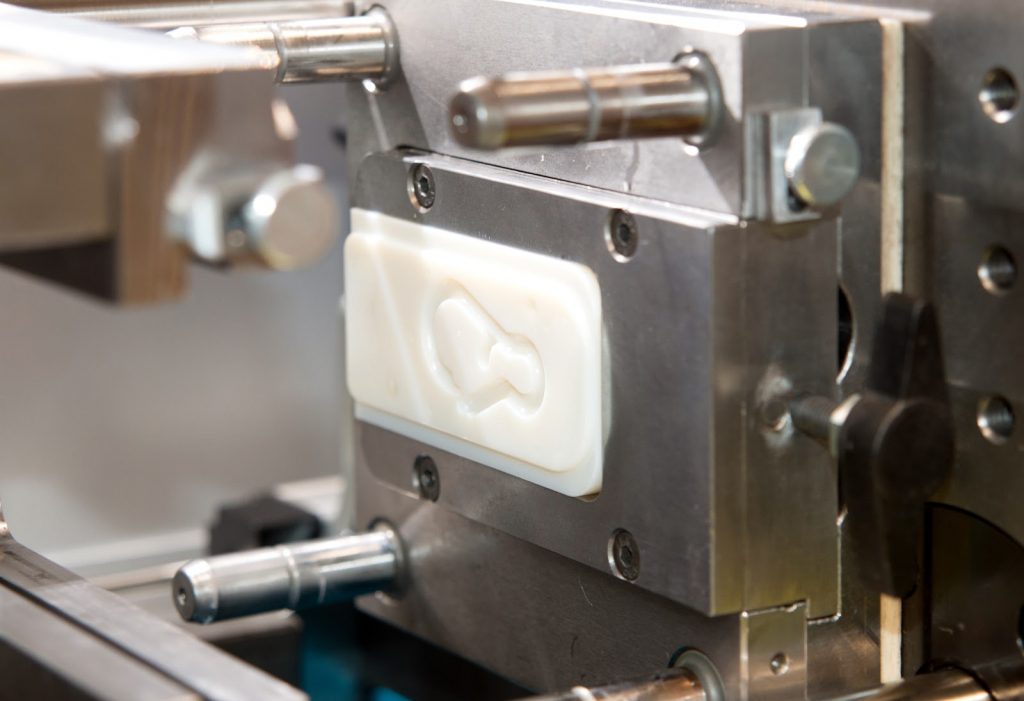

Rapid prototyping encompasses a variety of techniques, including direct rapid tooling (DRT) and indirect rapid tooling (IRT). DRT involves the direct creation of a mold or tooling using additive manufacturing techniques such as 3D printing or selective laser sintering. On the other hand, IRT involves the creation of master patterns or prototypes and then the generation of final molds or tools using conventional or additive manufacturing methods.

Direct Rapid Tooling

Direct Rapid Tooling creates actual core and cavity mold inserts. The advantage of this process is its ability to create tools with geometries that were previously unattainable. Conformal cooling technology is an example of this. In this technique, internal cooling channels follow the contours of the mold cavity, enhancing the uniformity of heat loss from the mold and reducing cooling times by approximately 66%.

In short-run manufacturing, this form of rapid tooling allows you to build a mold or tool very quickly and begin making products almost immediately. This is especially advantageous for short-term manufacturing because the tooling does not need to be very strong or long-lasting. Depending on the materials used and the complexity of the design, this mold can produce up to 5,000 parts.

Steps in Indirect Rapid Machining:

Design: Create a digital model of the mold part using CAD software.

Material Selection: Choose a suitable material for the mold component, such as aluminum or steel.

Manufacture: Produce the tool component directly from the selected material using CNC machining or 3D printing.

Finishing: Apply post-processing techniques such as polishing or surface treatment to achieve the desired surface finish.

Advantages of Direct Rapid Machining

Speed: Direct Rapid Tooling allows for faster production of tooling components and shorter lead times than traditional methods.

Design Flexibility:CAD software allows for complex designs and quick modifications for design optimization.

Cost-effective: Direct Rapid Tooling is more cost-effective for low to medium volume production than traditional tooling.

Disadvantages of Direct Rapid Tooling

Material Limitations: The range of materials that can be utilized for Direct Rapid Tooling can be limited compared to traditional machining methods.

Durability: Mold components produced through direct rapid tooling methods may have lower durability compared to mold components made using traditional mold materials.

Size Limitations:The size of the tooling components may be limited by the building envelope of the CNC machine or 3D printer used.

Indirect Rapid Tooling

Indirect Rapid Tooling utilizes a master pattern generated by Additive Manufacturing to create a mold or die. Several techniques are available, the most popular of which is the “soft tooling” technique. Soft tooling technology uses silicone molds to create plastic parts and as sacrificial models for investment casting of metal parts.

Indirect rapid tooling is used for testing and experimentation. For example, when you already have a detailed design and want to test different materials, indirect rapid tooling is a good solution. This is because it allows you to easily build multiple test tools and molds from the same master model.

Steps in Indirect Rapid Machining

Indirect machining is the second form of rapid machining. Indirect machining requires the following steps.

Step 1:Create a model of the master tool or mold using CAD software.

Step 2:Send the file to a machine or printer to make a master mold or tool called a pattern. This master pattern is usually quite durable.

Step 3: Make more molds or tools based on the master pattern. You can make new molds or tools using different materials with different properties. Master patterns can be used for both hard tools (tools made of tough or strong materials) and soft tools (less strong tools). A single master pattern can produce large or small quantities of various tools or molds, which can then be used to create more prototypes.

Advantages of Indirect Rapid Prototyping.

Master patterns are very robust and persistent, and are rarely broken throughout the prototyping process.You may only need one master pattern (unless your design changes).Since all the different tools and molds are based on the same master pattern, there are fewer differences between them.It’s great for experimenting with a variety of materials because you can create the tool or mold that best suits a particular material or prototyping process.

Soft and hard tools can be produced according to customer requirements. Soft tools can be used for simple designs or cost-effective prototyping, while hard tools are suitable for complex designs.

Disadvantages of Indirect Rapid Machining.

Slightly longer production time compared to direct Rapid Machining.It involves an intermediate step, which can lead to higher costs.It may be necessary to use higher quality materials to create a strong and durable master pattern.This is not always a suitable solution if you expect your design to change dramatically during the prototype stage.It is not necessary for simple designs that do not require high dimensional accuracy or precision.

How does rapid prototyping work?

Rapid prototyping is used to quickly create physical parts or components using design tools. The process usually begins with designers and engineers developing a digital design of the product, often using computer-aided design (CAD) software. This digital layout serves as a blueprint for the prototyping process, detailing the dimensions, aesthetics, and functionality of the product.

Once the design is complete, the next step is to translate the design into physical parts or components. Unlike traditional manufacturing methods, which often involve lengthy tooling and setup times, rapid prototyping allows products to be created directly from digital designs. Technologies such as 3D printing, rapid tooling and other advanced prototyping techniques are used to bring the design to life.

Throughout the process, designers and engineers have the flexibility to iterate and refine the product and make adjustments based on feedback and testing. This iterative nature is one of the core benefits of rapid prototyping, ensuring that the final viable product closely aligns with the envisioned design and user needs.

Why Rapid Tooling is importment.

Faster Time to Market:Rapid Tooling can produce molds and tools in less time than traditional methods, reducing the overall time required for product development and manufacturing.

Cost Savings:Rapid tooling can be more cost effective than traditional tooling methods, especially for small production runs or prototypes, as it does not require complex and expensive tooling equipment.

Design Flexibility:With Rapid Tooling, it is easier to incorporate design modifications or improvements during the tooling process, allowing for greater flexibility and faster iterations.

Increased Efficiency: Rapid tooling reduces the lead time between design completion and production, simplifying the manufacturing process and allowing for faster product release.

Customization and Complexity:Rapid tooling techniques, such as additive manufacturing, allow for the creation of complex geometries and custom tooling designs that would be challenging or expensive for traditional methods.