CNC milling services is a machining process that uses computer control and rotating multi-point cutting tools to progressively remove material from a workpiece and produce a custom-designed part or product. The process is suitable for machining a variety of materials, such as metals, plastics, wood, and producing a variety of custom-designed parts and products.What is milling? This is a machining method that uses cutters to shape a workpiece on a table that is usually movable, although some milling machines also have movable cutters. Milling was originally a manual operation performed by workers, but today, most milling is done by CNC milling machines, which utilize computers to oversee the milling process. AN-Prototype CNC milling can provide higher precision, accuracy and productivity.

Table of Contents

ToggleHow does CNC milling work?

Similar to most traditional mechanical CNC machining processes, the AN-Prototype CNC milling process utilizes computer control to operate and steer the machine tools that cut and shape the blank. Additionally, the process follows the same basic production stages as all CNC machining processes, including:

1. Design CAD model

2. Convert CAD model to CNC program

3. Set up the CNC milling machine

4. Perform milling operations

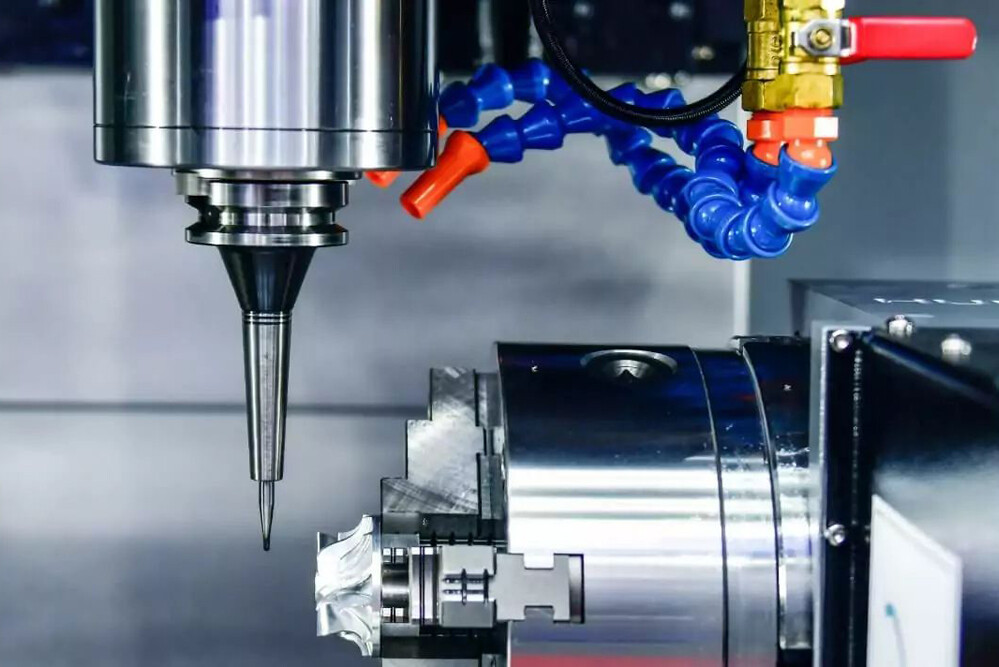

The CNC milling process begins with the creation of a 2D or 3D CAD part design. The complete design is then exported to a CNC-compatible file format and converted via CAM software into a CNC machine program, which directs the machine’s actions and tool movement across the workpiece. Before operators run a CNC program, they prepare the CNC milling machine by securing the workpiece to the machine tool’s work surface (i.e., the table) or workpiece fixture (such as a vise) and mounting the milling tool to the machine tool spindle. The CNC milling process utilizes a horizontal or vertical CNC-powered milling machine – depending on the specifications and requirements of the milling application – and rotating multi-point (i.e., multi-tooth) cutting tools such as milling cutters and drills. When the machine is ready, the operator starts a program through the machine interface, prompting the machine to perform a milling operation.

CNC milling processing steps:

Once the CNC milling process is started, the machine tool begins spinning the cutting tool at speeds of up to thousands of revolutions per minute. Depending on the type of milling machine used and the requirements of the milling application, when the tool cuts into the workpiece, the machine tool will perform one of the following operations to make the necessary cut on the workpiece:

1. Slowly feed the workpiece into the fixed rotating tool

2. Move the tool on the fixed workpiece

3. Relative movement of tools and workpieces

In contrast to manual milling processes, in CNC milling the machine tool typically transports the movable workpiece by rather than by the rotation of the cutting tool. Milling operations that adhere to this convention are called climb milling, while the opposite operation is called conventional milling.

Typically, milling is best used as an auxiliary or finishing process on a machined workpiece to provide definition of or produce features of a part such as holes, slots, and threads. However, the process can also be used to shape stock materials from start to finish. In both cases, the milling process gradually removes material to create the desired shape and part form. First, the tool cuts small pieces (called chips) from the workpiece to form an approximate shape. The workpiece is then milled at a higher rate of progress and with greater precision, resulting in a finished part with its precise features and specifications. Often, the finished part requires several passes to achieve the required accuracy and tolerances. For parts with more complex geometries, once the milling operation is complete and the part is produced to custom designed specifications, the milled part moves into the finishing and post-processing stages of production.

Selection of cutting tools

Since the spindle speed and range of CNC machine tools are much higher than that of ordinary machine tools, and the output power of the spindle is also very large, compared with previous processing methods, the requirements include high precision, high strength, high rigidity, high durability, and high durability. CNC machining tools, including dimensional stability, ease of setup and adjustment, have put forward higher requirements. This requires appropriate tool structure, standardization and concatenation of geometric parameters. CNC tools are one of the prerequisites for improving processing efficiency. Their selection depends on the shape of the component to be processed, the state of the material, the rigidity of the fixture, and the tools selected for the machine tool.

Please consider the following:

1. Select tools based on the cutting performance of parts and materials. For rotating or grinding high-strength steel, titanium, and stainless steel components, indexable carbide tools are recommended for better wear resistance.

2. Select the tool according to the part processing stage. That is to say, in the rough machining stage, AN-Prototype CNC mainly reduces the stiffness by removing finishing machining, with the purpose of selecting more accurate tools. In the semi-finishing process, it mainly ensures the machining accuracy and product quality of the parts, but ensures a higher performance and durability of high-precision tools, tools used in the roughing stage are less precise. 3. Select tools and geometric parameters according to the characteristics of the processing area. If the structure of the part is acceptable, tools with large diameters and small aspect ratios must choose over-center milling tool edges to cut thin-walled and ultra-thin pendulum parts, and must have sufficient centripetal angle to lower the tool and Cutting force of cutting parts. In machining parts of soft materials such as aluminum or copper, choose an end mill with a slightly larger angle, no more than 4 teeth.

CNC Milling Type

General milling:

Also known as face milling or slab milling, is the process of machining flat surfaces using a rotating end mill. The main advantage of ordinary milling is that it can be done on any type of machine, including machine tools (original word order).

Angle milling:

This milling operation places the tool’s axis of rotation at an angle to the workpiece surface, resulting in a design-specified angular cut, such as a groove or dovetail.

Face milling:

It uses an axis of rotation perpendicular to the material surface. A face mill or grinder removes material from the surface of a work piece with its side facing down.

Drilling:

The process of drilling a hole with a rotary drill bit. Drilling is the most common type of CNC milling operation.

Reaming:

The process of enlarging a hole with a rotary reamer. Reaming is often performed after drilling to achieve a better surface finish on the workpiece.

Tapping:

The process of making threads with a rotating tap. Tapping is usually performed after drilling to create internal threads in the workpiece.

What is a CNC milling machine?

CNC milling machine refers to a milling machine controlled by electronic digital signals. It is an automatic processing equipment developed on the basis of general milling machines. It is divided into two categories: without tool magazine and with tool magazine. Among them, CNC milling machine with tool magazine Also called machining center.

CNC milling machine mainly consists of bed, milling head, longitudinal worktable, transverse bed saddle, lifting table, electrical control system, etc. It can complete basic milling, boring, drilling, tapping and automatic work cycles, and can process various complex-shaped cams, templates and mold parts. The bed of the CNC milling machine is fixed on the base, which is used to install and install various components of the machine tool. The console has a color LCD display, machine tool operation buttons, and various switches and indicator lights. The longitudinal worktable and transverse slide plate are installed on the lifting platform, and are driven by the longitudinal feed servo motor, transverse feed servo motor and vertical lifting feed servo motor to complete the feeding of X, Y and Z coordinates. The electrical cabinet is installed behind the bed column, which contains the electrical control part.

3-axis, 4-axis, and 5-axis CNC milling machines

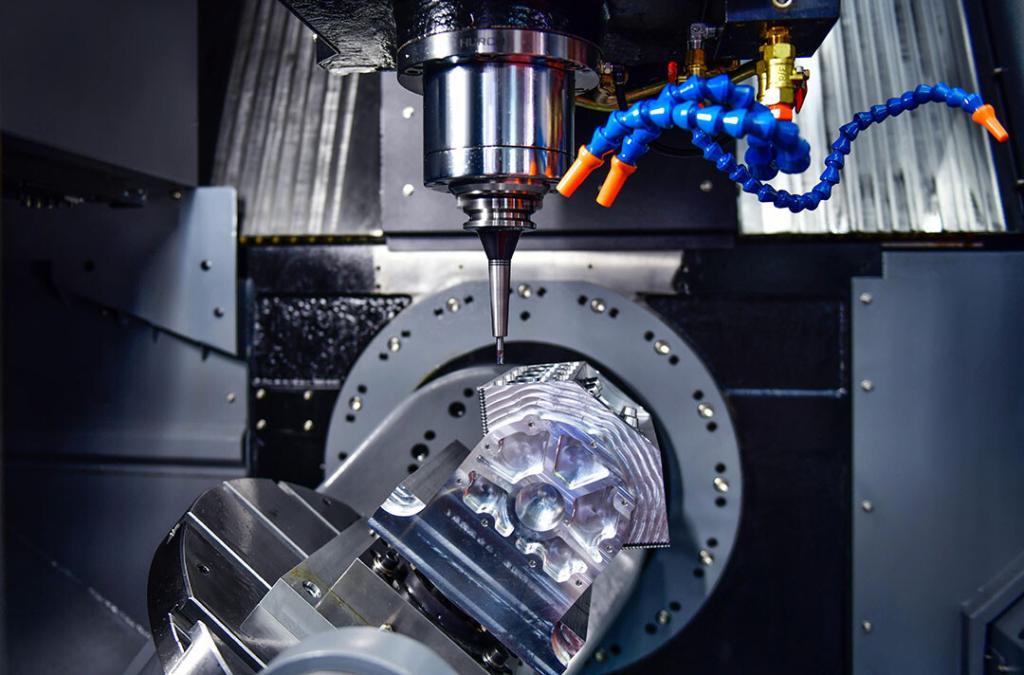

3-axis CNC machining generally refers to three axes of linear motion in different directions, such as up and down, front and back, and left and right.The three-axis machine can only process one surface at a time, which is suitable for processing some disk parts. This is a limitation for many parts that require processing holes or grooves on multiple surfaces.

4-axis CNC machining adds a rotation axis to the 3-axis, usually a 360° rotation on the horizontal plane. But it cannot rotate at high speed and is suitable for processing some box parts.Most 4-axis CNC machines also allow the workpiece to rotate, which is called a b-axis, allowing the machine to function as both a mill and a lathe.If you need to drill holes into the side of a part or the curved surface of a cylinder, 4-axis CNC machining is the way to go. It greatly speeds up the processing process and has high processing accuracy.

5-axis CNC machining is an additional rotation axis on top of the 4-axis, which usually rotates the vertical surface 360°. The five-axis CNC machining can already be fully processed and can achieve one-time clamping, which can reduce clamping costs and reduce product scratches and bruises. .

Common CNC milling materials

6061 aluminum alloy is a high-quality aluminum alloy product produced by heat treatment and pre-stretching process. Although its strength cannot be compared with 2XXX series or 7XXX series, it has many magnesium and silicon alloy properties. 6061 aluminum alloy has excellent processing performance, excellent welding characteristics and electroplating properties, good corrosion resistance, high toughness and no deformation after processing, dense material without defects and easy to polish, easy coloring film, excellent oxidation effect, etc. Features.

Aluminum alloy 7075

7075 aluminum alloy is a cold-processed forged alloy with high strength, much better than mild steel. 7075 is one of the strongest alloys commercially available.

7075 aluminum alloy has general corrosion resistance, good mechanical properties and anodic reaction. Fine grains result in better deep drilling performance, enhanced tool wear resistance and distinctive thread rolling.

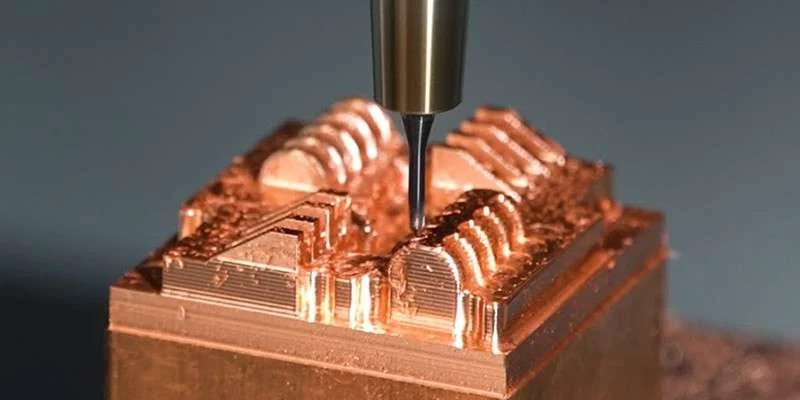

Copper

Pure copper (also known as red copper) is a ductile metal with excellent electrical conductivity and a rose red surface. It is not pure copper, it contains 99.9% copper, and some other elements are added to improve the surface and performance.

Red copper has good electrical conductivity, thermal conductivity, ductility, deep drawability and corrosion resistance. The electrical conductivity and thermal conductivity of red copper are second only to silver, and it is widely used in making electrical and thermal conductive equipment. Copper has good corrosion resistance in the atmosphere, seawater and certain non-oxidizing acids (hydrochloric acid, dilute sulfuric acid), alkali, salt solutions and various organic acids (acetic acid, citric acid) and is used in the chemical industry. It has good weldability and can be made into various semi-finished products and finished products through cold and hot plastic processing. In the 1970s, the output of red copper exceeded the total output of other types of copper alloys

Brass

Brass is a copper-zinc alloy. Brass composed of copper and zinc is called ordinary brass.Red copper has high strength, hardness and strong chemical corrosion resistance. The mechanical properties of cutting processing are also outstanding. Brass has strong wear resistance. Special brass is also called special brass. It has high strength, hardness and strong chemical corrosion resistance. The mechanical properties of cutting processing are also outstanding. Seamless copper pipe drawn from brass, soft and wear-resistant.

45 steel

45 steel is the name in GB, also called “oil steel”. This steel has high strength and good machinability.No. 45 steel has high strength and good machinability. It can obtain certain toughness, plasticity and wear resistance after appropriate heat treatment. The material is conveniently sourced and is suitable for hydrogen welding and argon arc welding.

40Cr steel

40Cr is the standard steel grade of my country’s GB. 40Cr steel is one of the most widely used steels in the machinery manufacturing industry.40Cr steel has good comprehensive mechanical properties, good low-temperature impact toughness and low notch sensitivity. The steel has good hardenability. In addition to quenching and tempering treatment, this steel is also suitable for cyanidation and high-frequency quenching treatment. The cutting performance is better.

Q235 steel

Q235 steel is a type of carbon structural steel, and the Q in its steel number represents yield strength. Normally, the steel is used directly without heat treatment.The yield value of Q235 steel will decrease as the thickness of the material increases. Due to its moderate carbon content, it has good overall properties, and its strength, plasticity and welding properties are well matched, and it has the widest range of uses.

SUS304 steel

SUS304 refers to 304 stainless steel, which has the characteristics of good processing performance and high toughness. Stainless steel 303 can also be processed.SUS304 steel has good corrosion resistance, heat resistance, corrosion resistance, low temperature strength and mechanical properties. It has good hot workability such as stamping and bending, no heat treatment hardening phenomenon, and is non-magnetic.

Application industries

Milling tolerances are large and accuracy is high. Therefore it has a wide range of applications. Here are some of its industrial applications.

Aerospace

Aerospace parts such as: aircraft engine fuselages, impellers and blades require high accuracy and precision, and multi-coordinate high-speed CNC milling machines and vertical machining centers can exactly meet this demand and ensure processing quality and Production efficiency. In addition, materials such as titanium and aluminum are often used in the aerospace industry, which CNC milling is suitable for.

Automobile industry

The automotive field is representative of mass production. Common products are: interior panels, cylinder heads, drive axles, suspension components, exhaust components and gearboxes. Part manufacturing in the automotive field requires increasing efficiency without losing precision. Therefore, it becomes critical to find a company with extensive experience in CNC milling services. AN-Prototype focuses on rapid prototyping and small batch production of plastics and metals.

It has CNC machining, vacuum injection molding, 3D printing, injection molding and other processes. It has obtained ISO9001 and ISO13485 international certifications, and cooperates with Google, ABB, General Medical Maintain long-term cooperative relationships with Fortune 500 companies. The factory is located in Dongguan, Guangdong, with more than 20 engineers. The 5-axis CNC machining center can process parts with complex structures. The CMM three-dimensional coordinate measuring instrument can ensure prototype quality, and a variety of surface treatment processes can meet the needs of prototype production in the automotive, medical, robotics and other industries. Or small batch production needs.

Medical industry

CNC milling machines are also used to produce medical devices such as hip implants and artificial heart valves. Medical components such as prosthetics require precise and unique designs. Therefore, CNC milling is a better method for such parts. Preserve design, be productive and efficient.

Advantages of CNC milling:

AN-Prototype manufactures complex parts. CNC milling is capable of manufacturing highly complex machine parts compared to traditional methods. Modern CNC machine tools are designed to operate on multiple axes. Machine tools and workpieces can interact from different perspectives. The AN-Prototype CNC machining process produces contour details that cannot be achieved with traditional machines.

When CNC milling processes are combined with CAD and other design software, the ability to produce complex machine parts becomes even more powerful. Maximize the transfer of digital designs to tangible objects.AN-Prototype’s fast and efficient CNC milling process. The production process using CNC milling is fast and efficient. Modern milling technology allows CNC milling cutters to be changed automatically during operation. In addition, CNC milling can run multiple axes simultaneously to shorten cycle times.

Conclusion

CNC milling is more economical and reduces waste caused by human error. Cost effectiveness is another factor that businesses can benefit from. This advantage can be easily achieved for most CNC milling operations. One area where this benefit occurs is in material waste. Traditional milling processes are known for high material waste. Miscalculations become common due to excessive human involvement in the machining process. The CNC milling process reduces waste because it automates more precise cuts.

AN-Prototype targets material diversity. Before the advent of CNC milling methods, machine tools were unique depending on the material. CNC milling machines are unique because they can process a variety of materials. This includes metals such as tungsten, silver, gold, stainless steel and copper.Under the composite category, CNC milling can handle hybrid composites, graphite composites, carbon fiber reinforced plastics