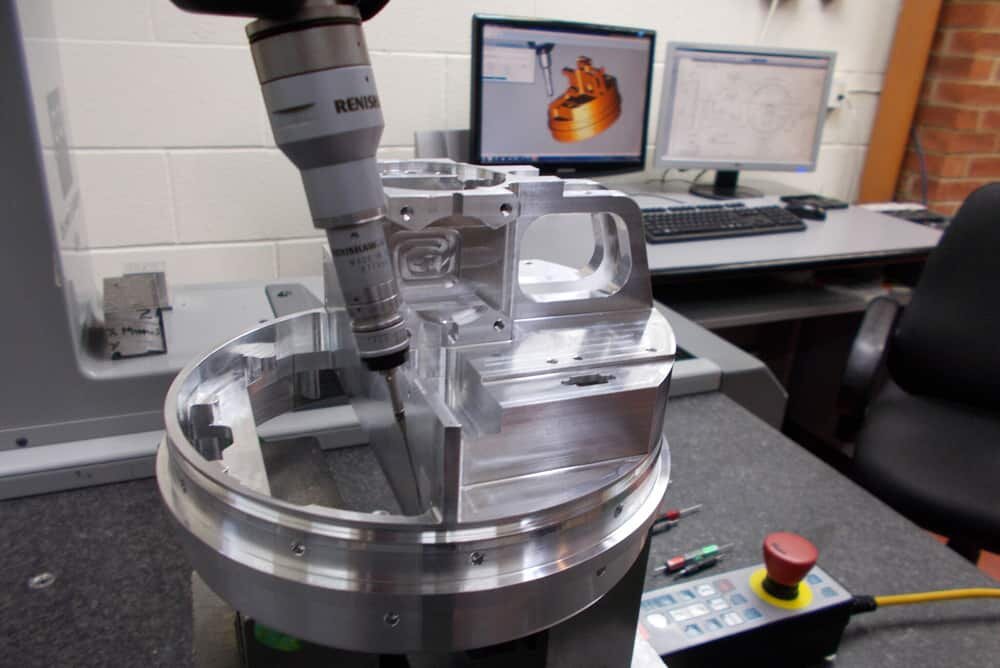

CNC Machining tolerances refer to how close the actual dimensions of a part are to the intended or design dimensions. In other words, tolerance is a measure of how much variation in dimension is acceptable. With CNC machining, parts can be cut to tolerances as tight as ±0.001 inch, and sometimes even better.CNC machining is a crucial process in manufacturing mechanical parts. It is a highly automated process that uses precision tools to create complex, highly accurate parts. However, achieving those tight tolerances can be challenging for manufacturers. In this guide, we’ll provide an overview of CNC machining tolerances, the factors that impact them, and how to design parts to achieve the desired tolerances.

What Are CNC Machining Tolerances?

Tolerance is a measure of the degree of permissible variation from a specified dimension. The concept of tolerances is utilized to ensure that the finished parts are consistent and precise. CNC machines are capable of producing precise parts and components within extremely tight tolerances. Depending on the material and process, tolerances can be as low as a few microns. A single micrometer (µm) is one millionth of a meter.

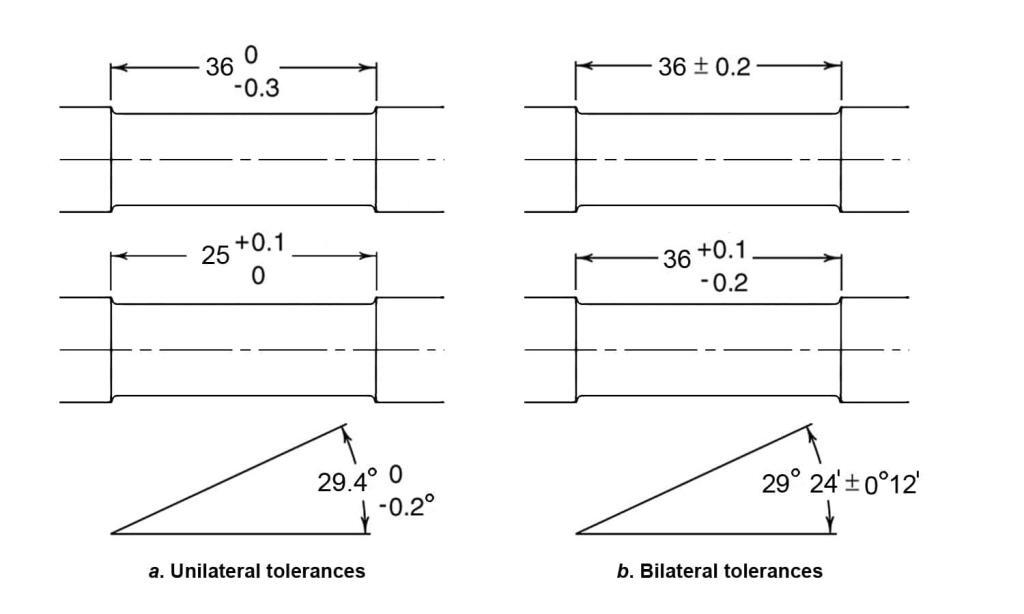

Tolerances are specified in engineering drawings, which serve as a guideline for the manufacturer to produce the part or component with the required tolerance. The tolerance can be specified as a positive or negative deviation from the nominal value. For example, a tolerance of ±0.1 mm means the actual dimension may vary by up to 0.1 mm from the nominal value.

Types Of CNC Machining Tolerances

CNC machining tolerances are crucial to the production of precision parts that meet the required standards and specifications. Mechanical designers should have a clear understanding of the various types of tolerances to ensure that the parts they design will function as intended. The five types of tolerances explored in this post are dimensional, geometric, surface finish, runout and concentricity, and position tolerance. By considering these tolerances, designers can help to minimize manufacturing costs and improve the parts’ efficiency and reliability.

1. Dimensional Tolerances:

These are the most common type of CNC machining tolerances, and they control the size, shape, and position of the machined parts. They ensure that the parts are within the acceptable range of measurement and are functional, fitting, and assembling to other parts. Dimensional tolerances are expressed on engineering drawings as plus or minus values, and they vary depending on the complexity of the part and the level of accuracy required.

2. Geometric Tolerances:

Geometric tolerances are used to specify the allowable shape and orientation deviations of features such as slots, holes, and profiles. They ensure that the parts are within the acceptable range of angles, radii, and distances. Geometric tolerances are expressed using symbols found on the GD&T (Geometric Dimensioning and Tolerancing) chart and are often used to prevent excessive manufacturing costs.

3. Surface Finish Tolerances:

Surface finish tolerances control the smoothness, texture, and roughness of the surface of the machined parts. They ensure that the parts have a consistent and desired surface appearance and allow the parts to function as intended. Surface finish tolerances are expressed using symbols such as Ra (arithmetical average) and Rz (maximum height), and they vary depending on the material, tooling, and application of the part.

4. Runout and Concentricity Tolerances:

Runout and concentricity tolerances are used to specify the allowable deviations of the part’s rotation around its axis and the alignment of the center of the features. They ensure that the parts run smoothly and accurately when in use, reducing vibration and wear. Runout and concentricity tolerances are expressed using symbols found on the GD&T chart and are often used in parts that require precise rotation or positioning.

5. Position Tolerances:

Position tolerances specify the allowable deviations in position between the features of a part to ensure it fits and assembles with other parts within the desired range. They ensure that the parts fit together precisely and prevent any gaps or misalignments that can affect the performance of the finished product. Position tolerances are expressed using symbols found on the GD&T chart and often used in parts that require precise alignment, such as those used in aerospace applications.

Common CNC Machining Tolerances

CNC machining is a broad field that includes milling, turning, surface finishing, and more. CNC machining tolerances vary for each process due to the type of cutting tool used. The following are standard CNC machining tolerances for common processes:

- Router: ± 0.005″ or 0.13 mm

- Lathe: ± 0.005″ or 0.13 mm

- Router (Gasket Cutting Tools): ± 0.030″ or 0.762 mm

- Milling (3-axis): ± 0.005″ or 0.13 mm

- Milling (5-axis): ± 0.005″ or 0.13 mm

- Engraving: ± 0.005″ or 0.13 mm

- Rail Cutting Tolerances: ± 0.030″ or 0.762 mm

- Screw Machining: 0.005″ or 0.13 mm

- Steel Rule Die Cutting: ± 0.015″ or 0.381 mm

- Surface Finish: 125RA

If you compare these values with alternative remanufacturing technologies, you will find that the CNC machining processes involve tighter tolerances.

Importance of Tolerances in CNC Machining

Tolerances play a critical role in CNC machining, ensuring that the final product is functional, safe, and reliable. Tight tolerances are essential in various industries where parts must fit together precisely, and even small variations can lead to disastrous consequences. Therefore, mechanical designers must pay strict attention to tolerances in their designs and ensure manufacturing processes are monitored and controlled to meet their specifications. By maintaining tolerances, efficient production processes, cost savings, and safe, reliable products can be achieved.

1. Meeting Quality Standards

CNC machines are built to produce precision parts that adhere to strict quality standards. To achieve the required precision, it is essential to maintain tolerances during the machining process. Even the slightest deviation from the required measurements can result in parts that do not meet quality specifications. This can lead to a number of issues such as parts failing prematurely or not fitting together properly.

2. Ensuring Compatibility

In many industries, parts need to fit together precisely to function properly. If the tolerances are not tight enough, the parts may not fit together, leading to production errors, reduced functionality, and unsuccessful products. For example, in the aerospace industry, where tolerances can be as tight as a few microns, a single deviation can result in catastrophic damage.

3. Promoting Efficiency

CNC machines are designed for accuracy and speed. By maintaining tolerances, it ensures that the machining process is as efficient as possible. This is because the machine does not have to stop and check parts repeatedly for accuracy, which can slow down the overall process. With the correct tolerances programmed into the machine, the process can continue uninterrupted, resulting in faster production times, increased productivity, and reduced costs.

4. Cost-Effective Manufacturing

Maintaining tolerances in CNC machining can be cost-effective when done correctly. This is because the process requires fewer material and labor resources to produce quality products. When tolerances are not monitored and error rates increase, it can result in wasted resources through scrapped products, production delays, and rework. Additionally, it can result in additional costs associated with reworking and repairing parts.

5. Minimizing Risk

Tight tolerances are crucial when manufacturing parts or systems that pose a safety risk. For example, medical devices, automotive, and aerospace industries require strict tolerance control to minimize the risk of malfunction. By maintaining tolerances within specifications, the risk of equipment failure, injury, and death can be minimized.

Factors in CNC Machining Tolerances

CNC machining tolerances are crucial in ensuring the quality and functionality of the machined parts and components. Factors such as material properties, part geometry and size, cutting parameters and tools, machine capability, and application requirements should be considered when determining the appropriate tolerance levels. By understanding these factors and working closely with the customer, designers, engineers, and manufacturers can optimize the CNC machining process, reduce errors and rework, and deliver high-quality products that meet or exceed the customer’s expectations.

1. Material Type and Properties: One of the most important factors that affect the CNC machining tolerances is the type of material that will be machined. Different materials have different physical properties, such as hardness, ductility, tensile strength, elasticity, and thermal conductivity, which can affect the machining process and the finished part’s accuracy. For example, aluminum is a lightweight, soft, and highly machinable material, while stainless steel is a hard, tough, and more challenging to machine. Therefore, you may need to adjust the tolerances to accommodate the material’s properties.

2. Part Geometry and Size: The complexity and size of the part or component being machined can also impact the CNC machining tolerances. Parts with intricate features, tight corners, or small radii may require finer tolerances to achieve the desired accuracy, while bulkier, more robust parts may tolerate looser tolerances. Moreover, the part’s dimensions and orientation relative to the cutting tool can affect the machining tolerances, especially if the part needs to be refixtured or reoriented during the machining process.

3. Cutting Parameters and Tools: The cutting parameters and tools used in CNC machining can significantly influence the tolerance levels. Factors such as cutting speed, tool diameter, tool wear, surface finish, and tool sharpness can affect the machining tolerances. For instance, slower cutting speeds and smaller tool diameters can improve tolerance accuracy, but may increase cycle time and cost. Additionally, different cutting tools, such as drills, end mills, taps, and reamers, have specific tolerance limits and can affect the part’s dimensional accuracy.

4. Machine Capability and Calibration: The accuracy and repeatability of the CNC machine used for machining can have a considerable impact on the tolerance levels. CNC machines have various precision levels, ranging from standard to high-end models that provide micron-level accuracy. It is essential to use a machine that can maintain tight tolerances consistently over a large production run. However, the machine’s accuracy and performance can degrade over time due to wear and tear, so regular maintenance, calibration, and quality control checks are necessary to ensure the machine’s optimal performance.

5. Application and Customer Requirements: The final factor to consider when determining CNC machining tolerances is the application’s intended use and the customer’s requirements. Some applications may require high precision and tight tolerances, while others may not need such accuracy levels. Moreover, the product’s functional requirements, operating conditions, and environment can influence the tolerance levels. Customer specifications and industry standards may also determine the acceptable tolerance ranges for the product, so it is essential to communicate these requirements clearly with the customer and align them with the production processes.

How Find The Right Tolerance For CNC Machining Parts?

For mechanical designers, finding the right tolerance for their parts is crucial to ensure that their products function correctly. This is because tolerance is the degree of variation allowed in the dimensions or properties of a part. Without the appropriate tolerances, a part may be too loose or too tight, leading to improper functioning, which can adversely affect the overall design or performance of a product.

1. Understand the Function of the Part

Before setting tolerances, it is essential to understand the function of the part. This involves asking questions such as what the part is intended to do, how it will be used, and what environmental factors it will be exposed to. The answers to such questions will give you a good idea of the operating conditions of the part, which will help you determine the appropriate tolerance for its dimensions or properties.

2. Consider the Manufacturing Process

Another factor to keep in mind when setting tolerances is the manufacturing process. Each manufacturing process has its own capabilities and limitations, which may affect the tolerances that can be achieved. For example, a part produced through injection molding may have different tolerances than one produced through CNC machining. Thus, it is essential to consider the manufacturing process when determining the appropriate tolerance for a part.

3. Look at Industry Standards

Another way to determine the right tolerance for your part is by looking at industry standards. There are organizations that provide guidelines on tolerances for various industries. For instance, the International Organization for Standardization (ISO) provides standards for mechanical engineering, which manufacturers can use as a basis for setting tolerances.

4. Conduct Testing and Analysis

Once you have set the tolerance for your part, it is essential to test and analyze it to ensure that it meets the required specifications. Testing and analysis can be done through methods such as dimensional measurements, functional tests, and environmental tests. If the part fails to meet the specifications, adjustments can be made to the tolerance accordingly.

5. Use Tolerance Analysis Software

Lastly, you can use tolerance analysis software to determine the right tolerance for your part. This software allows you to input the dimensions and tolerances of your parts and then runs simulations to evaluate the impact of those tolerances on the overall design. This can save time and reduce the need for physical testing, which can be costly and time-consuming.

6. Work with a Reliable CNC Machining Company

Working with a reliable CNC machining service provider is one of the most effective ways to obtain the required part tolerances. You can discuss your project ideas and specifications with a CNC fabrication expert and determine appropriate tolerances.

Before you can submit a manufacturing request to your rapid prototyping company, you must determine tolerances. Providing this information can lead to significant cost and time savings. What’s more, it’s critical to understand that if you don’t specify specific tolerances, most CNC manufacturers will automatically revert to their standard tolerances.

Although this may seem like an insignificant tolerance deviation, it can affect the fit and function of the final part. For example, if you machine a part with a small hole, even if it is ±0.156 mm, it is not easy to fit its neighbor in it.

Your Trusted CNC Machining Service Expert

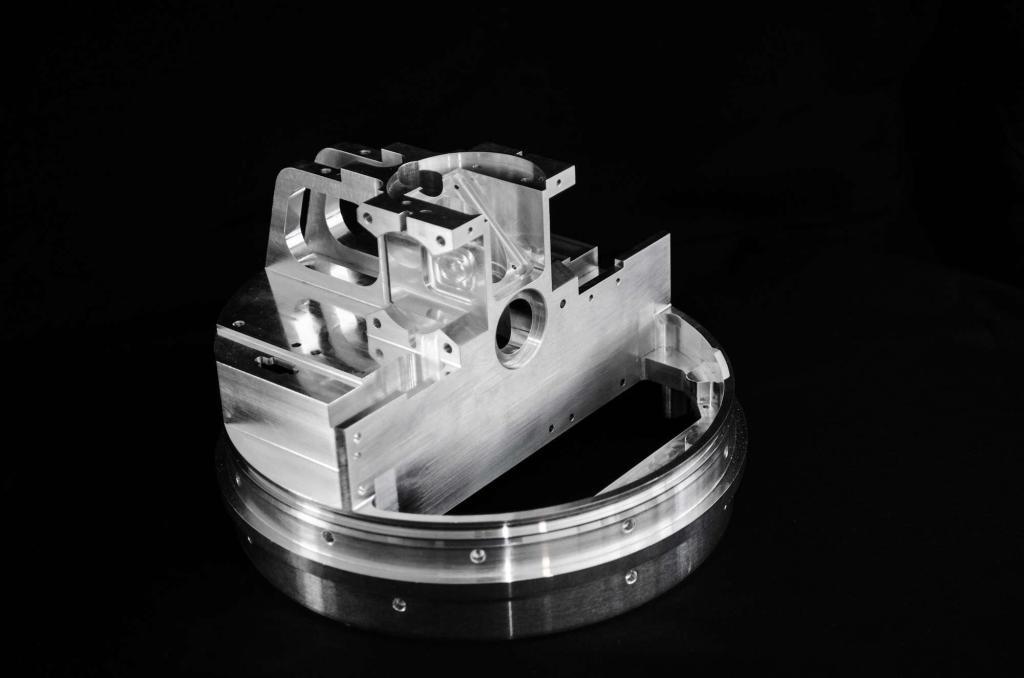

At AN-Prototype, we have invested in the most advanced CNC machines in the industry. Our machines can achieve tighter or looser tolerances, depending on your project requirements. We also have expert machinists and engineers with in-depth knowledge of various machining techniques to ensure that your parts are machined to standard.

Quality is a top priority when it comes to our CNC machining services. We understand that precision is essential for mechanical designers, and our reliable quality inspection system ensures that we deliver machined parts that meet your specifications. We guarantee standard tolerances for CNC machining, and our metal parts adhere to DIN-2768-1-fine, while plastic parts adhere to DIN-2768-1-medium.

When it comes to tolerance, we adhere to a standard tolerance of ±0.005 inches for our CNC machining services. We can also handle the tightest tolerances of approximately ±0.0002 inches (±0.005mm), which is precisely the width of a human hair. With such tight tolerances, you can trust us to deliver machined parts that meet your requirements.

We specialize in CNC machining services, and we have a vast range of manufacturing capabilities to cater to your project needs. We can handle various materials, including metals and plastics, and we use advanced techniques to machine complex geometries, including 5-axis machining. We also offer finishing services to ensure that your machined parts are ready for use.

In conclusion, if you are a mechanical designer looking for an expert CNC machining service, look no further than AN-Prototype. With our state-of-the-art facilities, experienced engineers, and commitment to quality, we deliver machined parts that match your design requirements. Contact us today and let us handle your next project.