CNC machining parts is one of the most popular methods of manufacturing custom parts because the process is highly versatile, repeatable, and reliable—plus, it’s compatible with a wide variety of metal or plastic materials, from wood and plastic to foam , metals, and even ceramics. These CNC machined parts are common across various industries due to their cost-effectiveness for demanding applications. This guide discusses machined CNC machined parts and assemblies, their compatible machining techniques, advantages, and design principles. You’ll also learn about the materials used for CNC machined parts, their applications, and helpful tips for working with a rapid manufacturer of suitable CNC machined parts.

Table of Contents

ToggleWhat are CNC Machining Parts and Assemblies?

CNC (Computer Numerical Control) machining is a subtractive manufacturing process ㅡ which means it uses a CNC machine to remove part of the material from a workpiece to make the part in the desired shape. A computer program (also known as G-code) controls the sequence in which the CNC machine (or workpiece) moves relative to each other to create the desired part. Standard CNC machines include multi-axis CNC mills, lathes (or lathes) and milling machines. Although all CNC machine types rely on computer instructions to perform subtractive manufacturing, they operate in slightly different modes. CNC manufacturing operations include CNC drilling, milling, turning, and grinding. Plus, you can create CNC parts from any metal, plastic, or any other material that can be cut without severe degradation.

Rapid manufacturers and machinists use different CNC machining processes to produce parts for different purposes. The following are standard manufacturing techniques and methods used to achieve different results:

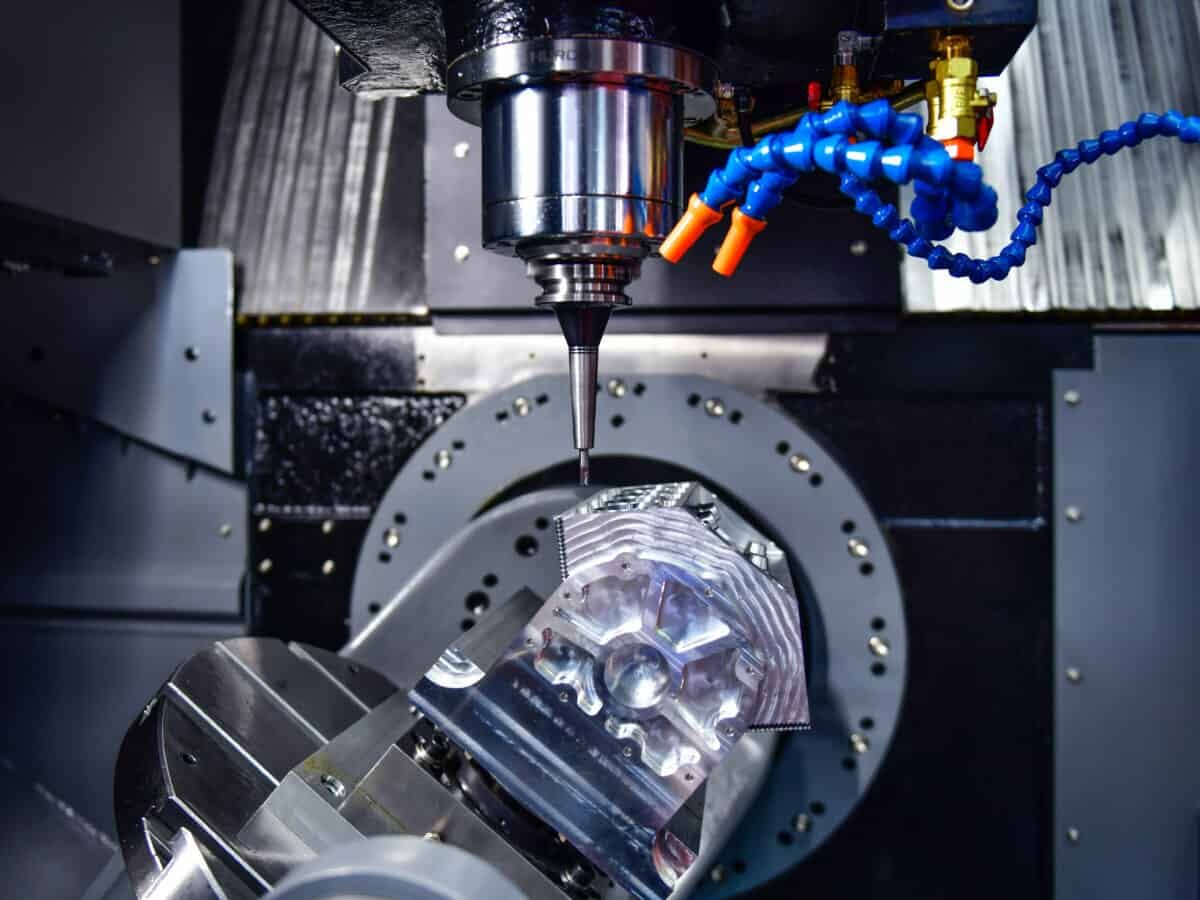

CNC Milling

CNC Milling: This subtractive manufacturing process involves the use of a CNC milling machine to remove material from a workpiece to form a CNC part with contours or surfaces. Common types of milling operations include CNC milling, face milling and end milling. These machining processes involve the use of various milling machines and cutting tools.

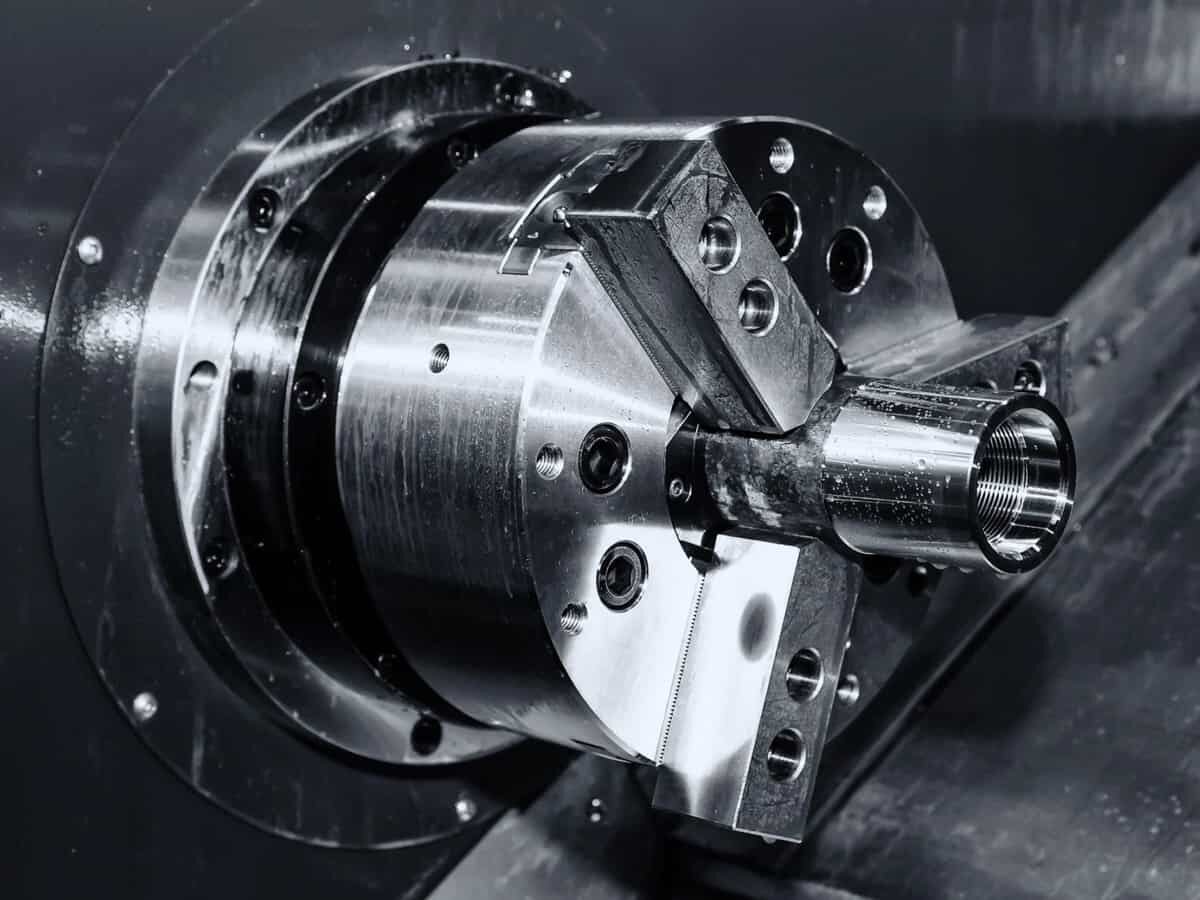

CNC Turning

CNC Turning: This metal cutting process involves rotating a workpiece while simultaneously feeding a cutting tool to remove material and machine cylindrical or conical shaped parts. CNC turning is a reliable method for machining threads, shafts, and complex features on the outer surface of machined parts.

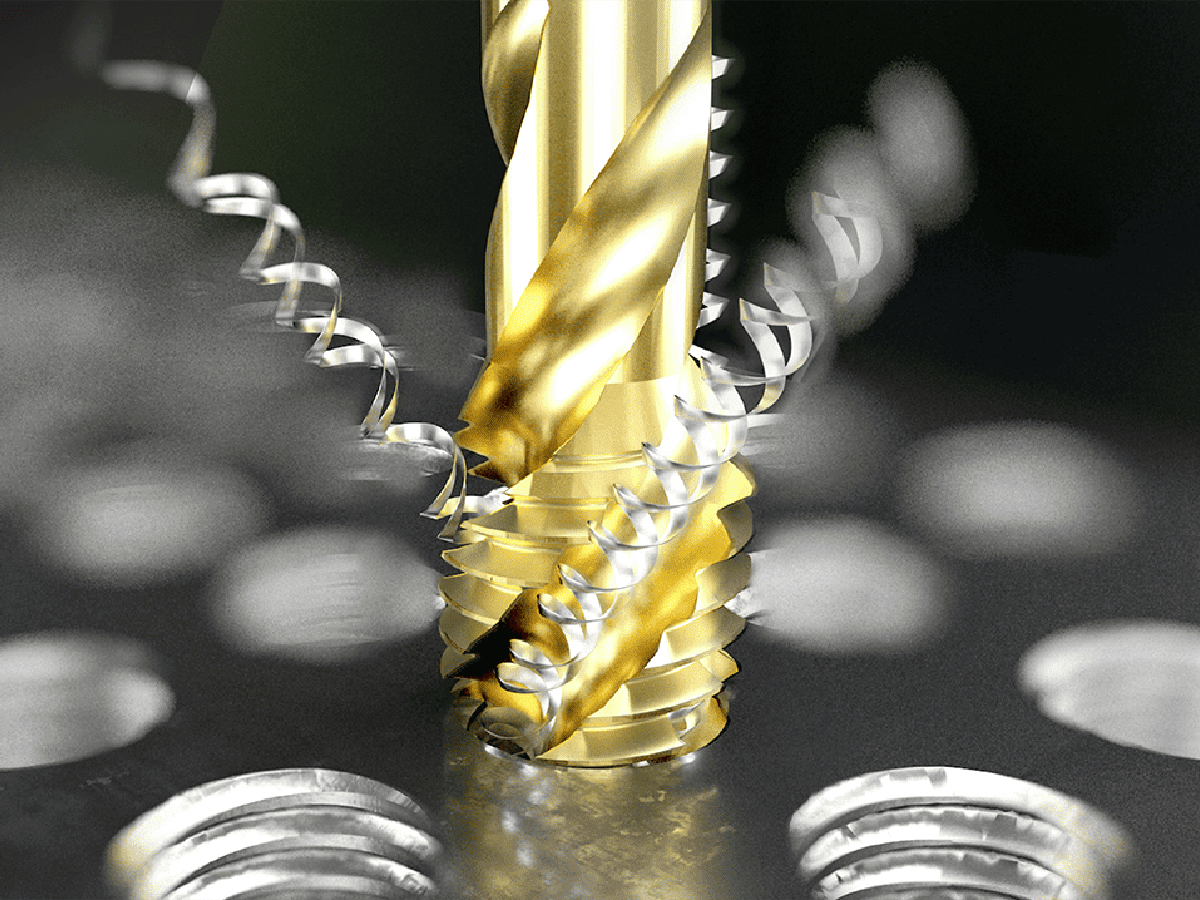

CNC Drilling

CNC drilling is a process that utilizes a rotating cutting tool to create a circular hole in a stationary workpiece. This is an important process commonly used in industry to machine holes of different sizes and depths in CNC machined parts, machine screws or bolts for assembly purposes.

CNC Tapping

CNC tapping is a common and useful process for creating threads on parts. It creates threads in holes that must be drilled with a tap and chamfered at the end in order to drive a screw or bolt into the hole. CNC tapping efficiently and accurately cuts internal threads to precise specifications.

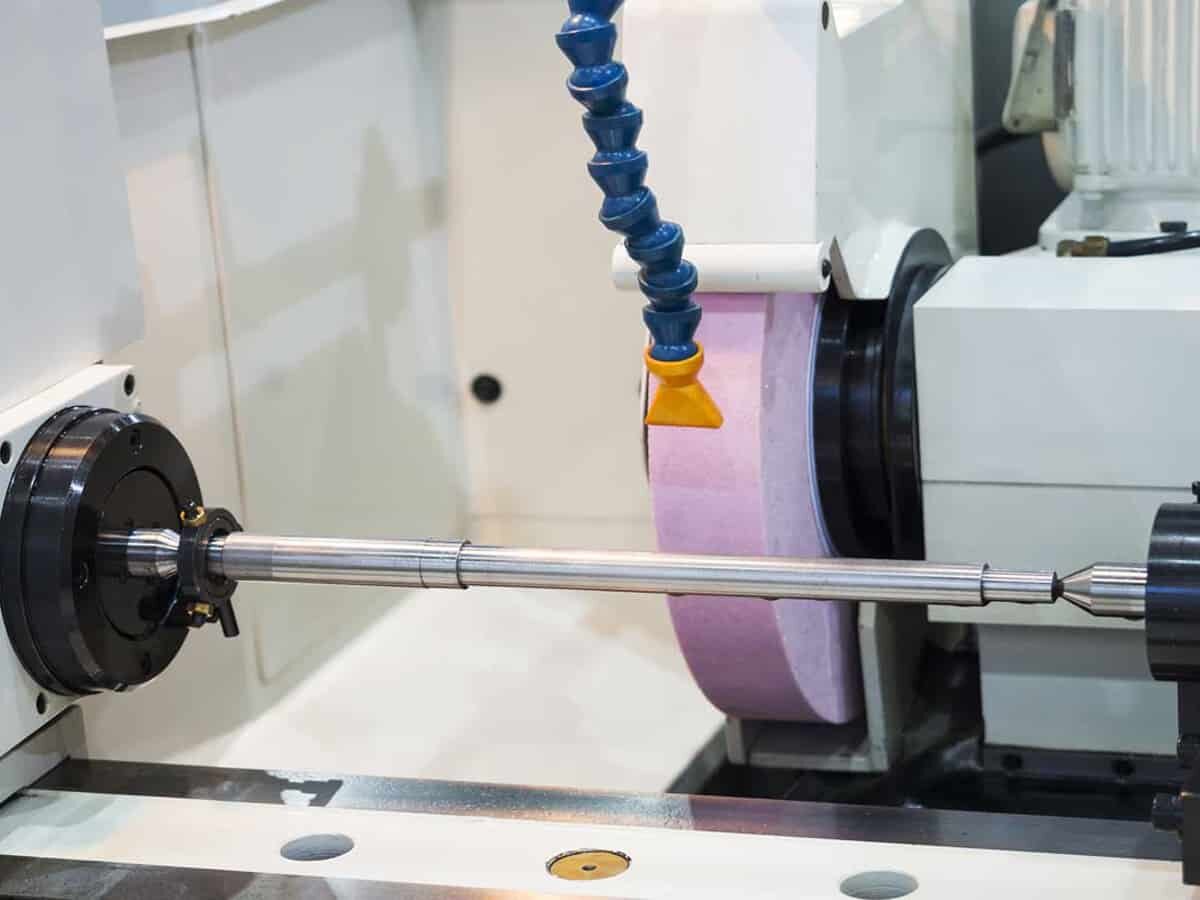

Precision Grinding

Grinding involves cutting material from the surface of a CNC-machined part using a grinding wheel to create a high-precision and smoother surface.

Laser Cutting

Laser cutting involves blowing, vaporizing or melting material with a high-powered laser beam to make precise cuts in the workpiece. It is a technique suitable for cutting plastic, metal and other materials.

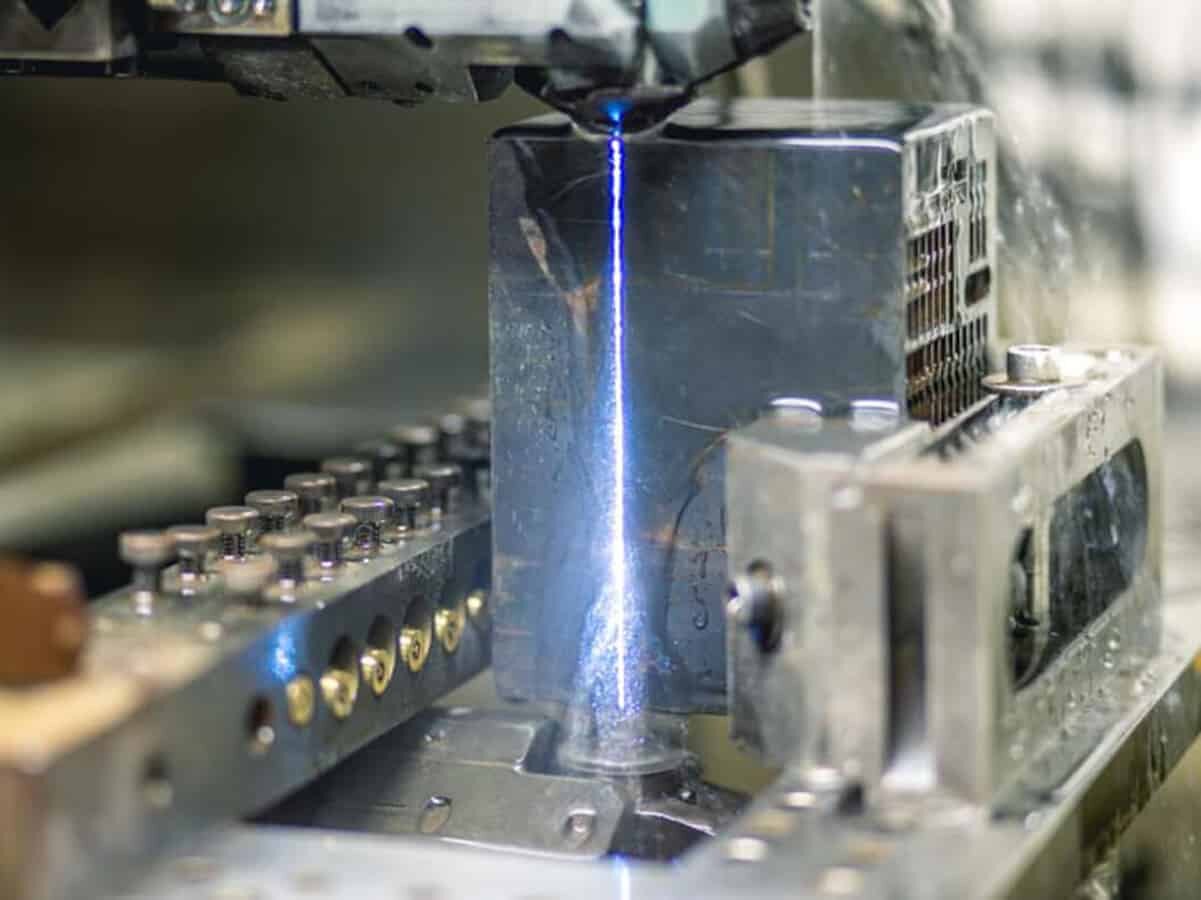

EDM Machining

EDM refers to the use of electric discharge to cut material from workpieces, which can meet the high precision required for the manufacture of complex-shaped parts.

Wire Machining

WIRE EDM machining, a category of EDM, is a non-contact subtractive manufacturing process that uses electrically charged thin wires and a dielectric fluid to cut metal parts into different shapes.

Advantages of CNC machining parts

CNC parts are more beneficial than 3D printed and injection molded parts. AN-Prototype summarizes the typical advantages of CNC machining parts:

Sophisticated Prototype

CNC machining technology provides parts and prototypes with complex designs and intricate features. These machined prototypes feature highly desirable precision features at an affordable price. Because CNC machining is digital and faster, it’s easier to quickly duplicate parts. Thus, you can carry out the necessary tests and evaluations on the prototype before making the final product.

In addition, CNC machining is compatible with multiple materials, allowing you to order different metal alloys or engineering plastic prototypes and parts to check the performance after considering all relevant factors to get the best prototypes and parts.

No MOQ

One of the significant advantages of CNC machining parts is that there is no minimum order quantity required. You can easily CNC machine parts, making low-volume or one-off parts cost-effective. Therefore, you can easily order as many machined parts as you need. CNC machining is virtually unique in producing quality parts with no minimum order quantity requirements or risk of excess inventory. Therefore, it is very suitable for prototyping, low-volume manufacturing.

CNC machined parts are stronger

Machinists create CNC machined parts from a solid material called a blank. These blanks are usually produced by extrusion or casting processes. Therefore, CNC machined parts are stronger than other parts such as 3D printed parts. Also, molded parts are not as strong as machined parts because molded parts typically have thin walls with limited mechanical properties.

Design Freedom

CNC machining of parts allows for unhindered design freedom to achieve different design features such as complex shapes and sizes. These CNC parts often have fine and detailed features. CNC machined parts offer complex design capabilities that can meet the needs of a variety of applications.

Faster Leading Time

CNC machining makes metal or plastic parts faster than other manufacturing processes such as injection molding, vacuum casting, etc. CNC machining is not a labor-intensive process, but an automation of the machine, so the production process is very efficient. Some CNC machining centers are equipped with fast linear guideways, and the one-step nature of the machining speed and automated machining process shortens lead times for machined parts.

Surface Finishing of CNC Machined Parts

CNC machining is a highly efficient way of producing a variety of metal or plastic parts. However, achieving the desired surface finish for these parts can pose a challenge. Vibrations, tool wear, and material characteristics can all affect surface quality, leading to roughness, scratches, or blemishes. Fortunately, various surface treatment techniques can help improve the appearance, durability, and functionality of CNC machined parts.

As-Machined

CNC machining produces parts with an "as-machined" or "as-milled" finish upon completion of the manufacturing process. These parts exhibit small but visible tool marks and blemishes, with an average surface roughness of approximately 3.2 μm. As-machined parts offer tight dimensional tolerances and cost-effectiveness, as post-processing is not required. This finish is a suitable choice for those prioritizing dimensional integrity over aesthetics. However, parts with as-machined finishes do not provide significant protection. Their roughness and lack of a protective coating make them susceptible to nicking, scuffing, and scratching.

Anodizing

Anodizing is an electrochemical process that converts the surface layer of a metal, such as aluminum or titanium, into a durable and corrosion-resistant oxide coating. The anodized layer can also be dyed in various colors, creating a decorative or functional effect. Anodizing can improve the hardness, wear resistance, and lubricity of the part surface, and can be done in different thicknesses and finishes. It requires careful cleaning, masking, and rinsing steps to ensure consistent coating quality.

Sandblasting

This process involves blasting the surface of the CNC machined part with abrasive material, such as sand or glass beads, at high pressure. Sandblasting can remove burrs, rust, and imperfections, and create a uniform matte or glossy finish. It can also enhance adhesion of paint or coatings. Sandblasting can be performed manually or automatically with a CNC-controlled machine. However, it may damage delicate parts or produce a rough surface if not done properly.

Plating

Plating is a process of depositing a metal or alloy coating on the surface of a substrate. It can improve the appearance, conductivity, wear resistance, or corrosion resistance of the part. Common plating materials include nickel, chrome, zinc, and copper, and they come in different types of finishes, such as bright, matte, or satin. Plating requires precise control of the plating solution composition, temperature, and current density to achieve the desired thickness and adhesion.

Painting

Painting is a conventional method for adding color, texture, and protection to a CNC machined part surface. It involves applying a liquid or powder coating, such as epoxy, polyester, or acrylic, using spray, brush, or electrostatic methods. Painting can provide a wide range of colors, patterns, and gloss levels, and can resist abrasion, chemicals, and weathering. However, painting requires proper surface preparation, curing, and ventilation to avoid defects, such as runs, sags, or fisheyes.

Polishing

Polishing is a mechanical or chemical process of smoothing and shining the surface of a CNC machined part. It can remove a layer of material from the surface, reducing roughness, scratches, and other defects, and revealing a mirror-like finish. Polishing can be done with abrasives, such as sandpaper, buffing compounds, or diamond pastes, or with chemicals, such as acids or electrochemical solutions. Polishing can enhance the aesthetic appeal of the part and improve its surface hardness, wear resistance, or optical properties.

Surface treatment plays a crucial role in optimizing the quality and functionality of CNC machined parts. By choosing the right treatment method and parameters, manufacturers can achieve the desired appearance, durability, and performance of their products. The above-mentioned surface finishing techniques are just a few examples of what’s available. Depending on the material, shape, and function of the part, other methods such as grinding, honing, or laser etching may also be useful. At the same time, it’s important to balance the benefits and costs of surface treatment, as some methods may add extra time, cost, or environmental impact to the production. Ultimately, the end user’s needs and preferences should dictate the extent and type of surface finishing applied to CNC machined parts.

8 DFM for CNC Machining Parts

1. Material Selection: The choice of material plays a critical role in the CNC machining process. Different materials have varying properties that affect how they behave while being machined. Aluminium, for example, is a soft and ductile material that is easy to cut and shape, while stainless steel is tougher and requires more force to machine. Choosing the right material for your part and its intended use is essential for achieving the desired performance and durability.

2. Part Geometry and Complexity: The geometry and complexity of a part also impact the CNC machining process. Parts with intricate designs and tight tolerances require more precise and delicate machining techniques to ensure accuracy and consistency. Simpler designs, on the other hand, can be machined faster and with less risk of errors or defects. Therefore, it is important to balance the desired design with the practicality and capabilities of the CNC machine and the machining team.

3. Feature Size and Shape: The size and shape of the features on a part should also be considered when designing for CNC machining. If the features are too small or too thin, they may break or deform during machining, resulting in scrap or rework. If the features are too large or too complex, they may require multiple machining passes or tool changes, increasing the time and cost of production. Therefore, it is important to optimize the feature size and shape for the desired function and manufacturability.

4. Draft and Undercuts: Draft and undercuts are angles or contours on a part that allow it to be easily removed from the mold or the machining tool. Without proper draft and undercuts, the part may become stuck or damaged, leading to increased waste and downtime. Therefore, it is important to include draft and undercuts in the design and ensure that they are feasible for the CNC machining process.

5. Surface Finish Requirements: The surface finish of a part can affect its appearance, texture, and performance. CNC machining can achieve various surface finishes, from rough to mirror-like, depending on the tooling and settings used. However, achieving a specific surface finish may require additional time and cost, especially for intricate or large parts. Therefore, it is important to discuss the surface finish requirements with the machining team and select the appropriate tools and techniques to achieve them.

6. Assembly and Tolerance Stack-Up: If the CNC-machined part is intended to be assembled with other components, the tolerance stack-up between the parts must be considered during the design phase. Tolerance stack-up refers to the accumulation of small variations in dimensions and positioning that can cause misalignment or interference between parts. Therefore, it is important to apply the correct tolerances and ensure that the parts will fit together correctly during assembly.

7. Tooling and Fixturing: CNC machining requires specific tooling and fixtures to hold the part securely and accurately while being machined. The choice and quality of the tooling and fixtures can affect the precision, speed, and quality of the machining process. Therefore, it is important to choose the right tooling and fixtures for the part and ensure that they are properly maintained and calibrated.

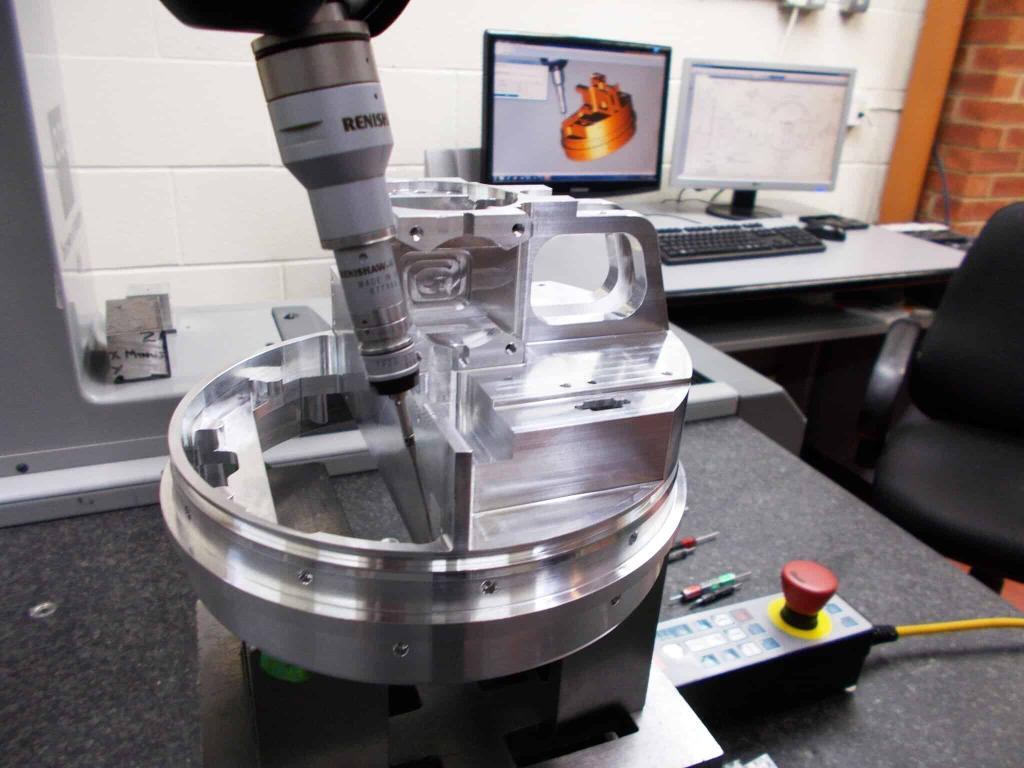

8. Testing and Validation: After the CNC machining process is complete, the part must be tested and validated to ensure that it meets the desired specifications and requirements. This may involve various types of inspection, measurement, and testing methods, such as visual inspection, dimensional measurement, hardness testing, or functional testing. Failure to test and validate the part can lead to quality issues, safety problems, or customer dissatisfaction.

Designing for CNC machining requires careful considerations to optimize the process and ensure the desired results. By following the top eight design for manufacturing considerations, you can enhance the manufacturability and performance of your CNC-machined parts and avoid common pitfalls.

Materials For Machined Part

Through CNC machining, it has become easier and more efficient to produce parts with complex shapes and designs. One important factor that contributes to the success of CNC machining is the choice of materials. Choosing the right material for your parts is critical to ensure quality, durability, and attainment of the desired final product.

Metals, with their unique combination of strength and ductility, make them ideal for parts that require strength and durability. Some of the popular metals used in CNC machining include Aluminum, Copper, Brass, and Steel. Aluminum, for instance, is known for its high strength-to-weight ratio, making it an excellent material for lightweight parts. Steel, on the other hand, is known for its exceptional strength and hardness, perfect for parts where strength and durability are paramount.

Common metal materials for CNC machining parts: Titanium, Bronze, Brass, Copper, Aluminum, Stainless Steel (303、304、316、17-4, Inconel 625 & 718), Zinc, Magnesium.

Plastics are also popular materials in CNC machining. They are lightweight, durable, and have good machining properties. Acrylic, Polycarbonate, Nylon, and Polyethylene are among the popular plastic materials used in CNC machining. Polycarbonate, for instance, is a strong and durable material that makes it ideal for parts that require resistance to impacts.

Common plastic materials for CNC machining parts: ABS, PC, POM, ABS+PC, PP, PMMA (Acrylic), PS, PEEK, HDPE, DHPE, PPS, Teflon, PAGF30, PCGF30.

3. Composites

Composites are materials made by combining two or more materials to create a material with unique properties. Carbon fiber is an example of composite material popular in CNC machining. Carbon fiber is known for its light weight and incredible strength, making it perfect for high-performance parts that require strength and durability.

4. Ceramics

Ceramics, well known for their hardness and ability to withstand extreme temperatures, are popular materials in CNC machining. Silicon Carbide, Zirconia, and Alumina are some of the ceramics used in CNC machining. Alumina, for instance, is known for its hardness, high strength, and resistance to wear and corrosion, making it perfect for parts that require strength and durability.

5. Wood

CNC machining is not limited to metals, plastics, composites, or ceramics; wood can also be machined using this technology. Wood has a unique appearance and appeals to the eye, making it a popular choice for many parts, especially those that require aesthetic appeal. Some of the common woods used in CNC machining include Oak, Walnut, Maple, and Birch.

Choosing the right material for your CNC machining parts is critical to the success of your desired final product. The above-discussed materials, including metals, plastics, composites, ceramics, and wood, are just some of the materials you can choose from. Ensure you understand the properties of each material and select one that best meets your needs.

Tolerances of CNC machined parts

Tolerance is the allowable deviation or variation from a standard or an accepted range. In CNC machining, the tolerance is the accepted deviation or variation from the target or desired dimension that is acceptable to the customer. Simply put, it is the degree of variation from the indicated or desired dimensions that are still acceptable.

Factors Affecting CNC Tolerances

Several factors affect the tolerance levels in CNC machining, some of which include the material being machined, machine type and age, tooling and programming technique used. While the tolerances of different materials and machines vary, it is essential to note that a good operator knows how to make adjustments and ensure proper settings for each job to achieve a specific tolerance.

Importance of Tolerances in CNC Machining

Measuring and maintaining tolerances are integral to ensure that a product will work correctly and that every part is interchangeable with the others. Therefore, the knowledge of the tolerances in CNC machining is vital for ensuring that the parts produced are reliable and meet the necessary specifications. Understanding tolerance levels can also help in determining the cost-effectiveness of different CNC machining processes.

| Tolerance Lever | Overall Dimension Range | ||||||

|---|---|---|---|---|---|---|---|

| Specifications | <<3 & >0.5 | <<6 & >3 | <<30 & >6 | <<120 & >30 | <<400 & >120 | <<1000 & >400 | <<2000 & >1000 |

| F | ±0.05 | ±0.05 | ±0.1 | ±0.15 | ±0.2 | ±0.3 | ±0.5 |

| M | ±0.1 | ±0.1 | ±0.2 | ±0.3 | ±0.5 | ±0.8 | ±1.2 |

| C | ±0.2 | ±0.3 | ±0.5 | ±0.8 | ±1.2 | ±2 | ±3 |

| V | – | ±0.5 | ±1 | ±1.5 | ±2.5 | ±4 | ±6 |

Methods used to Ensure CNC Tolerance

To ensure the tightest tolerances in CNC machining, machinists often use a range of tools and techniques, including using high-quality machine tools, regular machine maintenance, inspection, and validation of CAD models, as well as active monitoring of the production process.

Understanding tolerances in CNC machining is crucial in ensuring the quality, functionality, and cost-effectiveness of a product. While tight tolerances are ideal, it is also essential to achieve a balance between tolerance levels and production speed to maximize the yield without sacrificing quality. With the right knowledge and expertise, a customer can receive precisely what they require, making CNC machining the perfect solution for precision manufacturing.

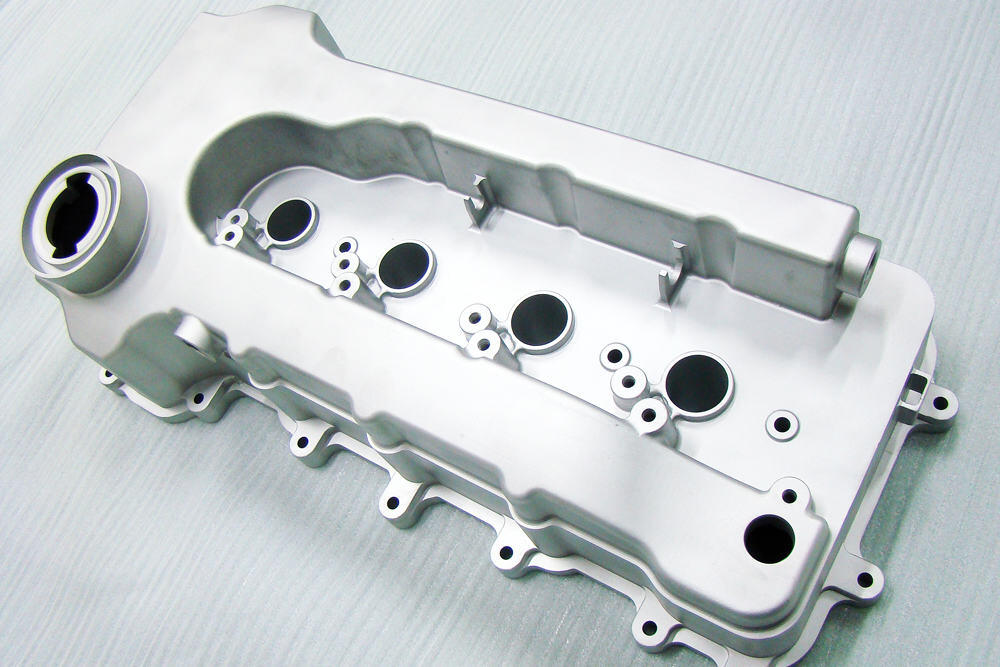

Application of CNC machining parts

CNC machined parts and components are compatible with various applications in every industry since they have become indispensable. Typical machined components used in different applications include valve bodies, ball joints, rollers, housings, gears, fasteners, brackets, etc. Below are common industries that use machined parts:

The aerospace industry requires CNC machining parts to be manufactured accurately and with high precision. CNC machining parts ensure that the components used in aircraft and spacecraft are reliable and functional enough for use in a harsh environment. The parts are used in the production of aerospace engines, turbines and air ducts, hydraulic systems and flight control systems, and many more.

The medical industry is another sector where precision and accuracy are crucial. CNC machining parts are used to create medical devices and equipment that are safe to use, reliable, and of high quality. CNC machining parts are used in manufacturing artificial joints, orthotic devices, surgical tools, prosthetics, and many more. It’s safe to say that the medical industry heavily relies on CNC machining parts.

CNC machining parts have revolutionized the automotive industry. The parts find their use in the production of automotive engine parts, suspension and steering components, transmission parts, brake components, chassis, and many more. CNC machining enables the automobile industry to produce quality components in mass quantities, enhancing the production efficiency of car manufacturing.

4. Defense and Military Industry:

The Defense and Military industry also relies on CNC machining parts to produce robust components for use on land, sea, and air. CNC machining is used in creating parts for aircraft, missiles, guns, tanks, and many more. The use of CNC machining parts in the Defense and Military industry ensures that the equipment remains reliable even in challenging conditions.

5. Electronics Industry:

The electronics industry heavily relies on CNC machining parts to manufacture and produce electronic devices like computers, cellphones, and other devices with circuit boards. The machining parts assist in the production of electronic parts because they need to be precise so the circuits can function as intended.

From the aerospace industry to the electronics industry, CNC machining parts have become a valuable resource in the manufacturing industry. With the ability to produce parts with high precision and accuracy, the use of CNC machining has revolutionized the manufacturing industry, enabling manufacturers to produce quality components in mass quantities. Understanding the different applications of CNC machining parts provides insight into the role it plays in the manufacturing process, making the production of reliable products efficient and accurate.

Choose a trustworthy CNC machining expert

You need a reliable machining partner to outsource your CNC machining needs for low or high volume machined parts or prototypes. Working with a third-party CNC machining service provider is often more beneficial than an in-house solution due to factory space and the expertise required to operate the machine tools and equipment.

While choosing a reliable machining partner for your machined parts can be quite challenging, here are some helpful factors and practices to consider:

1. Check the Expert’s Reputation: Before selecting any CNC machining expert, you should inquire about their reputation in the market. Read online reviews and check the expert’s ratings on business directories. Additionally, you can contact their previous customers to learn more about the expert’s capabilities and experience. A reliable expert will have high ratings and positive reviews from their past clients.

2. Verify Their Experience and Expertise: CNC machining is a complex process that requires knowledge and skill. Therefore, it is essential to look for an expert that has experience and expertise in the field. You can ask the professional about their experience and training programs done. Similarly, ask them about the level of experience they have with the specific requirements of your project.

3. Inspect Their Facility and Equipment: A reliable CNC machining expert must have a well-maintained facility and the latest equipment. CNC machining requires precision tools and equipment, so it is crucial to make sure that the expert uses the newest technology. Inspect the expert’s facility and equipment to ensure that they have the technology and tools to fulfil your project requirements.

4. Verify Communication and Customer Service: Your CNC machining project’s success relies on the quality of communication and customer service you receive from the expert. Therefore, it is vital to opt for a provider with excellent customer service and communication abilities. Make sure that the expert is transparent and informative about their manufacturing processes and updates you on the project’s progress throughout.

5. Check Price and Delivery Time Estimates: Finally, you should consider the price and delivery time estimates proposed by the expert. It is important to choose an expert that offers reasonable pricing for their services and can complete your project within the estimated delivery time. If the price sounds too good to be true, it probably is. Moreover, an experienced expert should be able to estimate the delivery time accurately and stick to the schedule.

6. Certifications: Although certifications will not tell you the machining company’s scope of abilities, ISO certifications are helpful because they are a remarkable guideline for identifying capable machining companies.

AN-Prototype is a trusted partner in CNC machining services in China for your rapid prototyping and CNC machining parts needs. We provide high quality parts and prototypes at competitive prices and shorter lead times. Our efficient quality control system helps your products to go to market faster. We have many years of experience producing machined parts for different industries.

Our machine shop has cutting-edge machinery and a quality management system capable of producing high-quality CNC parts with high precision and accuracy. Contact us today and let us help you with your machined parts!