AN-Prototype, an ISO 9001:2015 certified and ISO 13485:2016 certified rapid manufacturing company, is an expert in CNC machined medical parts manufacturing. Manufacturing of medical parts requires tighter tolerances and unique materials. AN-Prototype’s top-of-the-line CNC machining equipment, knowledgeable machinists, and strict quality control have made us well-known in the field of precision medical machining.

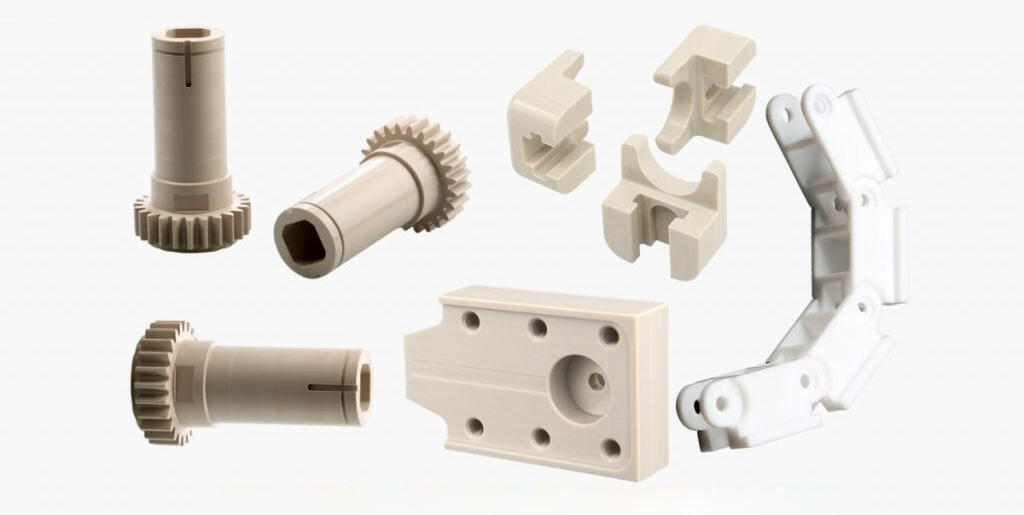

Injection molding, additive manufacturing (3D printing) and CNC machining are common processes for manufacturing medical components. Among them, CNC machining is one of the best options for manufacturing medical prototypes due to its high degree of customization, tight tolerances, excellent surface finish and certified material selection. The versatility of CNC machining and its compatibility with a variety of processes and materials make it useful in the medical manufacturing industry. CNC machining of medical prototypes is faster and more cost-effective.

This article discusses why CNC machining is ideal for your medical components. AN-Prototype will also take an in-depth look at the various materials used for medical CNC machining to help you choose a more suitable material.

Table of Contents

ToggleCNC machining capabilities for medical parts

AN-Prototype’s extensive portfolio of CNC machining services includes CNC Swiss precision machining, CNC turning and CNC milling.

CNC Swiss Machining

CNC Swiss precision machining services are particularly useful for medical components and are ideal for high-volume manufacturing of long, thin, tiny parts with tolerances within ±0.0001 inches. Advanced CNC Swiss machining equipment including up to 9-axis lathes enables rapid manufacturers to manufacture extremely complex medical parts quickly and accurately.

CNC Turning and Milling

Rapid Maker’s CNC turning and milling centers quickly and reproducibly produce complex parts with superior craftsmanship. CNC mills and lathes are capable of manufacturing complex plastic or metal parts with tight tolerances.

Advantages of CNC machining medical parts

1. CNC machining manufactures complex custom medical parts with incredible precision and tight tolerances, ensuring the integrity of medical instruments and devices.

2.CNC machining uses computer-aided design files and advanced software to guide CNC machines and manipulate tools, allowing for greater precision and eliminating the risk of human error.

3. CNC processing is compatible with a variety of materials, including medical-grade engineering plastics (PEEK\PTFE), stainless steel, aluminum, titanium, and other metal materials.

4. CNC machining process is highly repeatable, allowing rapid manufacturers to easily create consistent medical parts that meet strict quality standards.

Materials for CNC machining medical parts

CNC machining of medical parts must not only consider tolerance, ductility, and tension requirements, but also the sterilization requirements of medical parts. Therefore, it is crucial to select only the right CNC machining material that meets functional and quality specifications. Let’s take a look at the common materials used for CNC machining medical parts.

Metal For CNC Machining Medical Parts

Metal materials for CNC machined medical devices must be corrosion-resistant, sterilizable, and easy to clean. Among them, stainless steel is a common metal material for manufacturing medical parts because of its excellent mechanical properties such as being resistant to rust, having low and non-magnetic properties, and being easy to CNC machining. In addition, stainless steel can be further processed, such as heat treatment to make it harder. Titanium and aluminum are also increasingly popular among manufacturers of medical devices, such as handheld, wearable, and implantable medical devices, due to their excellent strength-to-weight ratio.

Aluminum | Aluminum is a strong and lightweight metal material with good corrosion resistance. Additionally, aluminum can be easily anodized to improve its mechanical properties and corrosion resistance. However, aluminum is not suitable for manufacturing equipment that comes into contact with human tissue, but it can be ideal for support equipment such as wheelchairs, orthopedic braces, and IV poles. |

Stainless Steel | Stainless steel is an excellent choice for a variety of applications due to its biocompatibility, high durability, strength, and corrosion resistance. In addition, stainless steel parts can be polished to give them a fine surface for easier cleaning. Applications for stainless steel medical parts include hip joints, forceps, hemostats, and other surgical instruments that are a good choice. |

Copper | Copper has excellent antibacterial and antiviral properties. Therefore, it is ideal for frequently touched surfaces such as monitor switches and buttons. Some rapid manufacturers also use it in some dental implants. |

Titanium | Titanium offers high strength, durability, and biocompatibility, making it a good alternative to stainless steel. Therefore, it is an excellent choice for making bone substitutes, prosthetics, and skeletal supports. |

Magnesium | Magnesium has an excellent strength-to-weight ratio and is also a safe metal. Because of its tendency to safely biodegrade, magnesium is mostly used in bone graft substitutes and heart stents. |

Plastic For CNC Machining Medical Parts

Plastics and composite materials for manufacturing medical devices should have low water absorption (moisture resistance), easy sterilization, low friction, and better temperature resistance. Additionally, medical plastic materials should all be sterilizable using autoclave, gamma ray, or EtO (ethylene oxide) methods. One of the great advantages of plastic as a material for medical devices is that it does not interfere with medical diagnostic results because it is not magnetic.

Name | Plastic For CNC Machining Parts |

Delrin | Delrin is a high-strength, rigid, and dimensionally stable thermoplastic material used in medical applications. It is also chemically resistant and has a low coefficient of friction, making it ideal for use in CNC-machined medical devices that require durability and precision. Examples include orthopedic implants, forceps, scalpels, inhalers, and simple medical device components. |

Acrylic | Acrylic is known for its impact resistance and optical clarity. It is used in the manufacture of many machined medical parts such as contact lenses, orthopedic implants, dentures, microscopes and lasers, and protective shields. |

Polycarbonate(PC) | Polycarbonate is well known for CNC machining in the medical industry due to its high strength, impact resistance, and optical clarity. Some of its applications include medical device tubing and connectors, goggles and shields, respiratory masks, surgical instrument handles, and medical device housings. |

PEEK | PEEK is an engineering thermoplastic widely recognized for its exceptional strength and exceptional high performance. It is highly chemical resistant, making it ideal for use on medical parts exposed to harsh chemicals. Applications include temporary contact products, ventilator tubes, surgical clips, X-ray machines, and prosthetics. |

Polytetrafluoroethylene (Teflon) | Teflon is a medical-grade thermoplastic known for its high heat resistance and good dimensional stability. It is a reliable choice for applications requiring repeated steam sterilization and equipment requiring high precision and reliability. Examples include catheters, implantable devices, prosthetics, wound dressings, etc. |

Polypropylene (PP) | PP has high chemical resistance, allowing it to be used in equipment that is continuously disinfected. It also exhibits good dimensional stability when manufacturing precision parts, including test tubes and pipettes, medical packaging components, inhalers and nebulizers, and single-use medical devices such as syringes and IV sets. |

Ultra-high molecular weight polyethylene | Ultra-high molecular weight polyethylene is widely accepted in the medical field due to its biocompatibility, high strength, and wear resistance. Medical products produced from this plastic include orthopedic implants, scalpels and razors, catheters, splints, trauma plates, and more. |

Nylon | Nylon is used in medical applications due to its toughness, strength, and toughness. It is ideal for components such as sutures, catheters, forceps, clamps, implants, and dental equipment. |

Applications of CNC machining medical parts

Applications for CNC machining range from surgical tools to medical devices to medical implants and more.

#1 Hip Replacement and Knee Implants

Body implants, such as knee implants and hip replacements, require a high level of precision and accuracy in CNC machining technology. A slight error in the CNC manufacturing process can have a significant impact on a patient’s life and well-being. Swiss CNC machining helps to precisely manufacture patient-specific parts while achieving tolerances as precise as 2μm. Body implants are made from biocompatible materials such as PEEK and titanium.

#2 Surgical Tools

CNC machining plays an important role in machining surgical tools. Complex surgical procedures, ranging from simple scalpels to complex robotic arms for minimally invasive surgery, require precise tolerances. CNC machining can achieve complex geometries and tight tolerances, making it ideal for producing complex surgical tool designs.

#3 Electronic Medical Equipment

Many medical testing devices, such as MRI scanners, heart rate monitors, and X-ray machines, come with hundreds or thousands of parts, including switches, buttons, and levers, as well as electronic housings. These medical testing devices do not need to come into contact with the internal tissues of the human body and therefore do not need to be biocompatible. Relatively speaking, CNC processing of parts for medical testing equipment is relatively easy.

#4 Custom Prosthetics

CNC machining offers the possibility to personalize prosthetics, creating customized devices based on each patient’s unique physiological characteristics. 3D scanners are used to establish CAD modeling, and CNC machining is used to manufacture prostheses with highly complex details and high-precision dimensions based on set drawings to ensure optimal functionality, comfort, and safety for patients.

#5 Small Orthopedic Hardware

Patients’ damaged bones and joints often require orthopedic devices such as plates, screws, and rods. Given that they are implanted inside the human body, these small orthopedic hardware must be of the highest precision and quality. CNC Swiss machining plays a vital role in the manufacturing of these orthopedic instruments. CNC technology enables high-precision machining of small parts with complex geometries in a variety of biocompatible materials, including titanium and stainless steel.

#6 Medical Device Prototypes

Before mass production of medical devices, it is critical to create prototypes to test and validate their functionality. CNC machining of medical prototypes is one of the quick and cost-effective solutions to ensure their safety, effectiveness, and compliance with FDA regulatory specifications. In addition, CNC processing can also manufacture medical prototypes in small batches to capture the market as quickly as possible.

#7 Dental Tools and Implants

CNC machining is a very efficient process for manufacturing custom dental tools and implants. CNC machine precision dental parts such as drills, scalers, probes and tweezers. Dental parts require exceptional durability to withstand sterilization while ensuring patient safety. CNC manufacturing offers repeatability and strict quality control, ensuring every tool meets exacting standards.

Choose a Factory for CNC Machining Medical Parts

When you design a medical implant, instrument or device and prepare to outsource manufacturing to a CNC machining shop, there are two key factors you must consider.

ISO 9001 and ISO 13485 certification are required

You need to ensure that your CNC machining shop is ISO 9001 and ISO 13485 certified. The ISO 9001-certified CNC machining shop strictly adheres to legal and regulatory requirements to ensure high-quality CNC machining services. ISO 13485 is an international healthcare system standard that provides quality management system specifications for medical device or instrument manufacturers.

Find an experienced CNC machining expert

You want to make sure you work with a machine shop that has experienced machinists as well as CNC quality control experts. AN-Prototype is the world’s leading provider of medical CNC machining services. With nearly two decades of CNC manufacturing experience, we have a reputation for manufacturing high-quality medical components utilizing state-of-the-art in-house CNC technology. We have an experienced team of CNC technicians and quality control experts, and our factory is ISO 9001 and ISO 13485 certified. Tell us about your project today and let us help you manufacture medical precision parts exactly to your specifications.