In machinery and circuits, heat sinks are the most neglected components. However, this is not the case when designing hardware as heat sinks play a very important role. Almost all technologies including cpu, diodes and transistors generate heat, which can degrade thermal performance and make operation inefficient.

To overcome the challenge of heat dissipation, different types of heatsinks are designed to work with different components and keep them operating at optimum temperatures.With the rapid advancement of technology (especially nanotechnology) and to make things as compact and efficient as possible, proper heat sink design has become a check and balance factor in manufacturing electronic products. Therefore, this article will discuss the details and design considerations of heat sinks.

Table of Contents

ToggleWhat is a Heat Sink?

A heat sink is a widely used method of cooling parts or assemblies that may become hot while in use. Many types of electronic and mechanical devices or machinery use heat sinks to help them dissipate the heat they generate.Heat sinks are vital for any machine that uses wires, electronics, microchips or anything else that naturally generates heat. In the modern world, that pretty much covers everything.

If you’re familiar with the term ‘heat sink’ then you might associate it with laptops, desktop computers, cpu’s or manufacturing. Obviously, the size of such components varies greatly, but they all rely on heat sinks for thermal regulation.In laptops or PCs and other electronics, they do this by circulating heat from the central processor or microchip. Machines in mass production factories and warehouses often use them to redirect hot air from electrical components and wires.

Types Of Heat Sinks

The first step in determining a heat sink design is to determine the type of configuration. There are two popular types of heat sink.

Passive Heat Sinks

Passive Heat Sinks are the traditional choice; they use natural airflow. Natural convection builds up over the Heat Sinks and moves heat away from the components. They are cheaper to operate and do not require additional electricity.

Active Heat Sinks

Active Heat Sinks are more efficient and powerful, but they require forced convection and use air or fluid to make heat transfer possible. They are easily recognisable because they use motorised devices such as fans near the Heat Sinks.

Choosing any type of Heat Sinks can lead to design changes. For example, an active heat sinks that relies on a fan requires a smaller surface area and lighter materials to dissipate the same amount of heat as a passive conductor.

Copper Heat Sinks

Copper is often used as the core material for a wide range of heat sinks designs due to its impressive heat transfer qualities. It is an excellent conductor of heat and helps to quickly and efficiently carry heat away from the device or circuit you are trying to cool. On the downside, copper heat sinks are often more expensive (up to three times heavier) than popular alternatives such as aluminium.

Aluminium Heat Sinks

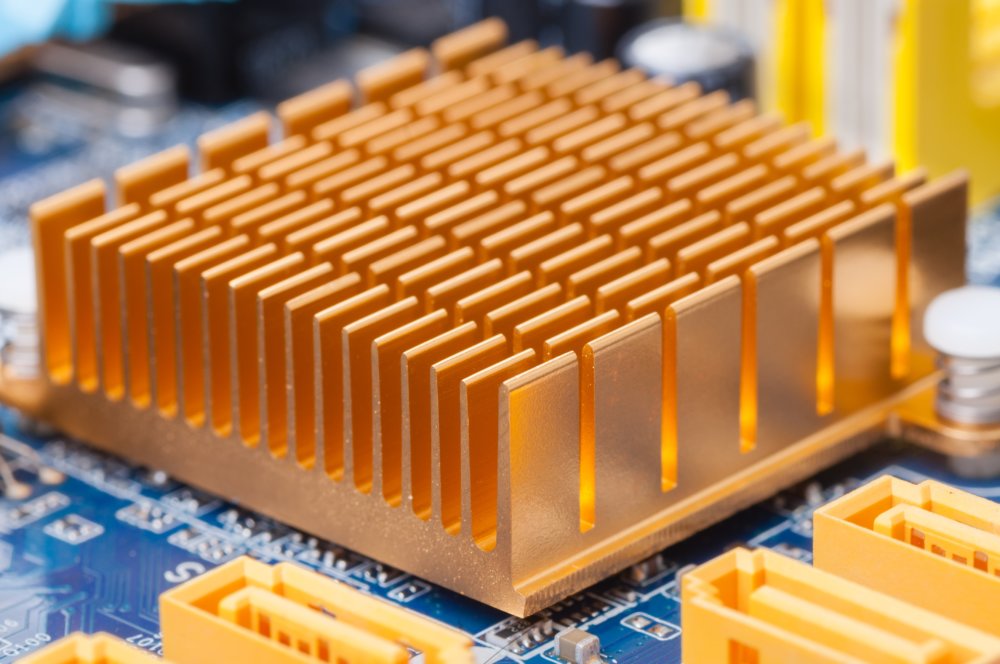

Although aluminium does not conduct heat as efficiently as copper, it is fairly light and cheaper. When used in thin sheets (extruded aluminium) it can also be a more structurally robust metal, as is the case with most copper and aluminium heat sinks constructions. A design feature of many aluminium heat sinks is to allow heat to rise through a number of thin metal fins – explained in more detail in the following section.

Some types of heat sinks, such as bonded fins, can be made from both copper and aluminium. It is not uncommon for one metal to be used for the base or contact plate (usually copper) and the other for the fins.

Finned Heat Sinks

Finned heat sinks are made from a solid block of metal that is feathered or cut into a number of very thin plates that extend from a central block. This design gives a heat sinks with fins a larger surface area. It can more efficiently transfer heat away from any component to which the cooler is attached.

There are several potential processes that can be used when designing and manufacturing a heat sink. Today, the most common are probably forging or die-casting moulds, or CNC machining or milling. Die-cast finned heat sinks are more common in cheaper, high-volume sales, while CNC milled finned heat sinks typically produce a more expensive but higher quality product that tends to ship in lower quantities.

Fixed Heat Sinks

A heat sink with pins can be called either simply a pin heat sink or a pin fin cooler. In fact, it is simply an alternative design to the more common flat fin design outlined above. In pinned construction, the core block consists of a set of pins or rods that extend upward or outward from its base. The pins themselves can be cylindrical, oval or square.

A pinned heat sink is typically calculated to have a larger total surface area than a finned heat sink. However, they don’t necessarily give you a significant performance improvement in many everyday applications, and they are usually not as widely used as fin models.

Heat Sink Materials

Heat sinks are usually made from aluminium alloys or copper and the material is usually determined by the application, thermal strength, production method and budget.

Aluminium heat sinks are usually made from aluminium 1050 (very thermally conductive but low strength) or aluminium 6060, 6061 or 6063 (less conductive but with better mechanical properties). The most affordable heat sinks are usually made from aluminium alloys.

Copper heat sinks have excellent thermal conductivity – it is twice as conductive as aluminium – as well as corrosion resistance, antimicrobial properties and other desirable properties. This makes copper heat sinks a premium option; however, not only is copper more expensive than aluminium alloys, but it’s also often more difficult to shape.

Graphite

Graphite and other carbon materials have thermal properties close to those of copper, but are significantly lighter. They are used in applications where weight is a critical factor.

Diamond

Diamond has the best thermal conductivity of any material, but its high cost and complexity of manufacture limits its use in specialist high-end applications such as semiconductor cooling.

Heat Sink Manufacturing Types

What turns a simple piece of metal into these complex cooling devices? Let’s take a look at six manufacturing processes for heat sink.

Extruded

Extrusion is a continuous process in which aluminium or other heat sink material is heated and forced through a die with a specific cross-sectional profile. The material is rendered in continuous lengths with the desired shape and can then be cut to the required size. Its high production speed and cost-effectiveness make it suitable for high volume production. Consistent material properties are maintained throughout the extrusion process.

Die Casting

During the die casting process, molten metal, such as aluminium or zinc, is injected into a steel die (mould) under high pressure. This active process ensures that the molten metal completely fills the mould cavity. As the metal is actively forced into the cavity, it solidifies quickly and conforms to the shape of the mould. The high pressure maintained ensures that every mould detail is precisely filled, resulting in a heat sink with complex features and smooth surfaces.

Stamping Fin

Stamping involves the use of dies and punches to cut and shape sheet metal into a desired shape. This process produces heat sinks with specific dimensions and patterns. Stamping is suitable for creating repetitive patterns such as fins, is cost-effective for medium to high volumes, and has relatively fast production speeds.

Computer Numerical Control (CNC) machining is the process by which a computer tells a machine exactly how to carve a heat sink from a block of metal. This process allows for the creation of complex geometric shapes and intricate details. Advanced machining technology offers several advantages, including high accuracy and precision, the ability to customize designs, and suitability for small to medium volume production.

Metal Skiving

Skiving is a precision cutting process that transforms a solid block of metal (usually aluminium or copper) into a heat sink with a series of thin, evenly spaced fins. The process begins with a rectangular block of metal, which is then machined to produce the desired finned surface. Fin thicknesses range from 0.25 to 0.8 mm, allowing for high thermal efficiencies in light weight fins.

Metal Forging

Forging involves shaping metal by applying compressive force through tools such as dies, hammers or presses. The process improves the grain organisation and mechanical properties of the material. Forging is the choice for making heat sink because it produces strong single-piece structures with excellent heat transfer and low resistance, perfect for demanding cooling tasks.

Comparing CNC Machining and Aluminum Extrusion for Heat Sink

Despite the fact that there are so many ways to machine heat sink, the most common and widely used are CNC and extrusion.

Benefits of CNC machining heat sink

CNC machining offers several advantages for the production of aluminium heat sink:

Precision and accuracy

CNC machining allows the creation of highly accurate and precise heat sink designs with tight tolerances and complex geometries. This allows the production of heat sink with optimum thermal performance, tailored to the specific requirements of the application.

Material versatility

CNC machining allows for the machining of a wide variety of aluminium alloys, each with their own unique properties and characteristics. This flexibility allows manufacturers to select the optimum heat sink material based on factors such as thermal conductivity, corrosion resistance and weight.

Reduced Lead Times

CNC machining processes can produce aluminium heat sink relatively quickly, especially when compared to other manufacturing methods. This helps to reduce lead times and increase overall productivity.

Customization

CNC machining allows for highly customized heat sink designs, enabling manufacturers to offer bespoke solutions to their customers. This is particularly beneficial for niche applications or specialised industries where off-the-shelf solutions may not be suitable.

Benefits of aluminium extruded heat sink

Aluminium extrusion also offers several key benefits for heat sink manufacturing.

Efficient production

Extrusion is an inherently efficient manufacturing process as it creates continuous aluminium profiles with minimal waste. This can result in cost savings, especially for mass production runs.

Design Flexibility

Although not as versatile in terms of design complexity as CNC machining, aluminium extrusion still allows for a wide range of heat sink shapes and sizes. This is advantageous for manufacturers seeking to strike a balance between design flexibility and production efficiency.

Consistent quality

The extrusion process produces aluminium heat sink with consistent quality and uniform material properties. This helps to ensure that the heat sink works reliably and efficiently throughout its lifetime.

Scalability

Aluminium extrusion is highly scalable, making it ideal for manufacturers who need to produce large quantities of heat sink. The extrusion process can be easily scaled up or down to accommodate different production requirements without significant impact on cost or lead times.

CNC Machined Heat Sinks | Aluminum Extrusion Heat Sinks | |

Precision and Accuracy | High precision and accuracy with tight tolerances and complex geometries for optimal thermal performance. | While precise, they might not reach the complexity that CNC machining can provide. |

Material Versatility | Can work with a wide range of aluminum alloys, allowing for optimal material selection based on thermal conductivity, corrosion resistance, and weight. | Typically limited to specific aluminum alloys suitable for the extrusion process. |

Production Speed | Relatively quick production, reducing lead times. | The very efficient production process, is suitable for large-scale production runs. |

Customization | The high degree of customization, allows for bespoke solutions. | Some degree of design flexibility, but not as high as CNC machining. Ideal for standard shapes and sizes. |

Consistency and Quality | Consistent quality, dependent on the precision of the CNC machine and program. | Consistent quality with uniform material properties, due to the nature of the extrusion process. |

Scalability | Scalable, but setup and programming time can increase for different designs. | Highly scalable, ideal for large volumes, with minimal impact on cost or lead times when changing production volume. |

Both CNC machining and aluminium extrusion have their own advantages and disadvantages when it comes to manufacturing efficiencies.CNC machining can produce highly complex and customised heat sinks, but the process can be more time-consuming and expensive, especially for large production runs. Aluminium extrusion, on the other hand, is a more efficient and cost-effective method of producing large quantities of heat sinks, although the process may not be suitable for highly complex or specialised designs.

Ultimately, the choice between CNC machining and aluminium extrusion for the manufacture of heat sinks will depend on factors such as the complexity of the design, the volume of production required and the specific thermal management requirements of the application.

How to choose the right heat sink

When you ask yourself, “What type of heat sink should I buy?” the answer almost always depends on your specific setup and cooling needs. The first step in understanding how to choose a heat sink is to determine some basic details about your intended application.

Key considerations for optimal heat sink selection include.

What kind of power consumption the component in question will use. This is often referred to as the TDP (Thermal Design Power, or Thermal Design Profile).TDP is often used as a basic indication of the power consumption of a component, especially cpu (processor) and gpu (video card).The TDP rating specifies the maximum amount of heat in watts that a component can use. This is often a good indicator of how hot a particular component has the potential to get under load.Ideally, how cool the component needs to stay for optimal performance.

How much space is available to install a cooler, radiator or radiator – they come in a variety of sizes from tiny modular radiators to much larger installations.Which type of radiator design or layout will provide the best thermal performance for your system specification.

Whether you need an active or passive radiator?

How much you are willing to spend on a cooler?

Conclusion

In summary, heat sinks play a vital role in managing the temperature levels of electronic devices, providing an efficient and cost-effective solution for thermal management. By understanding the materials, design considerations and performance factors associated with heat sinks, you can make informed decisions to optimise the cooling solution for your application. At AN PROTOTYPE, we provide high-quality heat sinks tailored to your needs, ensuring reliable performance and longevity for your electronic systems.