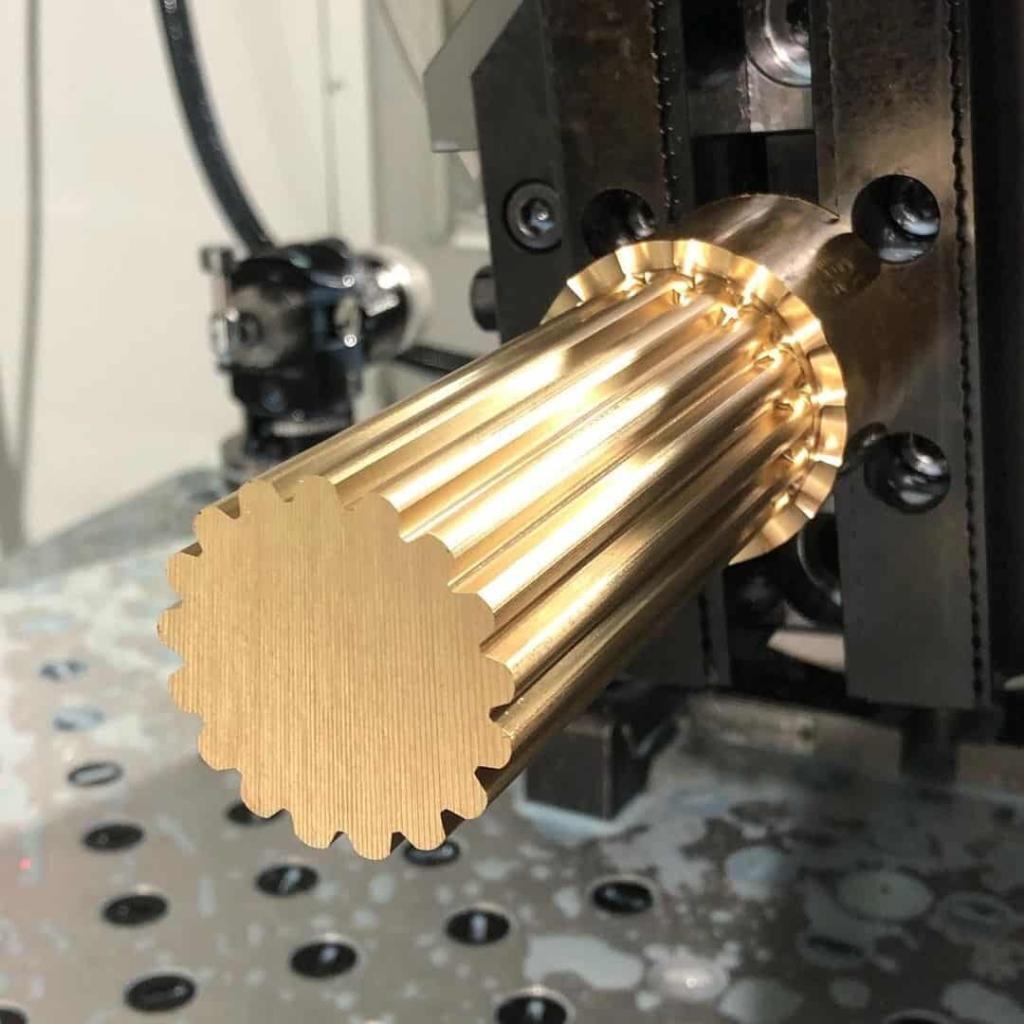

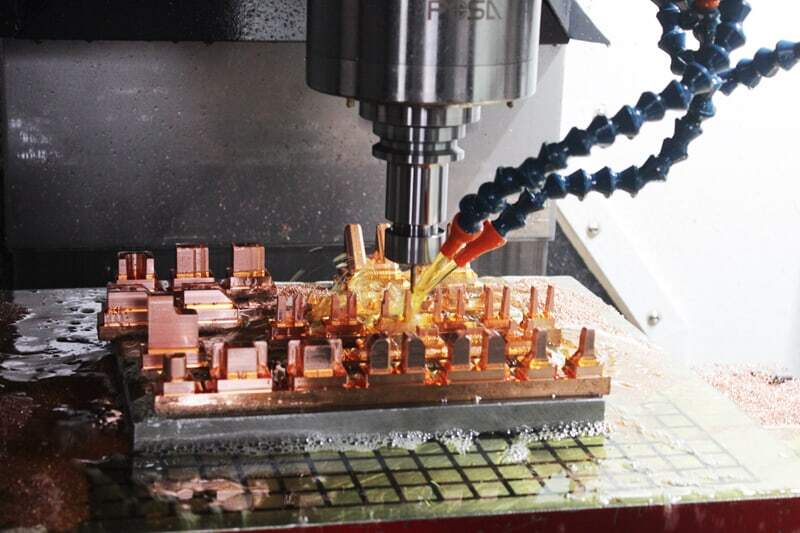

CNC machining copper is one of the most efficient processes for manufacturing copper parts for various industries. Copper has high corrosion resistance, electrical conductivity, thermal conductivity, strength, and ductility, so industries such as automotive, aerospace, and medical require a large number of CNC copper parts. In terms of CNC processing, pure copper has poor machinability due to its high plasticity and toughness. Alloying elements such as zinc, tin, aluminum, silicon and nickel with copper can change the composition of the material and can greatly improve machinability. CNC machining copper operations include: milling, turning, slotting, drilling, tapping, counterboring, chamfering, threading, knurling, brazing, grooving, trimming, and nickel plating.

Table of Contents

ToggleWhat are the properties of copper?

Copper is an extremely versatile metal, making it one of the best options for CNC machining custom parts. Copper has several useful properties.

Extremely good electrical and thermal conductivity – Copper is almost as good as silver and better than gold. Copper is widely used in the electrical and electronics industries. The average car has been calculated to contain more than 22 kilograms (approximately 48 pounds) of pure copper.

Corrosion Resistance – Copper can be applied where it will be exposed to corrosive agents such as salt water. One of the reasons why this material is used on the exterior of the Statue of Liberty in New York, for example. It is worth mentioning that it also has the function of anti-ultraviolet radiation.

Processing safety – CNC machined copper parts do not generate sparks – safe for use in hazardous environments and explosion-hazardous areas.

Bactericidal, viral and fungicidal properties – it makes copper a perfect material for the production of antimicrobial doorknobs and doorknobs (especially in public places, clinics and hospitals), sometimes used in specialized wound dressings (along with silver) and in agriculture (For example, for some types of crops, “copper spray” is used due to its fungicidal properties).

Copper is easily recycled – it is estimated that more than 80% of the copper mined to date is in continuous use. Even after repeated processing, the material does not lose its properties.

CNC Machining Copper: 2 Things to Consider

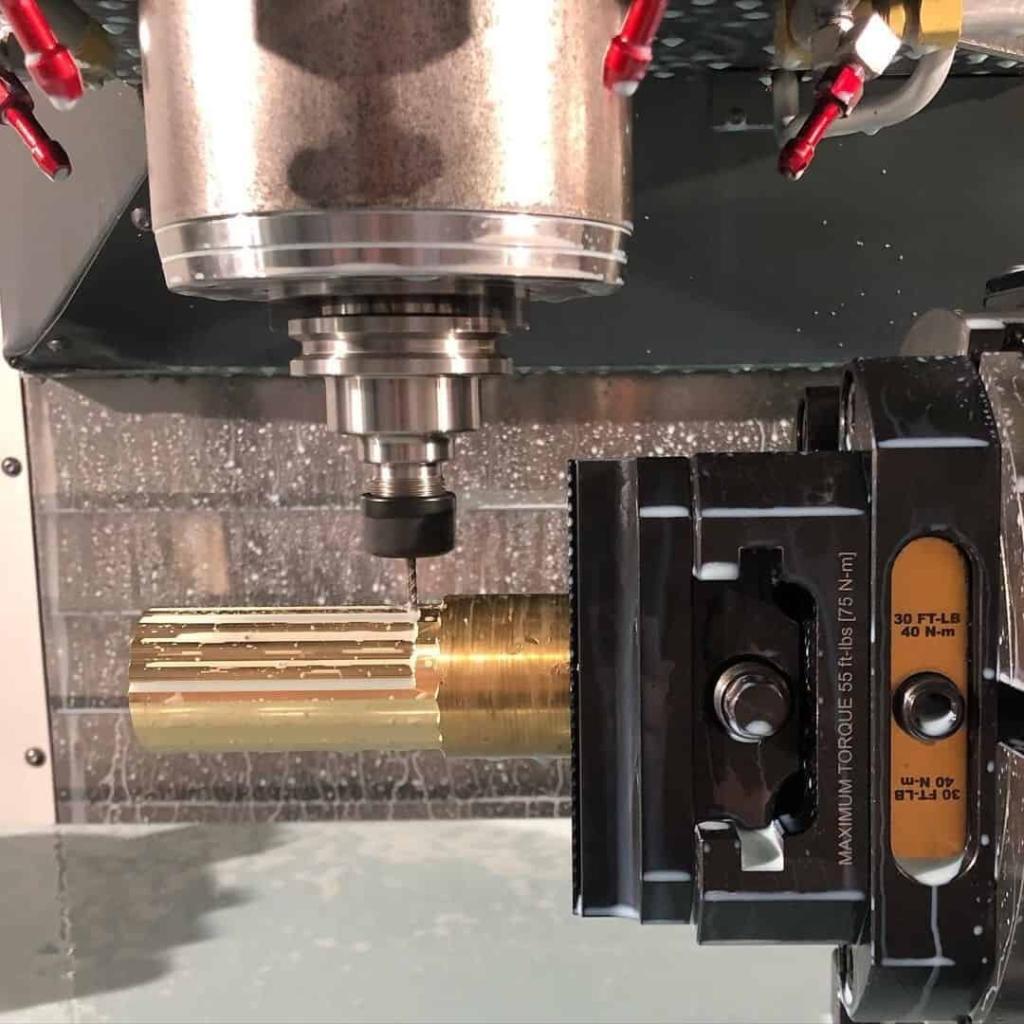

1 Choose the right CNC machining tool

Since copper is very soft, this often results in tool wear and poor chipping during CNC machining. In CNC machining, built-up edge occurs when a portion of the copper workpiece breaks off and is bonded to the cutting tool, resulting in poor surface finish on the machined copper part.

AN-Prototype recommends that you use cutting tools made of high-speed steel (HSS) for CNC machining copper, as they are known to ease these barriers. Additionally, cutting tools must be ground to a good cutting edge before CNC machining copper.

2 Set the correct feed rate

Feed rate describes the rate at which the CNC cutting tool feeds (or advances) relative to the workpiece. We recommend low to moderate feed rates when CNC machining copper, as high feed rates often result in high temperatures, making copper more difficult to precision machine. A general recommendation is to remove no more than 0.2mm of material per pass. The tool feed rate should be maintained at 4-6 mm/s and the depth of cut should not exceed 30% of the tool diameter.

But if your product requires high feed rates, be sure to use cutting fluid (or coolant) to dissipate the heat.

Types of CNC Machining Copper

Copper 101

Copper C101 is the name for an extremely pure copper that is approximately 99.99% copper. This high level of purity gives it excellent electrical conductivity and is often referred to as HC (high conductivity) copper. It is also used as a base material for brass and bronze alloys. Its high conductivity makes it ideal for bus bars, coaxial cables.

- Ultimate tensile strength : 220 - 280 MPa

- Yield strength : 60 - 240 MPa

- Young's modulus :115 - 120 GPa

- Elongation at break :9 - 30 %

- Electrical resistivity :1.71 - 1.76 μΩ*cm

Copper C110

Copper C110 or electrolytic tough copper (ETP) is another high purity option. However, it is not as pure as copper 101, but contains 99.90% copper. It is the most widely used copper alloy because it is more cost-effective and suitable for most electrical applications. This grade is also easier to CNC machine than copper 101.

- Ultimate tensile strength :220 - 280 MPa

- Yield strength :60 - 240 MPa

- Young's modulus :125 - 135 GPa

- Elongation at break :9 - 30 %

- Electrical resistivity :1.7 - 1.74 μΩ*cm

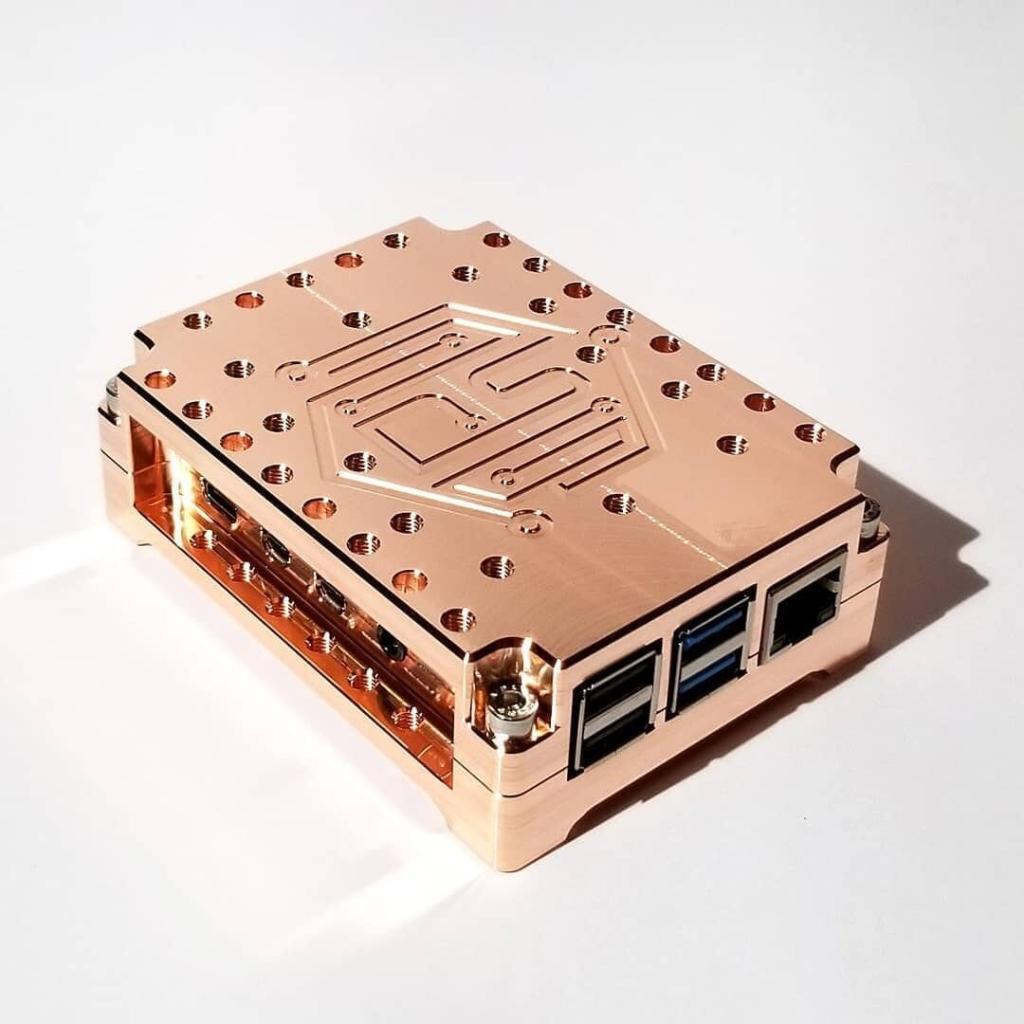

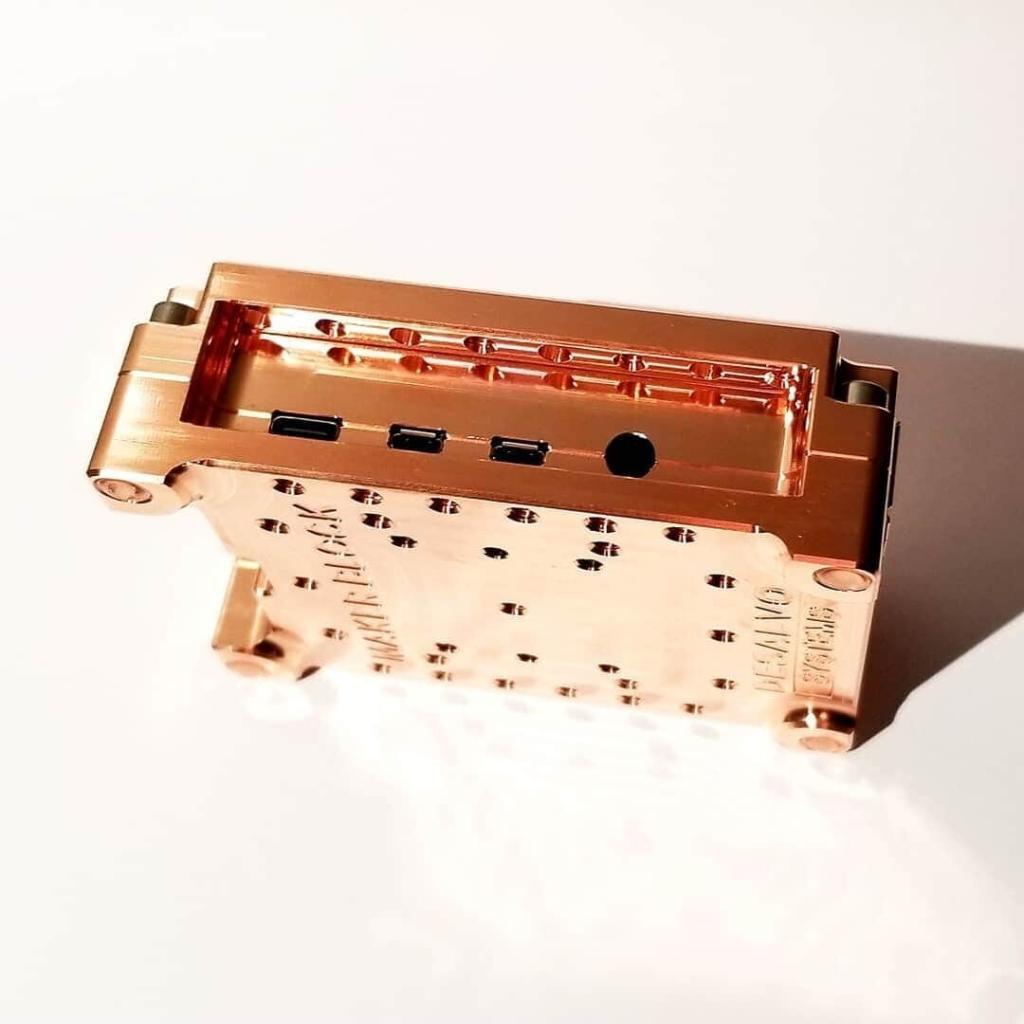

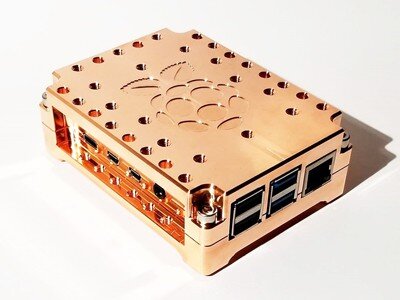

AN-Prototype provides a complete CNC machining copper service, fully capable of manufacturing complex copper parts in C110 and C101. Copper parts are corrosion resistant and versatile, and can be used in applications that require electrical conductivity and higher quality aesthetics. We operate 3-, 4-, and 5-axis CNC mills and turning centers, and are able to machine anything you need, from simple “as-machined” workholding to complex organic geometries with tight tolerances. AN-Prototype can provide up to 7 different post treatment/surface treatment options including sandblasting, powder coating, smooth finishing and polishing.

CNC Machining Copper Gallery