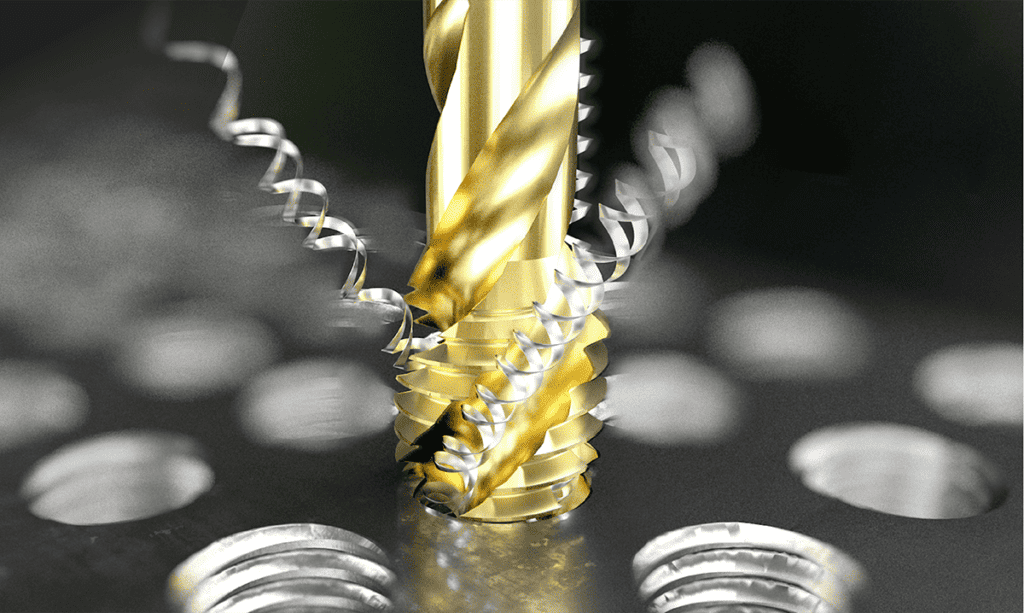

CNC drilling is the process of machining a circular hole in a stationary workpiece using a rotating cutting tool or drill. The holes machined are sized with CNC drill bits, usually to accommodate screws or bolts for assembly purposes. Therefore, CNC drilling processes are common in parts that require component assembly. Apart from this, CNC drilling is also used for aesthetic purposes.

Table of Contents

ToggleHow does CNC drilling work?

The process of CNC drilling has similar steps to operations such as CNC milling, CNC turning, and boring. These include:

1. Create a digital design of the component in CAD software. The first step in manufacturing a drilled component is to create a CAD file of the drilled component in software such as Autodesk Inventor or SolidWorks. The CAD file will provide the machinist with technical information about the component, such as tolerances, dimensions, quantities, etc.

2. Convert the design into machine instructions. Once the component design is finalized, it needs to be converted into a language that the CNC unit can understand, such as formats such as STEP and STL. This step typically requires running the CAD design through CAM software to generate machine-understandable G-code.

3. Load the instructions into the CNC machine. When instructions are loaded into a CNC machine, machine G-code controls how the CNC machine and cutting tools move and operate throughout the drilling process, such as rotational and linear motion, tool paths, speeds, and other functions.

4. Set up the CNC machine. Setting up a CNC machine usually means installing the drill bit and securing the workpiece to specifications.

5. Perform drilling operations. After turning on the CNC machine, the machinist can start the CNC drilling operation.

6. Evaluate components. After the CNC drilling operation is completed, the machinist inspects the part for any errors or defects.

Advantages of CNC drilling

CNC drilling rigs offer many advantages over traditional drilling techniques.

Higher accuracy. Drilling machines integrated with CNC technology can produce holes that fit the requirements more precisely. The tolerance of CNC drilling depends on the complexity of the machine and the sharpness of the drilling tool.

More material options. CNC drilling rigs are compatible with a variety of materials, from wood to plastic to metal. In addition, since CNC machine tools can accommodate multiple drill bits, a variety of holes can be machined in one go. A good example is a multi-spindle drill press, which allows you to install multiple drill bits and drill holes into a workpiece simultaneously.

Higher replication capabilities. Since the CNC drilling device is controlled by a computer, the CNC machine realizes full automation and avoids manual operation. Therefore, there are almost no errors in the CNC drilling process and it is less prone to errors. Rapid manufacturers can achieve a high degree of hole consistency throughout batches and batches.

Types of CNC Drilling Machines

CNC drilling can be accomplished using several types of drill presses, and like any other CNC machine tool, each drill press has its characteristics and capabilities. Here are the common machines you can use and their basic and specific uses.

Vertical drill press. It features a gear-driven spindle head specifically designed for CNC drilling heavy, large parts. It can be CNC or manual and requires a machinist to feed the workpiece to the cutting tool.

Radial drill press. This type of CNC drilling machine uses a basic mechanism that positions a movable spindle on a fixed workpiece. Grinding heads provide cutting tools with enough versatility to perform a variety of operations on parts of most sizes and shapes. As a result, it is more versatile and capable of performing a variety of drilling operations not seen in previous types.

Row drilling rig. Row drills have multiple working heads (to avoid confusion with spindles, there may be multiple spindles in one working head). Typically, these work heads are located above the workbench where parts are fixed or mounted. It can perform multiple consecutive operations simultaneously.

Multi-axis drill press. It has multiple spindles connected to a work head, and all spindles feed the workpiece simultaneously. Such machines are highly needed to produce parts with a large number of holes close to each other. These are the most common machines found among many CNC machining service providers and are suitable for manufacturing porous parts.

The micro drilling machine is currently the most precise small chuck CNC drilling machine. The micro drilling machine has a small chuck and high precision. Therefore, they are suitable for drilling components that require high tolerances and precision.

Turret drill press. Turret drilling machines have multiple work heads mounted on a turret. It enables quick change of cutting tools and positioning them on the workpiece. This type of drill press has a turret with multiple working heads. Therefore, they are suitable for drilling operations that require constant changes in the position of the tool on the workpiece.

Precautions and tips for CNC drilling and Designing

To optimize the CNC drilling process, designers must consider factors such as drill entry and exit surfaces, hole straightness, chip clearance, threaded product design, hole shape and overall part layout. Optimizing every aspect contributes to the overall success of CNC drilling and improves the final quality and functionality of the part.

1. Choose the right CNC drill bit

Selecting the right drill bit based on material, structure, and functionality can be challenging and is a common cause of defects in manufactured drill holes. You can discuss the best approach by consulting a CNC drilling expert or service provider.

2. The drill bit is perpendicular to the entrance

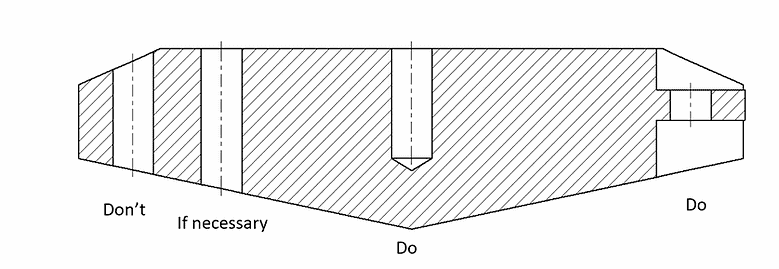

The drill entry surface should be perpendicular to the drill bit, this helps ensure the hole is in the correct location, as shown in the picture below.

The exit surface of the drill should also be perpendicular to the axis of the drill to avoid breakage issues as the drill exits the workpiece, as shown below.

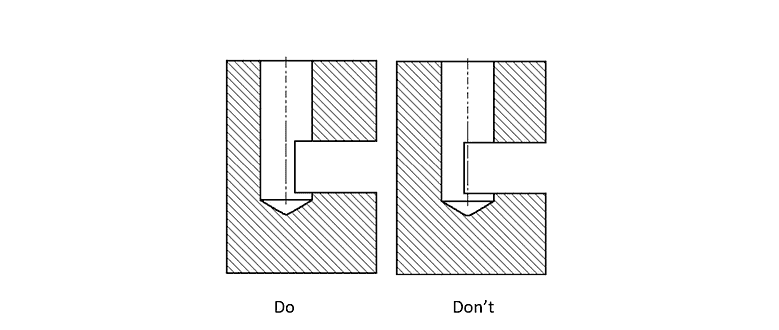

3. Avoid interrupted cutting

If the straightness of the finished hole is particularly critical, it is best to avoid interrupted cuts. If the drill bit intersects another opening on one side, some deflection will occur. Even if straightness is not critical, the center point of the drill bit must remain in the material throughout the cutting process to avoid extreme deflection and possible drill bit breakage.

4. Use standard drill bits

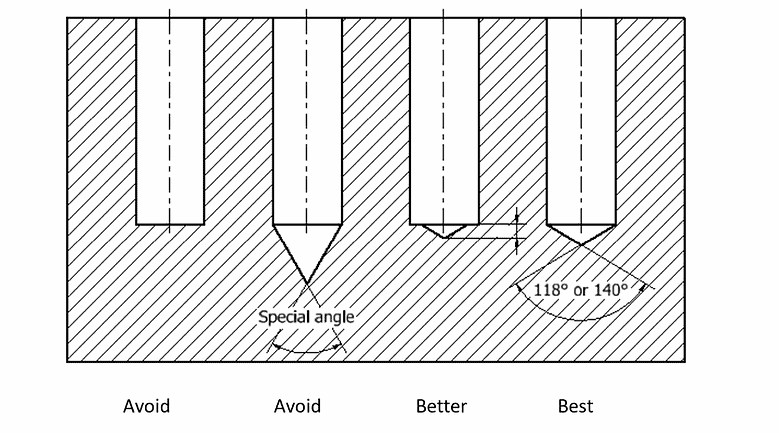

The bottom shape of the blind hole should be the shape drilled with a standard drill bit, as shown in the picture below. When flat bottom holes are required, the use of standard drill points (118° or 140° for stainless steel) is permitted.

5. Avoid using deep holes

Avoid using deep holes (more than 8 times the diameter) as this can cause chip clearance issues and possible straightness deviations. Special drill bits on the market can reach 40x diameter, but their cost is much higher; they should be avoided.

6. Avoid designing parts with small holes

If the part’s application does not require small dimensions, avoid designing parts with small holes. This is because small drill bits are more likely to break. For ease of production, a diameter of approximately 3 mm is an ideal minimum.

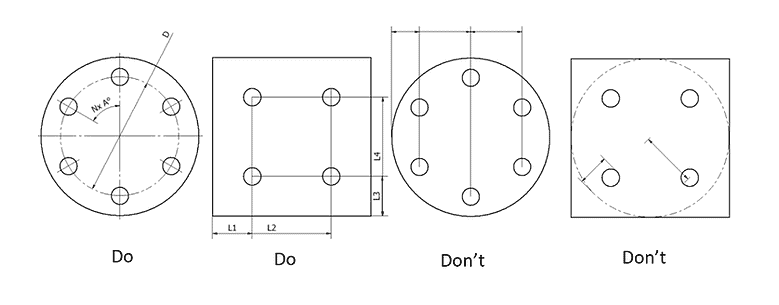

7. Cartesian coordinates

Use rectangular coordinates instead of angular coordinates to specify the location of holes on milled parts. For machinists, they make it easier and safer to lay out parts or drill tools. For turned parts, the center of the part is the natural origin of the dimensions.

8. Feed and speed

Make sure you figure out how to reduce speed and feed rates to maintain productivity. These factors depend on the cutting shape and material type.

9. Chip removal and breakage

Chips must be effectively discharged during CNC drilling and after machining. It is very important to control them as they can cause some problems. You could try using a specialized chip-breaking drill bit. In addition, use coolant when necessary to improve heat dissipation.

Difference between CNC drilling and tapping

CNC drilling is the process of pressing a drill bit into the workpiece to create a hole in the workpiece. CNC thread tapping is the process of creating threaded holes in a workpiece, utilizing a tap to create a continuous spiral ridge in the workpiece. So, the biggest difference between them is that CNC drilling involves creating holes, while thread tapping involves creating threads within existing holes.

Additionally, another major difference between CNC drilling and thread tapping is the type of drill bit used. CNC drilling generally uses twist drill bits, while thread tapping generally uses tap drill bits. Tap drill bits are designed specifically for creating threads and are therefore not suitable for use in CNC drilling applications.

Application of CNC drilling

CNC drilling is widely used. AN-Prototype summarizes some common applications of drilling:

Sheet Metal Fabrication

Sheet Metal Fabrication is suitable for drilling parts such as dashboards, engines etc. in the automotive, aerospace and construction industries. It works with other CNC machining processes such as milling and turning.

Wood Manufacturing

Drilling operations are a critical part of wood manufacturing. With this machine, lumber manufacturers can enjoy automation, accuracy, precision, and high tolerances. Additionally, the industry values aesthetics, which is guaranteed by craftsmanship.

Precision CNC drilling services

Due to various factors such as high initial investment costs, operating errors, and maintenance, it is not cost-effective for designers to purchase their drilling rigs. Therefore, outsourcing to a custom CNC machining service provider is a better approach. At AN-Prototype, we offer on-demand custom manufacturing services that can help you create precision machined parts, not just CNC drilling. We also specialize in other manufacturing processes such as CNC machining services, sheet metal fabrication, 3D printing and injection molding, vacuum casting, and more. Whether your parts are complex and require drilling, tapping, or other surface treatment services, AN-Prototype will meet your needs with high-quality standards. So upload your CAD files now and get quality service at competitive prices and fast delivery times.