CNC machining is the most common manufacturing process in the manufacturing industry and is highly compatible with a variety of metal materials. Among metal materials, stainless steel and titanium are the two most commonly used materials when CNC machining custom parts or prototypes. These two metal materials with a similar appearance are very versatile. All around us we find CNC stainless steel and titanium parts in many different applications.

And, application overlap between the two is common: in the medical field, for example, stainless steel has always dominated. It was not until the 1980s that titanium began to gradually replace stainless steel due to its higher biocompatibility and strength-to-weight ratio. CNC stainless steel and titanium parts are widely used in the aerospace industry, from jet engines to cockpits to landing gear. Both stainless steel and titanium are impact-resistant, durable, and highly resistant to corrosion. In this article, we will provide an in-depth analysis of the differences between stainless steel and titanium in the CNC machining process from different perspectives to guide the selection of the best material for your next CNC project.

Table of Contents

ToggleWhat is stainless steel?

Stainless steel is an alloy of steel and carbon containing at least 10.5% chromium by mass and a maximum of 1.2% carbon by mass. The corrosion resistance and mechanical properties of stainless steel can be further enhanced by adding other elements such as nickel, molybdenum, titanium, niobium, and manganese. Stainless steel is steel mixed with one or more elements to change its properties. When stainless steel comes into contact with air, moisture or water, a thin, impermeable oxide film forms on its surface. This passivated oxide layer protects its surface and has unique self-healing capabilities.

5 types of stainless steel

Stainless steel can be divided into five different types. These include:

- Ferritic Stainless Steel

- Austenitic Stainless Steel

- Martensitic Stainless Steel

- Duplex Stainless Steel

- PH Stainless Steel

Ferritic Stainless Steel

Ferritic stainless steels contain approximately 10.5% to 30% chromium, have less carbon (C<0.08%), and contain no nickel. Ferritic stainless steels have a predominantly ferritic microstructure at all temperatures and cannot be hardened by heat treatment and quenching. Although some ferritic grades contain up to 4.00% molybdenum, chromium is the primary metal alloy component. Additionally, they have relatively low strength at high temperatures. The biggest advantage of ferritic steel is its ability to resist stress corrosion cracking. This capability makes them an attractive alternative to austenitic stainless steels in applications where SCC occurs in chloride environments. Some grades of ferritic stainless steel, such as 430 stainless steel, have strong corrosion resistance and high heat resistance.

430 stainless steel

430 stainless steel has excellent corrosion resistance, higher thermal conductivity, lower thermal expansion coefficient and better thermal fatigue resistance than austenitic stainless steel. It contains the stabilizing element titanium, so the weld has strong mechanical properties. 430 stainless steel is often used in architectural decoration, fuel burner components, household appliances and household appliance components.

430F is an enhanced version of 430 stainless steel, improving its cutting performance. It is mainly used in the manufacture of automated lathes, bolts and nuts. 430LX is an alloy that adds Ti or Nb to 430 steel to reduce carbon content and improve processing and welding properties. It is mainly used to manufacture hot water tanks, hot water supply systems, sanitary ware, household appliances, durable appliances, bicycle flywheels, etc.

Austenitic stainless steel

Austenitic stainless steels range in Cr content from 16% to 25% and can also contain nitrogen, both of which help improve their corrosion resistance. Austenitic stainless steels have the most corrosion resistance of all stainless steels, as well as excellent low-temperature properties and high-temperature strength. Austenitic Stainless SteelThe elements nickel, manganese and nitrogen determine austenitic stainless steel’s non-magnetic face-centered cubic (fcc) microstructure and its ease of welding.

Austenitic stainless steel cannot be hardened by heat treatment, but it can be hardened to high strength levels by other means while maintaining good ductility and toughness. The most well-known austenitic stainless steel grades are 304 stainless steel and 316 stainless steel. They have excellent resistance to various environmental conditions and a wide range of corrosive media.

304 stainless steel

Among austenitic stainless steels, 304 stainless steel is widely used. Its main chemical element is iron, but it has a high nickel content (8% to 10.5% by weight) and a high chromium content (18% to 20% by weight), and also contains other alloying components such as manganese, silicon and carbon. Due to its high chromium and nickel content, 304 stainless steel has good corrosion resistance. Common uses for 304 stainless steel include refrigerators and dishwashers, commercial food processing equipment, fasteners, pipes, heat exchangers, and more.

316 stainless steel

316 stainless steel is similar to 304. It contains mostly iron and high concentrations of chromium and nickel. It also contains silicon, manganese and carbon. The chemical composition of 304 and 316 stainless steel is different, with 316 containing 2 to 3% molybdenum (by weight), while the molybdenum content in 304 is negligible. Grade 316 has higher corrosion resistance due to its higher proportion of molybdenum. When it comes to austenitic stainless steels for marine applications, 316 stainless steel is often considered one of the best choices. 316 stainless steel is also commonly used in chemical processing and storage equipment, refineries, medical equipment and marine environments, especially those containing chlorides.

Martensitic Stainless Steel

Martensitic stainless steel is similar to ferritic steel in that it contains 12% to 14% chromium and 0.2% to 1% molybdenum, but its carbon content is as high as 1% and usually contains no nickel. Because martensitic stainless steel contains more carbon, like carbon and low-alloy steels, it can be quenched and tempered to increase its hardness. Martensitic stainless steel has moderate corrosion resistance and is strong and slightly brittle. Unlike austenitic stainless steel, martensitic stainless steel is magnetic and can be non-destructively tested using magnetic particle testing methods. Typical products of martensitic stainless steel include tableware and medical surgical instruments.

Duplex stainless steel

As the name suggests, duplex stainless steel is a blend of the two most common stainless steel types. They have a mixed microstructure of austenite and ferrite, resulting in a 50/50 mixture, whereas the ratio in commercial duplex stainless steel alloys may be 40/60. The corrosion resistance of duplex stainless steels is roughly equivalent to that of austenitic stainless steels. Nonetheless, their resistance to stress corrosion (especially chloride stress corrosion cracking), tensile strength, and yield strength (approximately twice that of austenitic stainless steels) are generally higher. The carbon content in duplex stainless steel is usually less than 0.03%. Their chromium content ranges from 21.00% to 26.00%, and their nickel content ranges from 3.50 to 8.00%. Duplex stainless steels may contain molybdenum (up to 4.50%). Duplex stainless steels generally have toughness and ductility between those of austenitic and ferritic steels.

Based on their corrosion resistance, duplex steels are divided into: standard duplex steels, super duplex steels and simplified duplex steels. Super duplex steels offer higher strength and resistance to all types of corrosion compared to conventional austenitic steels. Super duplex steels are often used in marine, petrochemical plants, natural gas, desalination plants, heat exchangers and papermaking.

PH stainless steel

PH stainless steel (precipitation hardened stainless steel) contains about 17% chromium and 4% nickel, which is an optimal combination of martensitic and austenitic properties. PH stainless steels are known for their ability to be heat treated to develop high strength (similar to martensitic stainless steels) and also have the corrosion resistance of austenitic stainless steels. These alloys maintain their strength and corrosion resistance even at high temperatures, making them ideal for use in the aerospace sector.

Precipitation-hardened stainless steels have higher tensile strengths due to precipitation hardening of a martensite or austenite matrix caused by heat treatment techniques. Precipitation hardening stainless steel is hardened by the addition of one or more elements: copper, aluminum, titanium, niobium and molybdenum. PH stainless steel is generally the best choice for high strength, toughness and corrosion resistance of all available stainless steel grades.

What is titanium?

Titanium is a silvery, shiny metal with a density of 4.506 g/cm3 and a melting point of 1,668°C. Titanium’s two most outstanding properties are corrosion resistance and its highest strength-to-weight ratio. Titanium is 30% stronger than steel but nearly 43% lighter and 60% heavier than aluminum but twice as strong. Titanium has a low thermal expansion coefficient and high hardness. Although titanium is not as hard as some heat-treated steels, it is non-magnetic, does not exhibit a ductile-to-brittle transition, has good biocompatibility, and is a poor conductor of heat and electricity. However, titanium rapidly absorbs oxygen and nitrogen at temperatures above 500°C, leading to potential embrittlement problems. Titanium is important in several high-performance applications, including aerospace, automotive, medical, robotics, luxury marine equipment, and industrial machinery.

Typical grades of titanium

#1 Grade 1

Grade 1 titanium is the first of four commercially pure titanium grades. It is the most flexible and ductile grade of pure titanium. Grade 1 titanium offers maximum formability, best corrosion resistance and highest impact toughness. Because of these excellent properties, Grade 1 titanium sheet and tubing is the material of choice for any application that requires ease of forming. Here are some examples:

- Chemical Processing

- Desalination

- Architecture

- Medical industry

- Marine industry

- Auto parts

- Aircraft structure

#2 Grade 2

Grade 2 titanium is known as the “workhorse” of commercially pure titanium and has many properties similar to grade 1 titanium but is significantly stronger. Both have equal corrosion resistance. Grade 2 titanium offers excellent weldability, strength, ductility and formability. Therefore, Grade 2 titanium rods and plates are the first choice for a variety of applications:

- Architecture

- Medical industry

- Marine industry

- Exhaust pipe guard

- Aircraft skin

- Chemical Processing

- Chlorate production line

#3 Grade 3

Grade 3 titanium is the least commonly used of commercially pure titanium grades, but that doesn’t make it any less valuable. Grade 3 is stronger than Grades 1 and 2, has similar ductility, but slightly less formability, but has higher mechanical properties. Level 3 is used for applications requiring moderate strength and significant corrosion resistance. Here are some examples:

- Aerospace structures

- Chemical processing

- Medical industry

- Marine industry

#4 Grade 4

Grade 4 titanium is the strongest of the four commercially pure titanium grades and is known for its high corrosion resistance, formability, and weldability. Although Grade 4 titanium has traditionally been used in the following industrial applications, more recently it is often used in medical devices. It is needed in applications requiring high strength:

- Airframe parts

- Cryogenic container

- Heat exchanger

- CPI device

- Condenser pipes

- Surgical equipment

Titanium alloy

Titanium alloys have excellent mechanical properties and CNC machining properties, such as high strength-to-density ratio, high corrosion resistance, high fatigue crack resistance, resistance to moderate high temperatures without creep, etc., and are widely used as structural materials in the aerospace industry. Supersonic aircraft and spacecraft as well as non-aerospace segments such as military, automotive and sporting goods. Because titanium alloys are biocompatible, non-toxic and not rejected by the body, they are also popular in medical applications, including surgical instruments and implants such as joint replacements, which can last up to 20 years.

Typical titanium alloy

#1 Grade 7

Grade 7 titanium is mechanically and physically identical to grade 2 and contains the interstitial element palladium. Grade 7 titanium alloy is the most corrosion-resistant of all titanium alloys and has good weldability, machinability and corrosion resistance. Level 7 is often used to manufacture parts for chemical production lines.

#2 Grade 11

Grade 11 titanium is similar to grade 1 with trace amounts of palladium added to improve corrosion resistance. This corrosion resistance is important to prevent crevice erosion and reduce acid levels in chloride environments. Grade 11 titanium’s properties also include high ductility, cold formability, reliable strength, impact toughness and weldability. This alloy is suitable for the same titanium applications as Grade 1, especially where corrosion is an issue, such as:

- Chemical production

- Chlorate manufacturing

- Desalination

- Applications in the ocean

#3 Grade 12

The excellent weldability of grade 12 titanium makes it an excellent titanium alloy. It is a long-lasting alloy with high strength at high temperatures. Grade 12 titanium has the same properties as 300 series stainless steel. This alloy can be manufactured hot or cold using press brakes, hydraulic presses, drawing or drop weight methods. Because it can be molded in a variety of forms, it has value in a wide range of applications. The corrosion resistance of grade 12 titanium is important to equipment manufacturers where crevice corrosion is an issue. Grade 12 is suitable for the following industries and applications:

- Heat exchanger and housing

- Hydrometallurgical applications

- High temperature chemical manufacturing

- Marine and aircraft components

Stainless Steel vs. Titanium: What’s the Difference?

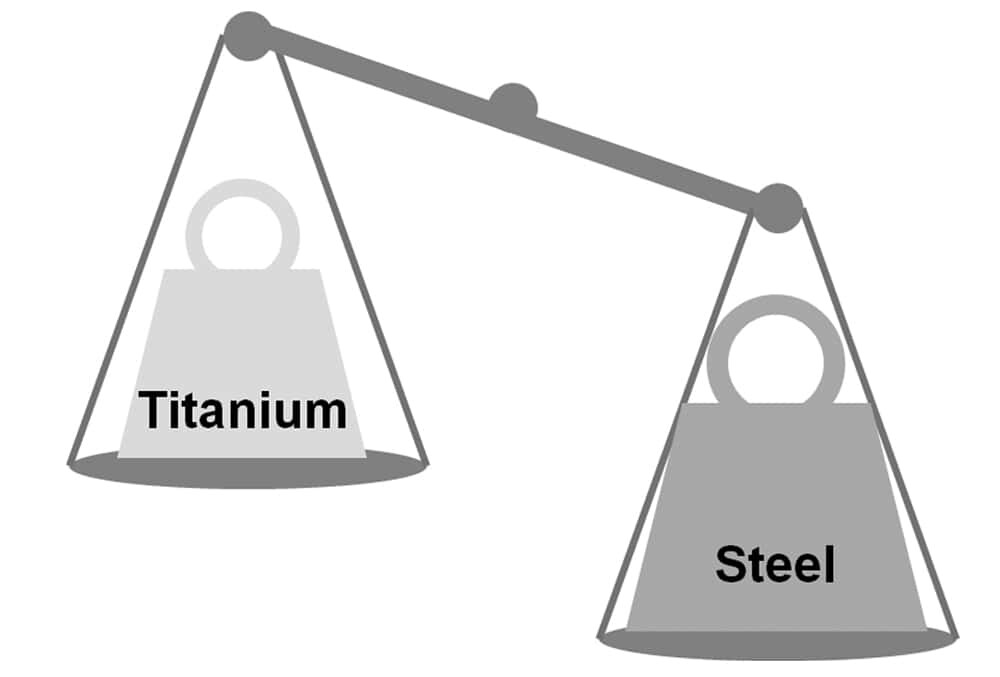

Titanium and stainless steel are widely used in a variety of consumer and industrial applications. What is the difference between stainless steel and titanium? Titanium and stainless steel have unique properties that make them different from each other. We will compare titanium and stainless steel using different properties for easier understanding.

#1 Elemental composition

Titanium and stainless steel have different elemental compositions. Generally speaking, commercial pure titanium uses titanium as the main element and also contains nitrogen, hydrogen, oxygen, carbon, iron, nickel and other elements with a content of 0.013% to 0.5%. Titanium can be combined with other metals to form stronger titanium alloys that are highly corrosion-resistant yet lightweight. Stainless steel, on the other hand, is composed of a variety of elements, and steel is corrosion-resistant only when the Cr content reaches a certain value, so it contains at least 10.5% chromium and additional elements, with other alloy components ranging from 0.03% to more than 1.00%. The chromium content in stainless steel helps prevent corrosion and provides heat resistance. Other elements are aluminum, silicon, sulfur, nickel, selenium, molybdenum, nitrogen, titanium, copper and niobium.

#2 Density

The density of titanium metal is 4.51 g/cm3, and the density of stainless steel is 7.70-7.90 g/cm3. Titanium is much lighter than stainless steel, making it ideal for applications where weight is a primary consideration. Additionally, titanium has a higher strength-to-weight ratio than stainless steel, meaning it can support more weight while still being lightweight.

#3 Melting Point

The melting point of titanium is 3,027°C. The melting point of stainless steel is 1,416-1,537°C. Titanium has a much higher melting point than stainless steel, making it suitable for applications requiring extreme temperatures. Additionally, because titanium alloys can withstand high temperatures better than stainless steel, they are well suited for aerospace and automotive applications.

#4 Hardness

A material’s hardness refers to its response to etching, deformation, scratches, or dents on its surface. The Brinell hardness test is used by manufacturers and consumers of high-strength materials.

While the Brinell hardness of stainless steel varies greatly depending on alloy composition and heat treatment, it is generally tougher than titanium. Titanium, on the other hand, can quickly deform when it is indented or scratched. To avoid this, titanium develops an oxide layer called a titanium oxide layer, which creates an extremely hard surface that can resist maximum penetrating pressure. Stainless steel typically has a Brinell hardness in the 180-400 range, while titanium has a Brinell hardness in the 100-200 range.

#5 Corrosion resistance

The corrosion resistance of titanium alloy is much better than that of stainless steel, and it is widely used in humid atmosphere and seawater media; it has strong resistance to pitting corrosion, acid corrosion, and stress corrosion; it has excellent resistance to alkali, chloride, chlorine, nitric acid, sulfuric acid, etc. corrosion resistance. However, titanium has poor corrosion resistance to reducing oxygen and chromium salt media.

However, stainless steel can still become highly resistant to corrosion because of the presence of chromium. This alloy not only improves the metal’s corrosion resistance but also makes it more durable.

#6 Durability

The ability of a material to continue to function without undue repair or maintenance during its half-life is an indicator of a material’s durability. Both titanium and stainless steel are durable due to their superior properties. Titanium is approximately 3 to 4 times stronger than stainless steel.

#7 Elasticity

Elasticity is a measure of a material’s flexibility. This means that it evaluates how easily a material can bend or warp without deforming. The normal elasticity of stainless steel is 200 GPa, while the normal elasticity of titanium is 115 GPa. Since most alloys are more elastic, stainless steel often outperforms titanium in this regard. Likewise, greater flexibility makes it easier to CNC mill stainless steel and fabricate different parts. This is an important indicator because it directly affects CNC machining costs.

#8 Tensile Strength

The ultimate tensile strength of a material is the maximum value on the engineering stress-strain curve. This is the maximum stress that a material in tension can withstand. Most of the time, ultimate tensile strength is abbreviated as tensile “strength” or “ultimate”. Stainless steel has a higher ultimate tensile strength than titanium.

The important thing to remember here is that while stainless steel has greater overall strength, titanium is stronger per unit mass. Therefore, if overall strength is the primary driver of application selection, stainless steel is often the best choice. If weight is most important, titanium may be a better choice.

#9 Yield Strength

The yield stress or yield strength of a material is the stress at which it deforms. The yield strength of 304L stainless steel is 210 MPa, while the yield strength of Ti-6AI-4V (titanium grade) is 1100 MPa. As you can see from the difference in elasticity, titanium is more difficult to make but is stronger per unit mass. In addition, titanium is biocompatible, while stainless steel is not fully biocompatible. Because of this, titanium is an excellent choice for a wide range of medical uses.

#10 weight

One significant difference between titanium and stainless steel is their weight. Titanium has a high strength-to-weight ratio, allowing it to provide roughly the same strength levels as stainless steel while weighing only 40% as much. Therefore, titanium is critical for applications that require minimum weight and maximum strength. This is why titanium is useful in aircraft components and other weight-sensitive applications. Steel, on the other hand, is used to make car frames and other items, but it’s often difficult to make items lighter.

#11 Price

In terms of price, titanium is more expensive than stainless steel. As a result, it becomes more expensive for certain industries that require large amounts of titanium, such as aerospace. If cost is an important factor, stainless steel may be better than titanium if both are good enough.

Stainless steel is an affordable option. Since there is no shortage of iron or carbon on Earth, it is easier to make. Additionally, stainless steel does not have complex CNC machining requirements. Stainless steel prices, on the other hand, vary greatly due to the wide variety of options. Carbon and iron alloys are the lowest cost. Those stainless steels made from chromium, zinc or titanium will be more expensive.

#12 Processability

Titanium is more difficult to CNC machining than stainless steel, requiring specialized cutting tools and coolant to prevent wear on the titanium workpiece. Stainless steel, on the other hand, is easier to CNC machine with standard high-speed steel (HSS) or carbide tooling. Overall, stainless steel has many advantages over titanium when it comes to CNC machinability.

#13 Plasticity

Titanium is relatively less malleable, while stainless steel can be made more ductile by adding various alloys. Therefore, stainless steel is generally easier to machine into the desired shape than titanium.

#14 Welding

Titanium alloys can be welded using gas tungsten arc welding (GTAW) or plasma arc welding (PAW). Stainless steel, on the other hand, is more commonly joined via MIG and TIG welding methods. Titanium is difficult to weld and requires a skilled welder and special tools, while stainless steel is easier to weld. Both metals require regular post-weld cleaning and maintenance to keep them in good condition and prevent corrosion.

#15 Thermal conductivity

The thermal conductivity of titanium is λ=15.24W/(m.K), which is about 1/4 of nickel, 1/5 of iron, and 1/14 of aluminum. The thermal conductivity of various titanium alloys is about 50% lower than that of titanium.

The thermal conductivity of stainless steel ranges from 20-60 W/(mK). Generally speaking, stainless steel has a higher thermal conductivity than titanium, making it better suited for applications that require heat transfer or rapid cooling.

#16 Conductivity

Titanium has a conductivity of 18MS/m, stainless steel has a conductivity range of 10-50MS/m, and copper has a conductivity of 100-400MS/m. Overall, copper is much more conductive than titanium or stainless steel, making it better suited for applications that require high conductivity. However, titanium is much lighter than copper and stainless steel and is preferred for certain applications due to its weight advantage.

#17 Application areas

The applications of stainless steel and titanium vary greatly. Stainless steel is ideally suited for construction, paper, pulp and biomass conversion, chemical and petrochemical processing, food and beverage, energy, firearms, automotive, medical industries and 3D printing. Titanium, on the other hand, is well suited for aerospace, consumer applications, jewelry, the medical industry, and nuclear waste storage.

Comparison table of differences between titanium and stainless steel

Titanium and stainless steel have unique and remarkable qualities that differentiate them from each other. To help clarify this comparison, we’ve tabulated the differences between the two for your reference.

Property | Titanium | Stainless Steel | Conclusion |

Durability | It’s a lighter and more corrosion-resistant metal and also more resistant to high temperatures and thermal shock than stainless steel | It’s more resistant to scratches and dents than titanium, and is easier to maintain due to its non-porous surface | Both titanium and stainless steel are highly durable metals, the choice between them up to the specific application |

Cost/Price | It tends to be more expensive than stainless steel due to its higher processing and production costs | It’s generally a cost-saving solution widely used in manufacturing industries | Titanium is ideal for crucial applications such as medical and aerospace, stainless steel is preferred when budget is the prerequisite |

Hardness | It forms a hard oxide layer that resists most forces with high strength-to-weight ratio | Its hardness depends on the alloy composition and manufacturing process used | Both titanium and stainless steel are strong and durable metals used for rough environments |

Weight | Its density is approximately 4.51 g/cm³ | Its density is around 7.9 g/cm³ | Titanium is roughly 40% lighter than steel of the same volume |

Corrosion Resistance | It’s known for its excellent corrosion resistance in a wide range of natural and artificial environments due to the formation of an oxide layer | It has moderate corrosion resistance due to its chromium content which forms a passive film | Stainless steel is more susceptible to corrosion than titanium in certain environments and conditions |

Electrical Conductivity | Its electrical conductivity is about 3.1 x 10^6 siemens/meter | Range from 1.45 x 10^6 to 2.5 x 10^6 siemens/meter depending on the specific grade of stainless steel | Stainless steel is generally a better conductor of electricity than titanium |

Thermal Conductivity | Its thermal conductivity is about 22 W/(m*K) | Varies depending on its composition and can range from 14.4 W/(m*K) to 72 W/(m*K) for austenitic stainless steels | Generally, stainless steel has a lower thermal conductivity compared to titanium due to its greater resistance to heat transfer |

Melting Point | It has a melting point of 1,668°C (3034°F) | It typically has a melting point of 1,400-1,500°C (2,552-2,732°F) | Titanium has a higher melting point compared to stainless steel |

Machinability | It’s difficult to machine as its elastic modulus is low, indicating that it flexes and deforms easily | It has a higher elastic modulus and a lower tendency to stick to cutting tools, making it easier to machine | In general, stainless steel can be easier to machine than titanium due to its lower strength and hardness |

Formability | It has a lower formability than stainless steel due to its lower ductility and work hardening tendency | It’s a ductile and malleable metal, so it can be easily formed into various shapes without breaking or cracking | Usually, stainless steel is easier to work with and has better formability than titanium |

Weldability | It has a high melting point and high reactivity to oxygen, which can make it difficult to weld | It has lower reactivity to oxygen, and its weldability depends on the specific alloy used | Overall, the weldability of titanium is more challenging than that of stainless steel |

Yield Strength | It’s considered one of the strongest metals per unit mass, as it exhibits similar strength to stainless steel at half the density | Depending on the alloying elements, the yield strength of stainless steel varies from 25 MPa to 2500 MPa | Stainless steel is a better choice for projects that require overall strength, while titanium is preferred when strength per unit mass is necessary |

Tensile Strength | Commercially pure titanium has a tensile strength ranging from 240-410 MPa (megapascals), while some high-strength alloys can have a tensile strength of up to 1,400 MPa | The tensile strength of stainless steel typically ranges from 515-827 MPa depending on the grade and type of stainless steel | The tensile strength of stainless steel is generally higher than that of titanium |

Shear Strength | The shear strength of titanium ranges from about 300 to 580 MPa (43,500 to 84,000 psi) | The typical shear strength of stainless steel ranges from 400 to 800 MPa (58,000 to 116,000 psi) | Stainless steel is higher than titanium in resistance against shear load |

Appearance/Color | Titanium is a silver-gray colour in its natural state | Stainless steel has a more silver-like or grayish-white hue | Stainless steel will still have a metal-like shine to it after being coated or finished, whereas titanium’s natural colour will always be visible |

Applications | High strength-to-weight ratio | Highly versatile | Titanium: Aerospace, Industrial, Architectural, Consume, Jewelry, Medical Industry, Storage of Nuclear Waste; |

Titanium vs. Stainless Steel – Pros and Cons

Both stainless steel and titanium have unique properties that make one better suited for your specific needs. Understanding the pros and cons of both metals will help you make your decision. Here are their pros and cons.

Pros of stainless steel

- Cheap and readily available.

- High strength and durability.

- Excellent corrosion resistance.

- Excellent mechanical properties.

- Sustainability and environmental protection.

- High strength and excellent durability.

- Stainless steel is recyclable.

- Easy to customize.

- Stainless steel equipment is easy to clean.

Cons of stainless steel

- Strength will decrease at high temperatures.

- Stainless steel equipment is very heavy.

Pros of titanium

- Amazing corrosion resistance.

- High melting point and high temperature resistance.

- High strength and lightweight.

- Non-toxic and widely used in the medical industry.

- Good biocompatibility.

- Recyclable.

Cons of titanium

- Costly.

- Low elasticity and easy to deform.

- Difficulty in extraction, casting, and processing.

How to choose the right material for your CNC machining project: stainless steel or titanium?

Titanium and stainless steel alloys are widely used in CNC machining. For an in-depth analysis of the performance of these two materials during processing, AN-Prototype has compiled a comparison table between the two based on years of experience. You can also visit our pages detailing CNC machining stainless steel and CNC machining titanium services for more comprehensive details.

Titanium | Stainless Steel | |

Alloys | Titanium Grade 1 | Stainless steel 303 |

Advantages | High strength-to-weight ratio | Good heat resistance |

Disadvantages | High cost | Magnetism limits their use |

Tolerances | It is determined by the desired effect and the titanium used. A tolerance of ±0.005”(±0.13 mm) is achievable. | It is determined by the desired effect and the exact alloy used. A tolerance of ±0.005”(±0.13 mm) is achievable. |

Wall Thickness | A minimum wall thickness of ±0.03”(±0.8 mm). | A minimum wall thickness of ±0.03”(±0.8 mm). |

Part Size | It’s mostly decided by the available machine and part geometry. | It’s mostly decided by the available machine and part geometry. |

Finishes | As machined, Case hardening, Anodizing. | As machined, Powder coating, Bead blasting. |

Conclusion

CNC stainless steel and titanium parts are widely used in various industries, and both alloys offer superior quality. Once the proper equipment and parameters are used, these metal alloys can be used for almost all CNC machining. Using the right stainless steel and titanium alloys requires a thorough understanding of their properties, processing environment, intended functionality and other important factors.

At AN-Prototype, we offer 5-axis CNC machining services for over 160 material options, from metals to plastics and other specialty materials. Our team of skilled engineers performs in-depth analysis to ensure that the CNC machining process meets specific requirements and tolerance limits to create precise components for a variety of applications in different industries. We have a team of highly qualified experts who utilize the latest CNC technology to bring your designs to reality with maximum efficiency, accuracy, and precision.

Get an instant quote and start your CNC machining project today!