AN-Prototype is a leading CNC machining aluminum service provider in China. We have a team of highly qualified engineers, machinists and quality control specialists capable of manufacturing aluminum parts with accuracy and precision. This article explains some of the key advantages of CNC machining aluminum – making it one of our most extensive prototyping and production processes – while also presenting tips for CNC machining aluminum.

Table of Contents

ToggleAN-Prototype CNC Machining Aluminum Capabilities

- Price: $ $

- Tolerances:0.005mm

- Wall Thickness:0.5mm

- Leading Time < 10 Days

- ISO 9001& ISO 13485 Certified

- 3 Axis, 4 Axis, 5Axis CNC Machining

- Max part size:2000 * 1300 * 600 mm

The characteristics of aluminum alloy

Aluminum is a strong, non-magnetic, cost-effective metallic material. It has good mechanical properties and ductility. Its ductility allows it to be made into aluminum foil, while its ductility allows aluminum to be drawn into rods and wire. Aluminum is also highly resistant to corrosion as a protective oxide layer naturally forms when the aluminum block is exposed to air. Aluminum’s natural protective layer makes it more resistant to corrosion than carbon steel. Additionally, aluminum is a good conductor of heat and electricity, better than carbon steel and stainless steel. Aluminum is faster and easier to CNC machine than steel and titanium, while its strength-to-weight ratio makes it one of the best choices for many applications that require a strong, hard material. Aluminum is by far the name of the most abundant metallic element found in the Earth’s crust, which is part of the reason it is used in many of the objects we encounter every day. In fact, aluminum is the most widely used non-ferrous metal, found both in common objects like aluminum foil or aluminum cans, and in extremely demanding applications like spacecraft and submarine parts.

Of course, aluminum has some downsides, it’s not as hard as steel, which makes it a poor choice for parts that are subject to greater impact or extremely high load capacity. Aluminum also has a significantly lower melting point (660°C compared to steel’s lower melting point of about 1400°C), so it cannot withstand extreme high-temperature applications.

Aluminum Is Popular Materials for CNC Machining

CNC machining is a traditional manufacturing technique that uses drills and turning tools to create parts by removing material from a solid block of material. The process is fast and highly repeatable, making it ideal for manufacturing complex parts with tight tolerances. CNC machining can machine almost any material, from plastics to metals to fiberglass, with aluminum being a popular choice of all. Iterations of CNC machines have made aluminum machining much easier, but that doesn’t mean making aluminum parts is any easier than it used to be. With many aluminum grades (or alloys) on the market today, the success of your CNC aluminum project will depend on selecting the most suitable aluminum alloy and the most suitable CNC machining process. Few metals or plastics can match the incredible versatility of aluminum. CNC machining aluminum is three to four times faster than machining other common materials such as steel and titanium.

Aluminum’s flexibility and impressive strength-to-weight ratio make it ideal for use as the skin of everything from cars and trains to planes and ships. Today’s greater emphasis on fuel efficiency and “lightweight” has seen aluminum replace “heavy metals” such as stainless steel and carbon steel traditionally used in the manufacture of components and internal structures. Aluminum’s high corrosion resistance also avoids the bulky and expensive anti-corrosion coatings that other materials often require.

Thanks to its smooth silver finish, it’s also perfect for electronic devices like smartphones, laptops, tablets, and flat-screen TVs. For example, the mobile phone casing made by Apple is made of aluminum. Aluminum is a material that is lighter than steel, stronger than plastic, more reliable, inexpensive, readily available and infinitely adaptable.

- Machinability

Aluminum is easily CNC machined, so it can be cut quickly and accurately with a CNC machine. This leads to some desirable results: first, less time for CNC machining, making it cheaper (since the machinist needs less labor and the machine itself requires less time to operate); second, good cutting Machinability means less deformation of the part when the CNC cutting tool cuts the workpiece. This enables machines to meet tighter tolerances (down to ±0.005 mm) and results in greater precision and repeatability.

- Corrosion Resistance

Aluminum’s electrical conductivity determines its use in the manufacture of electrical components. Although not as conductive as copper, pure aluminum has a conductivity of about 37.7 million Siemens per meter at room temperature. Alloys may have low electrical conductivity, but aluminum materials are significantly more conductive than materials such as stainless steel.

- Aluminum Anodizing

CNC-machined aluminum parts are especially popular in the consumer electronics industry, not only for strength and weight requirements, but also for people’s growing aesthetic demands. Aluminum is anodized to both add a protective oxide finish and achieve a colorful aesthetic. For example, Apple manufactures various types of mobile phone casings, all of which are anodized.

- Recyclability

Aluminum can be recycled to over 95%, making it more suitable for businesses looking to minimize their environmental impact. Recyclable materials are very important for CNC machining, because in the CNC machining process, there will be a lot of waste in the form of chips.

Aluminum CNC Machining Technology

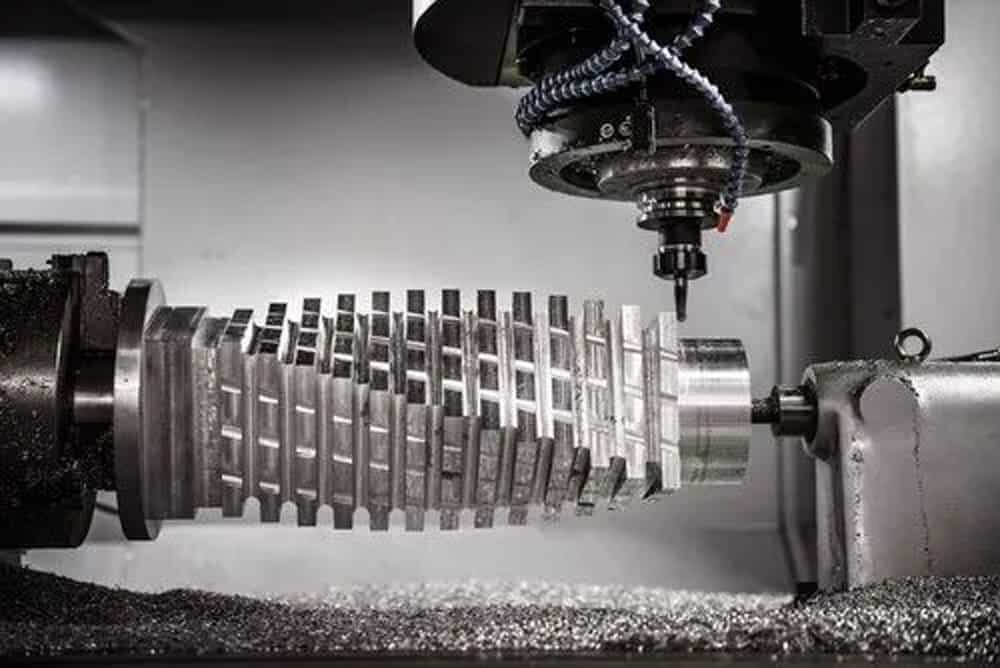

CNC milling is the use of a computer-controlled system combined with a cutting tool, or milling cutter, to cut material from a solid block to create parts made of materials such as metal, plastic, wood, and fiberglass.

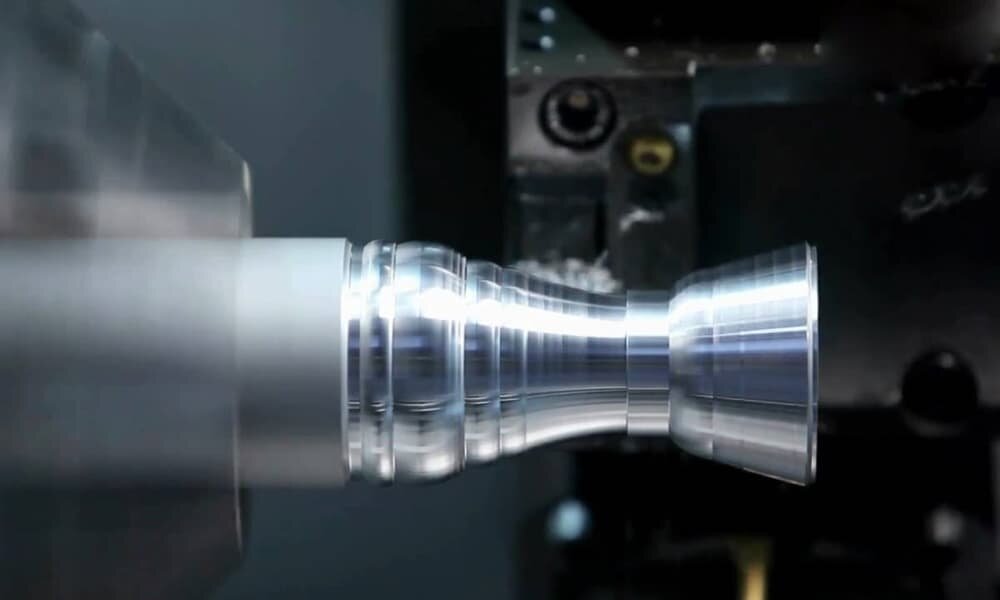

CNC turning is when a rod of material is held in a chuck and rotated while a tool is fed into the workpiece and removes material to create the part in the desired shape. CNC turned parts are mostly circular features.

Swiss CNC Machining

CNC Swiss machining is an advanced manufacturing technique utilizing specialized tool cutting designed to machine metal blanks into complex, slender or delicate components requiring tight tolerances.

CNC Laser Cutting

CNC laser cutting uses a focused, high-power laser beam to cut or engrave material to form custom shapes. It is highly accurate, especially when cutting complex shapes and small holes.

CNC Drilling

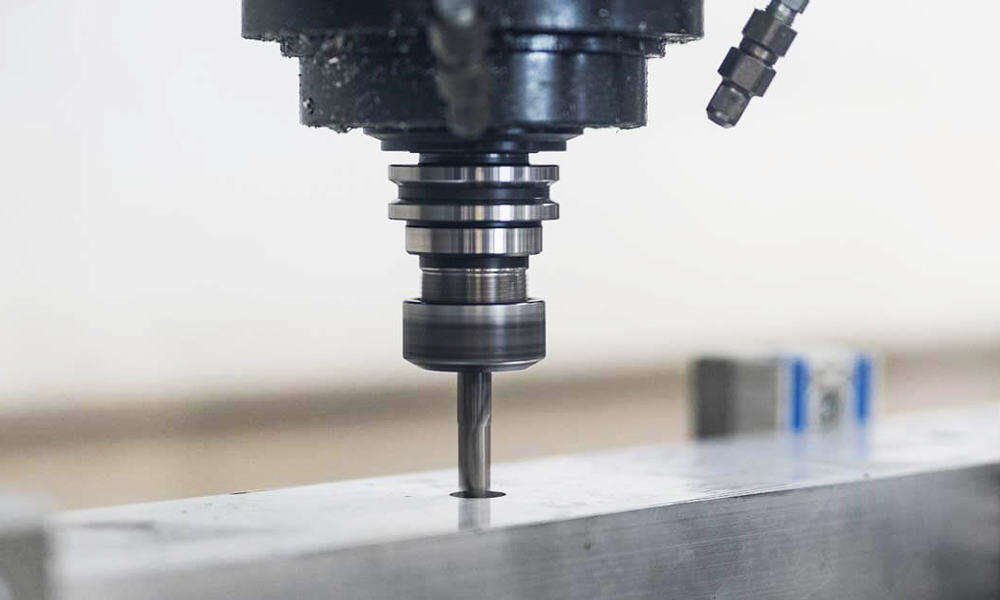

CNC drilling is a machining process that uses a rotating cutting tool to create a round hole in a workpiece. These holes are usually to accommodate screws or bolts for assembly purposes.

CNC Tapping

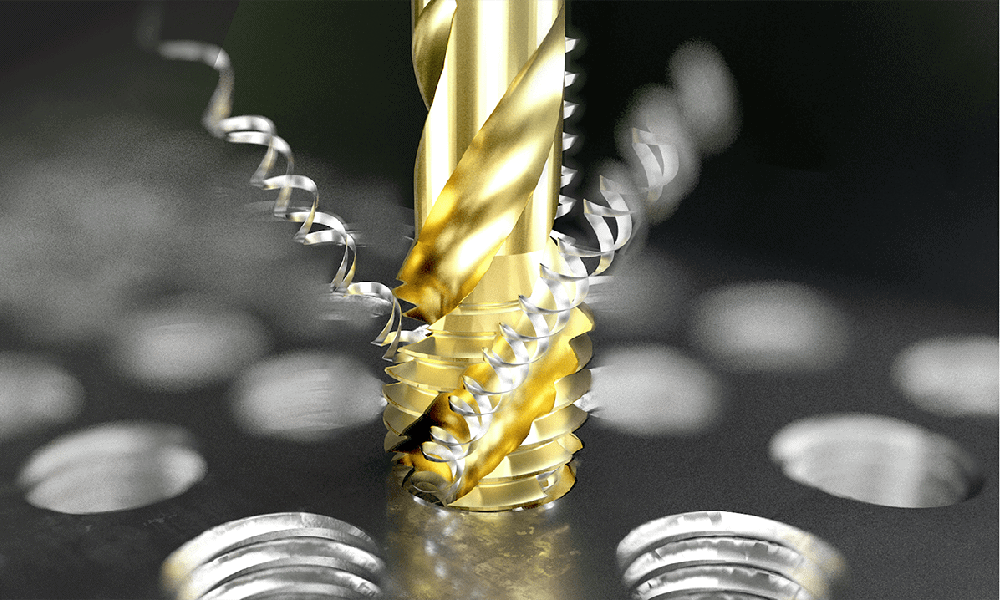

CNC tapping is the process of creating threads on a part. It must be drilled with a tap and threaded in the hole while chamfering the end so that the screw or bolt can be screwed into the hole.

Sinker EDM

Sinker EDM is the process of immersing two conductive parts in some insulating liquid (dielectric) to create high precision parts by controlling the sparks, cooling the workpiece and flushing away eroded particles.

Wire EDM

Wire EDM is a non-contact subtractive manufacturing process that uses thin charged wires and a dielectric fluid to cut metal parts into different shapes, compatible with almost all conductive materials.

CNC Machined Aluminum Grades

Aluminum used in CNC machining projects is not pure – it always contains small amounts of alloying elements. These alloying elements give aluminum extra strength and hardness. Aluminum alloys still contain 99% to 99.6% aluminum (the element) by weight, with the remaining percentages made up of common materials such as silicon, manganese, magnesium, copper, and zinc. By slightly adjusting the content of alloying elements, an infinite number of aluminum alloys can be made. However, some compositions have proven more useful than others. These common aluminum alloys are grouped according to the main alloying elements. Each series has some common properties. For example, 3000, 4000, and 5000 series aluminum alloys cannot be heat treated, so cold working is used, also known as work hardening. AN-Prototype summarizes the characteristics of 8 aluminum alloys based on years of experience in CNC machining aluminum.

- 1000 series aluminum alloy

1xxx aluminum alloys are the purest form of aluminum, containing at least 99% aluminum by weight. Theoretically there are no other alloying elements. For example, Aluminum 1199 is 99.99 percent aluminum and is commonly used to make aluminum foil. 1000-series aluminum alloys are the softest aluminum grades, but they can harden, meaning they become stronger when repeatedly deformed.

- 2000 series aluminum alloy

The 2000 series aluminum alloys use copper as the main alloying element. This grade of aluminum can be hardened and can be nearly as strong as steel. Precipitation hardening involves heating a metal to such a heat that precipitates of other metals come out of the solution of the metal (while the metal remains solid) and help increase the metal’s yield strength. However, 2xxx aluminum grades have lower corrosion resistance due to the addition of copper. 2024 aluminum also contains manganese and magnesium and is often used in aerospace parts.

- 3000 series aluminum alloy

3xxx aluminum alloys have manganese as the most important addition. These aluminum alloys can also be hardened (this is necessary to achieve sufficient hardness, since the 3000 series aluminum cannot be heat treated). Aluminum 3004 also contains magnesium, an alloy commonly used in aluminum beverage cans and its hardened variants. Among them, 3004 aluminum is a common metal used to make beverage cans and their lids.

- 4000 series aluminum alloy

The main alloying element of 4000 series aluminum is silicon. Silicon lowers the melting point of 4xxx grade aluminum. 4043 aluminum is used as a filler bar material for welding 6000 series aluminum alloys, while 4047 aluminum is used in construction as plates and cladding.

- 5000 series aluminum alloy

Magnesium is the main alloying element in the 5000 series. The 5000 series aluminum alloys have the best corrosion resistance, so they are often used in marine applications or other situations facing extreme environments. 5083 aluminum is a metal commonly used in marine parts.

- 6000 series aluminum alloy

The main alloying elements of the 6000 series aluminum alloys are magnesium and silicon. The 6000 series aluminum alloys are generally easy to CNC machine and can be precipitation hardened. Especially 6061 is one of the most common aluminum alloys and also has high corrosion resistance.

- 7000 series aluminum alloy

The main alloying element of the 7000 series aluminum alloys is zinc, sometimes with copper, chromium, and magnesium, and can be the strongest of all aluminum alloys through precipitation hardening. The 7000 series are commonly used in aerospace applications due to their high strength. 7075 is a common grade with higher corrosion resistance than the 2000 series aluminum alloys. Aluminum 7075 is particularly suitable for aerospace applications.

- 8000 series aluminum alloy

The 8000 series is an umbrella term for other classes of aluminum alloys. The 8000 series aluminum alloys contain many other elements, including iron and lithium. For example, 8176 aluminum contains 0.6% iron and 0.1% silicon by weight, and is often used to make wire.

Commonly Aluminum Alloys For CNC Machining Projects

While there are many options to choose from, only some aluminum alloys are suitable for CNC machining. Based on AN-Prototype’s years of experience in CNC machining and rapid manufacturing, the following are the most popular aluminum alloys for CNC projects:

Aluminum 6061-T6

6061-T6 is the most popular aluminum alloy and is used by most rapid manufacturing companies as the standard grade for CNC machining. 6061-T6 is an excellent general purpose, easily CNC machined and can be subjected to different heat treatments. Common applications include bicycle frames, valves, automotive parts, and more.

- Tensile strength: 310 MPa

- Elongation at break: 17%

- Elastic modulus: 68.9 GPa

- Hardness: 60 HRB

Aluminum 7075-T6

Known for its excellent strength-to-weight ratio, 7075-T6 rivals even some softer steels in hardness. The 7075-T6 is widely used in the aerospace and military defense industries, common applications include aircraft accessories, tanks, high performance bicycles and more. Aluminum 7075-T6 is much more expensive than 6061 T6.

- Tensile strength: 434 – 580 MPa

- Elongation at break: 10-15%

- Elastic modulus: 69 – 76 GPa

- Hardness: 79-86 HRB

Aluminum 2024-T4

Aluminum 2024-T4 is a medium to high strength alloy with good fatigue resistance and fracture toughness. Aluminum 2024-T4 is not as strong as 7075-T6, but it is still suitable for aerospace applications. Common applications include aircraft fuselages, transportation vehicle parts and wings. 2024-T4 has poor corrosion resistance and is highly sensitive to thermal shock.

- Tensile strength: 200 – 540 MPa

- Elongation at break: 14 – 20%

- Elastic modulus: 71 – 73.1 GPa

- Hardness: 70 – 120 HB

Aluminum MIC 6

Aluminum MIC 6 has been specially developed for the production of stable, highly resistant sheets with impressive strain relief properties, excellent precision and high machinability. Aluminum MIC 6 is also non-polluting and non-porous, and is often used in electronics. The downside is that MIC 6 threads are not as strong as 6061 threads.

- Tensile strength: 166 MPa

- Elongation at break: 3%

- Elastic modulus: 71 GPa

- Hardness: 65HB

Aluminum 6082

Aluminum 6082 has similar properties to Aluminum 6061, but with higher strength, the highest strength of all 6000 series alloys, and excellent corrosion resistance. Aluminum 6082 is well suited to the construction industry and can be found in many bridges, towers and trusses. It is worth noting that aluminum 6082 is difficult to manufacture thin-walled parts.

- Tensile strength: 140 – 340 MPa

- Elongation at break: 6.3 – 18%

- Elastic modulus: 69 – 71 GPa

- Hardness: 35-56 HRB

Aluminum 5083-T6

5083-T6 aluminum is known for its exceptional performance in extreme conditions. This aluminum grade is very corrosion resistant in marine and chemical environments. The 5083 is not suitable for use in environments above 65°C. The 5083 has a wide range of applications in the cryogenic market. It is also ideal for marine applications, chemical applications, transportation vehicle parts, pressure equipment and more.

- Tensile strength: 210-270 MPa

- Yield strength: 125-150 MPa

- Elongation at break: 10-15%

- Maximum Temperature: 65°C

Conditioning and Surface Treatment of Aluminum

Heat Treatment: Aluminum is a softer metal than steel. Heat treatment refers to a process that changes the properties of metals on a chemical level and is an effective way to increase the hardness and strength of aluminum. 2xxx, 6xxx and 7xxx series aluminum can all be heat treated. 3xxx, 4xxx and 5xxx can only be increased in strength and hardness by cold working. Aluminum grades are suffixed with different parent names to identify the treatment employed. These are the names:

- F indicates that the material has not undergone any heat treatment.

- H indicates that the material has undergone some work hardening, whether concurrent with heat treatment or not. The number after "H" indicates the type of heat treatment and hardness.

- O indicates that the aluminum has been annealed, reducing strength and hardness but increasing toughness and ductility.

- T indicates that the aluminum has been heat treated, and the number after "T" identifies the details of the heat treatment process. For example, Al 6061-T6 is solution heat treated.

Finishing Services

Sandblasting

Sandblasting is a surface treatment process primarily used for aesthetic purposes. Aluminum parts are given a satin or matte finish by blasting tiny glass beads onto the surface using a high-pressure air gun. The main process parameters of sandblasting are the size of the glass beads and the air pressure used. This process is recommended only when the dimensional tolerances of the part are not critical.

Anodizing

Anodizing is an electrochemical process in which an aluminum part is immersed in a dilute sulfuric acid solution and an electrical voltage is applied to convert the surface of the part into a hard, non-electroreactive aluminum oxide coating that provides strong corrosion protection and enhances corrosion resistance. The overall appearance of the metal part.

Three types of aluminum anodizing are available from Protolabs:

Type I-Chromic Acid: Provides a whisper-thin but still durable coating. Commonly used for welded parts and assemblies, and as a primer before painting. Like all anodized surfaces, it is non-conductive.

Type II-Sulfuric Acid: Harder than Type I it offers an exceedingly durable finish. Usage examples include: carabiner hooks, flashlight handles, motorcycle parts, and hydraulic valve bodies.

Type III-Hard Anodize or Hardcoat: This is the thickest and hardest anodize available, and has a wide range of applications for parts and products in automotive, aerospace, heavy equipment, marine industry, general manufacturing, and military/law enforcement.

Coating

This involves coating aluminum parts with another material such as zinc, nickel and chrome. This is done to improve the part process and can be achieved through an electrochemical process.

Powder Coating

The powder coating process involves applying colored polymer powder to parts using an electrostatic spray gun. The part is then cured at 200°C. Powder coating increases strength as well as abrasion, corrosion and impact resistance.

Application of Various Grades of Aluminum Alloy

Aerospace/Aircraft

The following aluminum alloys have properties such as high strength, light weight, and efficient heat transfer, and are common in aerospace and aircraft applications.

- 1420

- 2004, 2014, 2017, 2020, 2024, 2080, 2090, 2091, 2095, 2219, 2324, 2519, 2524

- 4047

- 6013, 6061, 6063, 6113, 6951

- 7010, 7049, 7050, 7055, 7068, 7075, 7079, 7093, 7150, 7178, 7475

Marine / Offshore

Non-heat treatable alloys (5000 series) are preferred for marine applications due to their high corrosion resistance. Magnesium increases the strength and corrosion resistance of aluminum alloys and improves weldability. In high humidity, underwater and saltwater environments, 5000 series alloys are popular:

- 5052, 5059, 5083, 5086

- 6061, 6063

Automotive

For automakers, aluminum alloys are the first choice for body exterior parts and other components.

- 2008, 2036, 5083, 5456, 5754, 6016, 6111

- 5182, 5754, 6061, 6063

Bicycle

The following materials are preferred for bicycle frames and parts due to their light weight and high strength.

- 2014

- 6061, 6063

- 7005, 7075

Choosing the Right Aluminum Alloy for CNC Projects

If the designer chooses to use aluminum as the material of manufacture for the part, aluminum alloys 2024-T4, 7075-T6 and 6082 are best suited for high performance applications, while 6061 and MIC 6 can be used in most cases.

Because CNC machining is so versatile, it can be challenging for engineers to narrow down the list of materials that will fit a particular project. With decades of experience in rapid manufacturing, AN-Prototype’s team of expert designers and engineers can help every designer choose the right material more easily. AN-Prototype is committed to helping each customer innovate throughout the manufacturing process and achieve their desired results – material selection will meet all key requirements. Contact us today – turn your idea into reality as quickly as possible.