In the metal world, copper or “red metal”. Red copper and brass are often confused. Although both are versatile copper alloys, they are elemental metals because of their uniqueness, which will affect performance, service life, and even appearance. Copper and brass are two very different metals, with both similarities and significant differences. Choosing the right material will save a lot of money on the operation of this project, as it will directly affect the performance and production of the required parts.

Red copper and brass are our commonly used materials, in the machining of such materials should also consider its strength, weight, whether it has corrosion resistance, heat resistance and whether it is suitable for the field of work and so on. The purpose of this blog is to introduce the differences between red copper and brass, uses, advantages and disadvantages, machining methods and other information. Provide constructive advice for you to choose the right material machining.

Table of Contents

ToggleCopper vs Bronze vs Brass, difference?

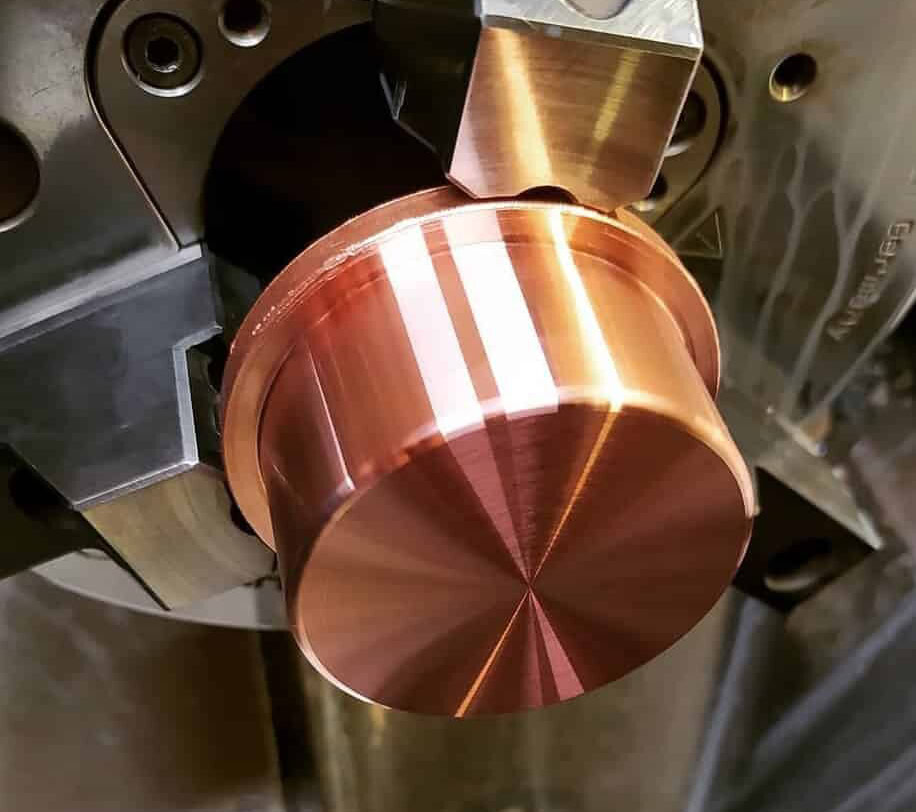

Copper is a pure elemental metal with a signature reddish-brown hue. Because copper has a special red appearance, manufacturers usually classify them as “red copper”. It is a naturally occurring metal (non-iron) with excellent thermal and electrical conductivity and can be used directly in a variety of compatible machining processes. It is commonly used in electrical wires and electronic products. Brass and bronze are typical alloys made by combining elements.

Bronze is a copper-based alloy, but its hardness is higher than that of pure red copper and contains other elements that can make it suitable for various fields of application. These metals have unique properties such as high electrical conductivity, high corrosion resistance, good thermal conductivity and excellent ductility. It can be adapted for different applications.

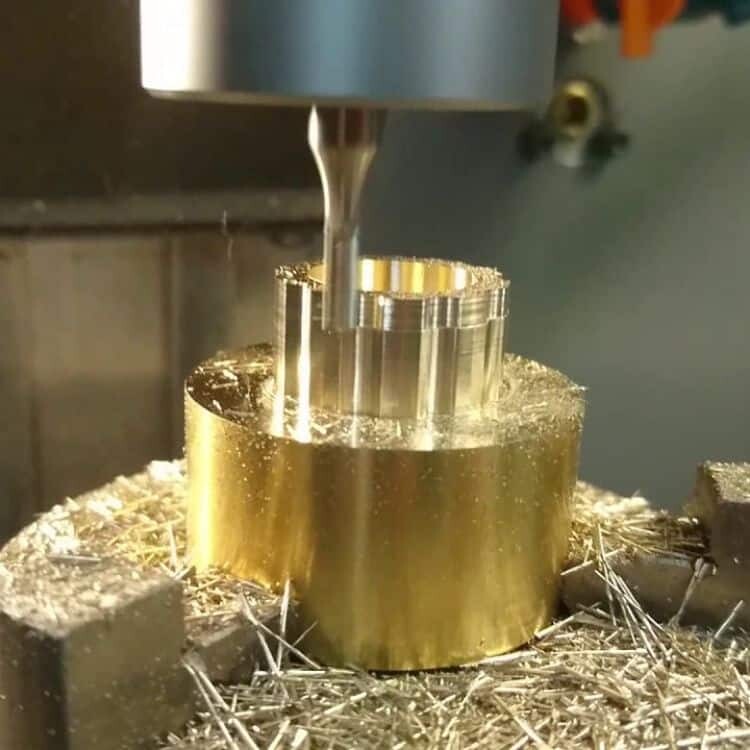

Brass is an alloy of copper and zinc, and its elements may include aluminum, silicon, iron, and manganese. Compared to other alternatives, this copper-based material is the cheapest option and has the highest zinc content. Brass materials have a low melting point and excellent formability. The content of copper and zinc determines the strength and appearance of brass materials. Some types of brass also contain small amounts of other elements, such as lead to improve workability or tin to improve corrosion resistance.

The higher the copper content, the dimmer the appearance of the brass material, and the higher the zinc content, the brighter the appearance of the brass material. The appearance of the very bright color is similar to gold, corrosion resistance, seawater corrosion resistance, higher strength, greater plasticity, can be used in Marine applications, decorative sculpture art, sanitation equipment and Musical Instruments, bearings of the preferred material. General brass has the characteristics of high strength, high hardness and strong chemical corrosion resistance, mainly used in the manufacture of valves and water pipes.

Copper and brass have different densities

The density of red copper is 8.96, and the melting point is 1083℃. It has good electrical conductivity and thermal conductivity, excellent plasticity, easy hot pressing and cold pressure machining, and is widely used in the manufacture of wire, cable, brush, electrocorrosion copper and other products requiring good electrical conductivity. The density of general brass is about 8.5-8.8g/cm3. Because the density of copper and zinc is different, the density of brass is related to the combination ratio of copper and zinc.

If your project requires a lightweight metal, then brass is a better choice than copper because they have a similar density, but brass is lighter than copper. Based on this, if your project needs lightweight metal, you should choose AN-prototype, AN-prototype has more than 15 years of machining experience, in terms of material selection, you can rest assured, maximize the savings of your production costs.

copper and brass are used differently

Red copper is suitable for manufacturing parts and products used in pipes, roofing, industry and electrical appliances. Here are some of them:

Architecture: Roof, door, spire, vault, spire, dome, water pipes, rain gutters, waterproof panels.

Marine: Bio-fuel resistant assemblies in submarines, liner of ship components, pipes, radiators, submarine components.

Telecommunications equipment: motors, electronic equipment, wire and cable, integrated circuits, printed circuit boards, radiators, heat exchangers, cathode-ray tubes, electromagnets, solar panels, turbine engines.

Brass looks similar to gold in various shades and has aesthetics and decoration. Its advantages are widely used. Common examples of this material include:

Musical Instruments: Brass is the most suitable metal for making musical instrument parts.

Accessories: Due to its unparalleled characteristics, it is suitable for making accessories for parts.

Decoration: jewelry decoration, door decoration.

Brass is widely used in locks, door handles, gears, valves, ammunition, pipes and electrical components. Brass is favored for its low friction properties and corrosion resistance. However, red copper also has its own advantages, so choosing An-prototype can solve the problem of material selection for you, and you do not need to consider it when choosing materials.

Price factor

Red copper is higher than brass. Red copper is the material for machining wires and cables. Brass is copper zinc alloy, the surface color is yellow, with the increase of copper content, brass color yellow slightly purple, zinc price is not higher than copper, so the price of brass is lower than that of red copper. Due to its superior performance, although the copper cost is higher, it can make the value of the product leap. Brass is a synthetic metal, and extracting and refining titanium requires specialized equipment and high-temperature processes – which will increase costs.

In machining, material consideration is an important factor. For example: cost, strength, durability and application requirements. Both copper and brass have unique advantages and challenges; It comes down to the material that best meets the needs of the project. In making this decision, material characteristics, manufacturing processes and production volumes must be considered. By carefully considering these details, An-prototype can make informed decisions and achieve the best results for your project.

Advantages of red copper

Corrosion resistance: Copper has a low reactivity, so it has excellent corrosion resistance.

Recyclability: Copper is highly recyclable and therefore an environmentally friendly choice.

High thermal and electrical conductivity: Copper is known for its excellent thermal and electrical conductivity, making it ideal for electrical applications.

Processability: Copper is soft, easy to forge, good ductility, easy to process and make a variety of parts.

Advantages of brass

Durability: Brass has good corrosion resistance, ensuring its long-term durability and performance.

Antibacterial properties: The high copper content in brass makes it suitable for sanitation and water filtration systems.

Brass is attractive, and the finished product can be polished and polished to achieve a variety of textures and glossiness to improve aesthetics.

FAQ

Which is better, copper or brass?

Which metal is better depends on the use. Copper has good electrical conductivity, and brass has excellent workability.

How to reduce the cost problem when choosing?

It is worth mentioning that we have a wide variety of materials in stock. If you are still worried about the suitability and cost of materials, of course, you can choose AN-prototype, AN-prototype has more than 15 years of CNC machining experience, can choose the right material for you to process, so as to reduce your production costs. The products produced have excellent quality, so that you have no worries.