EDM Machining is an electrical discharge reduction manufacturing process and a non-contact processing method that uses thermal energy rather than mechanical force to remove material from the workpiece. EDM is only suitable for conductive materials such as titanium, steel, aluminum, nickel and brass. The processing cost, processing time and debugging equipment cost of EDM are relatively high, but EDM can do the process that CNC milling machines cannot do. The purpose of this blog is to introduce the history of EDM processing, advantages and disadvantages, processing process, type and other information, to provide constructive advice for you to choose the right EDM processing service.

Table of Contents

ToggleWhat is EDM Machining?

EDM Machining can achieve precision tolerances in the ± 0.005 mm range, especially suitable for machining complex or fine injection molds and metal parts with sharp internal angles, curves, holes, engraving and other features. EDM is unique in that it does not use sharp tools to remove material like traditional CNC machining. Instead, EDM uses electricity and heat to remove material, which is why it is called EDM. The EDM is operated without physical contact with the workpiece being machined, using electrical discharge close to 8000º C to 12000º C to remove excess parts of the material. Because the material to be cut after processing is stimulated by high temperatures into carbon deposits, immersed in the electric fluid, these particles are safely washed away from the electrode and the surface of the workpiece.

History of EDM Machining

In the 18th century, the British scientist Joseph Priestley discovered that electrical discharge can corrode materials on electrodes, and he continued to use electricity to do experiments, but did not know what purpose to do the experiment, and finally gave up the matter. EDM was invented in the 20th century when two Soviet scientists, B. Lazarenko and N. Lazarenko, used electric currents to process conductive materials. And EDM in the 20th century, the rapid development of science and technology in the era of continuous innovation, EDM process increasingly mature and fine workmanship, at the same time for a variety of very hard materials processing EDM precision can be controlled more accurately, easier to operate.

What is the EDM Machining process?

The first step is to place the conductive metal workpiece on the EDM spark machine operating fixture table.

The second step then uses the fixture to clamp the workpiece, next tests the horizontal state of the workpiece and the spark head, and places the tool on the vertical line slide for accurate positioning. Tools emit sparks when they approach the workpiece without touching it. If the tool is too far from the workpiece, it will not produce sparks. If it is too close, then it is possible that the workpiece may fuse together. When the workpiece level is offset, then the entire workpiece being machined is distorted (the size is also wrong). Generally, the discharge gap should be controlled in the range of 1 ~ 100μm, which is related to the pulse size of the discharge current.

The third step is to start debugging the equipment after the machinist calibrates the position, input the position, size, shape and other information you want to process on the computer. When the program is set up, the EDM spark machine can start working. The molten metal cools rapidly in water to form carbon deposits, which the deionized water will wash away. Carbon accumulation to a certain extent can trigger an early warning system, and too much carbon accumulation can adversely affect the outcome.

Types of EDM Machining

There are three kinds of EDM: discharge machining, wire-cut EDM and borehole EDM.

Electric discharge machining is one of the four popular processing technologies, and milling, turning and grinding keep pace. In general, it is suitable for manufacturing complex molds with fine cavity characteristics. With CNC milling machining principle is completely different, EDM refers to a certain medium, through the pulse discharge between the tool electrode and the workpiece electrode, the workpiece machining method.

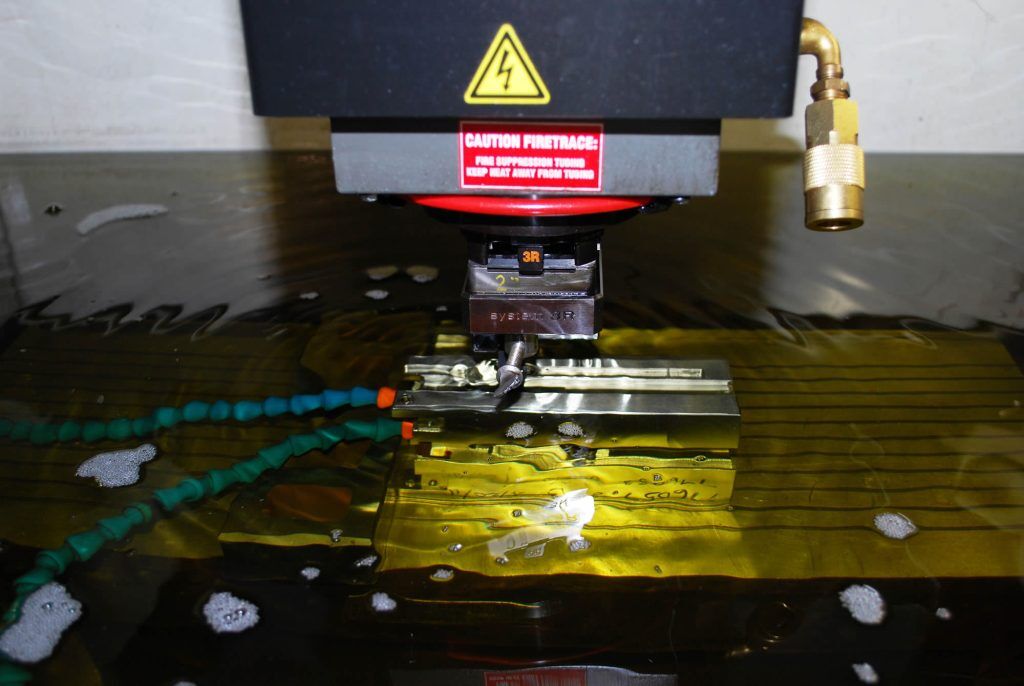

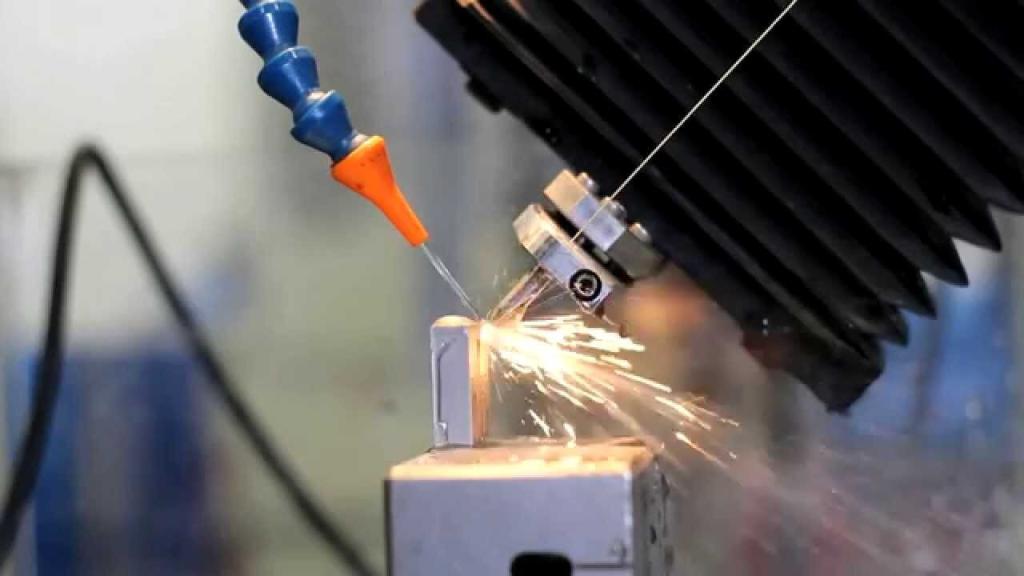

During Sinker EDM, the tool and the workpiece are not in contact, but rely on the pulsed spark discharge continuously generated between the tool and the workpiece, and use the local and instantaneous high temperature generated during discharge to gradually erode the metal material. Because there are visible sparks in the discharge process, it is called EDM. Tool electrode commonly used good electrical conductivity, high melting point, easy to process electrical corrosion resistant materials, such as copper, graphite, copper tungsten alloy and molybdenum. In the process of machining, the tool electrode also has a loss, for less than the amount of corrosion of the workpiece metal, close to no loss. As the discharge medium, the working liquid also plays the role of cooling and chip removal in the process of processing. Commonly used working fluids are: kerosene, deionized water and emulsion, etc., because they are characterized by low viscosity and stable performance.

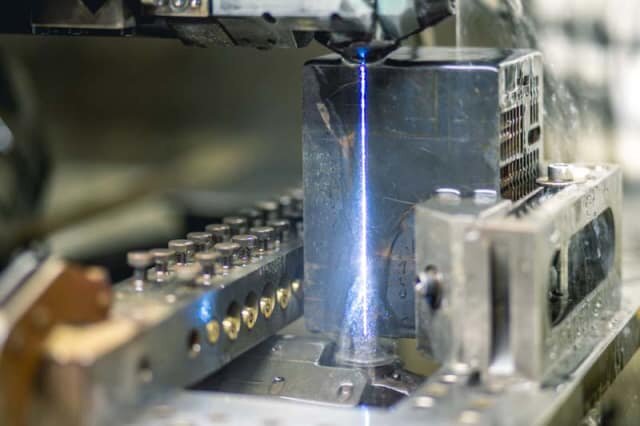

Wire-cut discharge machining

Wire-cut EDM is a non-contact reduction manufacturing process that uses charged thin wires and dielectric fluids to cut metal parts into the desired shape. Metal workpieces are cut through brass wires with diameters ranging from.004 inches to.012 inches (.10 mm to.30 mm) following a precisely controlled path. The diameter of the wire can be larger or smaller. When energized, the wire quickly rises to the required voltage and corrodes the workpiece through discharge. The resulting debris is cooled by deionized water and washed away. Wire-cut EDM process is not sensitive to the hardness of the workpiece, compatible with tungsten carbide, rare carbide.

The wire-cut EDM process must be carried out in a container filled with deionized water. Depending on the application, the materials of the wire include copper, brass, tungsten, molybdenum, coating (galvanized and diffusion annealed) and steel core wire. It is worth noting that no matter what type of wire, there is only one service life, and only the waste value is left after use. AN-Prototype is investing in five high-spec Mitsubishi and Sodick WEDM machines in 2021 with complex parts manufacturing up to 1300 mm x 1000 mm x 670 mm. As a wire-cutting service specialist, we have experience in manufacturing keyways, gears, splines and other feature parts. Typical tolerances for parts are up to ±0.000001 “.

Drilling EDM Machining

Drilling EDM is the first EDM technology developed, which is suitable for machining parts with holes smaller than 5mm. Drilling EDM processing is also not limited by the hardness of metal materials. The tool electrode material can be steel, cast iron or copper. An-prototype’s Sodick is a high-speed drilling machine that is widely used to drill and cut holes. Aircraft engines in the aerospace sector and gas turbine blades in the energy production sector, as well as impellers in medical and scientific equipment, need to drill cooling holes. In order to form a layer of cooling air on the turbine blade and blade surface, to prevent it from overheating. The Sodick is one of the perfect solutions when you need to drill very long and straight small holes on workpieces with sloping surfaces that are hard to reach. Drilling EDM allows blind and through-hole drilling, and can drill smooth holes without burrs on parts where CNC milling and turning cannot achieve geometric shapes.

Application of EDM Machining ?

The application of EDM is very wide, and it can show its unique advantages in various industries. In the manufacture of household appliances, EDM can process complex parts to meet the increasingly refined needs of household appliances.

EDM plays an irreplaceable role in the manufacture of key components of chassis and engine structures in the automotive industry, ensuring the safety and reliability of vehicles. In addition, in the field of aviation and aerospace, EDM processing can process high-hardness conductive materials and manufacture parts with complex cavities, meeting the requirements of high precision and high reliability in the aerospace field. At the same time, EDM also plays an important role in industries such as shipping, medical inspection, electronics and mechatronics, providing strong support for the innovation and development of various industries.

It is worth mentioning that the EDM processing not only ensures the quality of the workpiece, but also the surface of the workpiece after processing is smooth without burrs, and there is no need to carry out cumbersome post-processing, which greatly saves labor costs. In addition, EDM is also very suitable for high-volume custom manufacturing needs, such as mold manufacturing and prototyping, providing an efficient and reliable solution for the mass production of enterprises.

Advantages of EDM Machining?

Precision: EDM has the unique advantage of accurately cutting complex shapes and depths, while traditional processing techniques are limited and cannot reach this level of processing. At the same time, EDM can easily achieve extremely tight tolerances in the ± 0.005 mm range.

No damage to materials: The non-contact nature of EDM enables it to form small parts with fine features or thin walls, and there is no risk of deformation, damage or breakage of the machined parts.

No surface treatment: EDM achieves a high quality surface finish without any tool marks or burrs and saves labor by manually re-treating surface problems later. However, if the EDM speed is adjusted too quickly, the processing method may produce a fine sandblasted texture.

Disadvantages of EDM Machining?

High cost: Due to the high tool wear rate, the electrode must be periodically checked and replaced, so the accessories cost of the EDM process is high. At the same time, because the debugging equipment takes a long time, and because EDM is a non-traditional processing method, the time debugging cost and the time cost of processing are also relatively high. While EDM can be costly for small series production, EDM is more cost-effective as production scales up and the increased expenses are spread over numerous components.

High power consumption: EDM is an energy-intensive manufacturing process. Because it relies on constant current, it consumes higher power, which increases costs and has a greater impact on the ecological environment. Therefore, compared with EDM, alternative processing methods that consume less power and have less impact on the environment are becoming the first choice.

Incompatible with non-conductive materials: EDMs are compatible with a wide range of metal materials, including the hardest metals, as long as they are electrically conductive (titanium, steel, aluminum, nickel and brass, etc.). But it’s limited to conductive materials, which means it doesn’t work with any plastics, ceramics, or composites. At the same time, because the metal will expand when heated, this may affect the metallurgical properties of the workpiece, (so the cooling of the processed object is also particularly important).

Conclusion

EDM spark machine, after hundreds of years of development, from the unknown equipment to the important role in the production of drilling, we can imagine how difficult the development process of EDM. Now, what EDM brings us is that complex things can be done simply, and don’t need to be too complicated. In the processing, we can choose according to demand, not only for the pursuit of speed and production, EDM is for the pursuit of high quality and production, which is the original intention of the manufacturing industry, but also the mission of An-prototype.

FQA

Q1 EDM machining or CNC machining?

No matter how many. However, as long as it involves right angles, small holes, precision holes and parts with complex cavities, EDM can be selected, although the cost is high, but compared with CNC machining, CNC is difficult to achieve this processing technology of drilling parts in complex cavities, when we give the time cost to those parts that need to be processed, then we can figure out, We use EDM machining is much more cost-effective than CNC machining. An-prototype is a company with more than 15 years of professional EDM machining and CNC machining experience, and there are many successful cases.

Q2 How to save costs?

It is recommended to manufacture parts in small batches. A mechanic needs time to debug a machine before machining a part, and once the machine is ready, the same process can control the manufacture of hundreds, thousands of parts, or even more. If you only need one or a few custom parts, the cost will be high. Because the labor cost of trained and skilled mechanics is very expensive. If the number of a part reaches thousands, this will greatly reduce the labor cost shared by a single part, or even negligible. In short, the higher the number of parts manufactured, the lower the corresponding cost will be.

Q3 Will drawings be leaked?

Your drawings and information are the top secret of AN-Prototype. For each order before starting, An-prototype recommends signing the NDA.

Q4 Customization parts processing time?

According to the complexity and tolerance requirements of parts, AN-Prototype can process 100pcs in three days at the earliest, and complete quality inspection in one day.

Q5 How to ensure that the machined parts are perfect?

An-prototype quality inspection engineers will use CMM coordinate measuring instrument, secondary element, height vernier caliper, screw plug gauge, screw pin and other professional measuring instruments to test your product again, after the test is completed, the product will be packed and shipped together with the full-size quality inspection report, to ensure that the quality of the product delivered to you is intact, beyond your expectations.