Polyoxymethylene (POM), commonly known as acetal or its brand name Delrin®, is an engineering plastic. Acetal (acetal), polyoxymethylene (POM), polyacetal (polyacetal), polyoxymethylene, these are its names, and the common ones are black and white. In the description that follows, the various names of the POM will appear randomly. Although POM is opaque in nature, it is available in a variety of colors. POM has high mechanical strength and rigidity, good sliding properties (low coefficient of friction), and excellent wear resistance. Since acetal absorbs little water and has excellent dimensional stability, it is an excellent choice for complex shapes and precision machined parts. However, it is unstable and easily degrades under acidic conditions and high temperatures. Since its molecules contain a large amount of oxygen, it is difficult to impart flame retardancy, and its continuous use temperature ranges from -40°C to about 120°C. There are two common variants of POM, homopolyacetal POM-H and copolyacetal POM-C, POM-H is greater than POM-C in terms of hardness and stiffness, and the melting point of POM-H (172-184°C) is more The temperature is about 10°C higher than that of POM-C (160-175°C), the density is 1.410-1.420g/cm3, and the crystallinity is 75-85%. There are also some modified polyoxymethylenes with higher melting points.

Table of Contents

TogglePOM manufacturing process

POM was first discovered by German chemist Hermann Staudinger in 1920 and commercialized in 1956 by DuPont (the original manufacturer of Delrin® plastic). Like all other plastics, POM is made by distilling hydrocarbon fuels into lighter groups. The “distillates” can then be combined with other catalysts through polymerization or polycondensation to produce finished plastics.

To make acetal homopolymers like Delrin®, anhydrous formaldehyde must be produced by reacting aqueous formaldehyde with an alcohol to form hemiformal. Hemiformal is then heated to release formaldehyde, which is polymerized by anion catalysis. The resulting polymer is stable when reacted with acetic anhydride to form a polyoxymethylene homopolymer.

Delrin® Plastic Properties and Mechanical Specifications

Delrin® can also be used in general industrial equipment such as bearings, gears, pumps and instrumentation. The excellent mechanical properties of acetal make it extremely versatile, offering a unique combination of properties not found in most metals or other plastics. Delrin® plastics are strong, rigid, and resistant to impact, creep, abrasion, friction, and fatigue. It is also known for its excellent dimensional stability during high-precision machining. Acetal is also resistant to moisture, gasoline, solvents and many other neutral chemicals at room temperature. From a design standpoint, parts made from extruded POM naturally have a smooth surface finish.

Because acetal is compatible with CNC machining, injection molding, extrusion molding, compression molding, spin casting, and more, product teams have the freedom to choose the manufacturing process that best fits their budget and needs. However, it is worth noting that Delrin® plastics are often difficult to bond.

Acetal material properties vary by formulation, but the mechanical properties of one of the most popular formulations, Delrin® 100 NC010, include:

- Yield strain: 26%

- Yield stress: 71 MPa

- Density: 1420 kg/m3

- Water absorption: 0.9%

- Tensile modulus: 2900 MPa

- Normal linear thermal expansion coefficient: 110 E-6/K

Delrin® does have some limitations. For example, although Delrin® is resistant to many chemicals and solvents, it is not very resistant to strong acids, oxidizing agents or UV radiation. Prolonged exposure to radiation can distort color and cause parts to lose strength. Additionally, flame ratings are not readily available for this material, which limits its usefulness in certain high-temperature applications.

Why Delrin® Plastic?

Despite these limitations, there are many reasons to choose acetal over other materials. Compared with other plastics, acetal has better creep, impact and chemical resistance, better dimensional stability and higher strength. It also has a lower coefficient of friction.

Acetal also outperforms certain metals. Parts made from this material have higher strength-to-weight ratios, better corrosion resistance, and offer more opportunities for part integration. With acetal, you can make thinner, lighter parts faster and cheaper than comparable metals.

Delrin® plastics are found in nearly every major manufacturing sector. In the automotive industry, common applications include heavy-duty gear, fuel system components, speaker grills, and safety system components such as seat belt hardware. Delrin® can also be used in general industrial equipment such as bearings, gears, pumps and instrumentation.

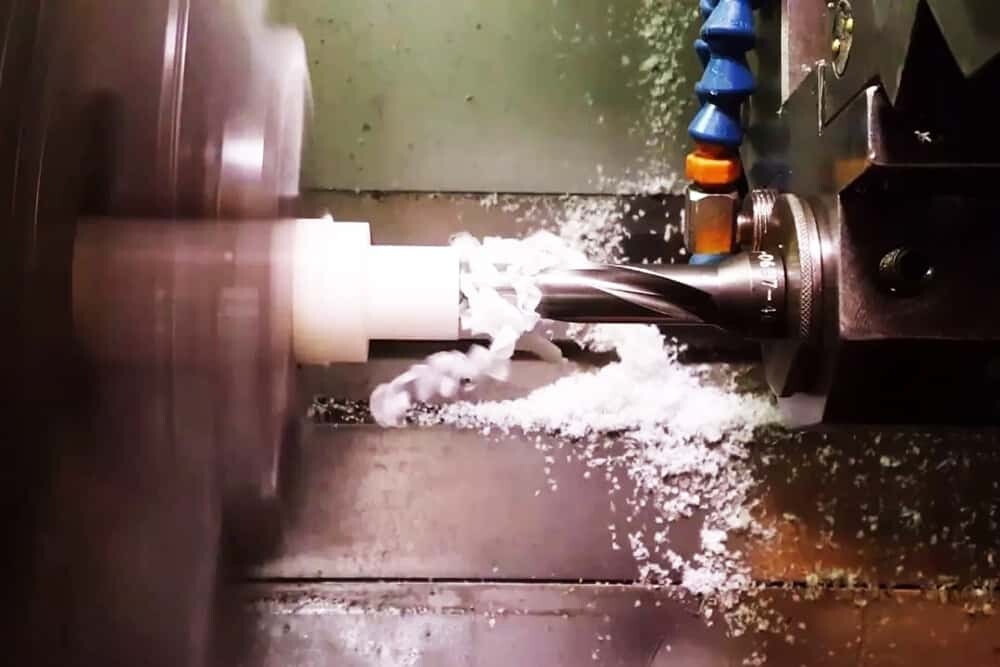

Advantages of CNC machining POM

Electrical Characteristics

POM has excellent thermal insulation properties, coupled with its excellent mechanical strength, POM is a very suitable material for electronic components. POM can also withstand significant electrical stress, making it suitable for use as a high-voltage insulator. Its low moisture absorption also makes it an excellent material for keeping electronic components dry.

Mechanical strength

POM is very hard, very ductile, and has a lower density than metals. Making it suitable for lightweight parts that need to withstand high pressure.

Anti-fatigue

POM is a very durable material with excellent resistance to fatigue failure in the temperature range of –40°C to 80°C. In addition, its fatigue resistance is less affected by moisture, chemicals or solvents. This property makes it an ideal material for parts that need to withstand repeated impact and stress.

Impact resistance

POM can withstand instant impact without failure, mainly due to its very high toughness, and specially treated POM can provide greater impact resistance.

Good dimensional stability

Dimensional stability measures a material’s ability to maintain its normal dimensions after exposure to pressure, temperature, and other conditions during CNC machining. POM does not deform during CNC machining, is ideal for machining, and can achieve precise tolerances.

Frictional properties

Moving mechanical parts often require lubrication to reduce the friction they create as they rub against each other. CNC machined POM parts are inherently smooth and do not require lubrication. This feature can be used as part of machinery where external lubricators may contaminate the product, such as food processors.

Sturdiness

The high tensile strength and durability of POM make it a suitable material for high stress applications. POM is very strong and is often used as a replacement for steel and aluminum alloys.

Moisture-proof

Even under the most humid conditions, POM absorbs very little water. This means it maintains structural integrity even in underwater applications.

Creep resistance

POM is a very tough material that can withstand a lot of stress without failure. This exceptional durability makes it the material of choice for parts in many industries.

Electrical Iinsulation

POM is an excellent insulator. Due to this property, it is used in many electronic products.

Disadvantages of CNC machining POM

Low Adhesion

Due to its chemical resistance, POM does not respond well to adhesives, making it difficult to bond.

Flammable

POM is not self-extinguishing and will burn until oxygen is gone. Fighting a POM fire requires the use of a Class A fire extinguisher.

Thermal sensitivity:

CNC machining of POM at high temperatures can cause deformation.

Problems easily encountered in CNC machining POM

Generally speaking, the main problems encountered by CNC machining POM are deformation and cracking. There are also two kinds of common cracks here, one is direct cracks during CNC machining, and the other is hidden cracks (usually caused by internal stress). Slowly cracking after CNC machining is frustrating.

If the selected POM material is not good, or the dimensional tolerance requirements are relatively high, it is recommended to anneal after rough machining to eliminate its internal stress, which can greatly reduce the deformation after finishing. There will be certain differences between different manufacturers or grades of POM materials. The following process parameters are for reference only:

After rough machining, oil bath annealing (in hot oil) or air bath annealing (in an oven) is performed. Adjust the annealing temperature, which is generally 10-20°C (about 140-150°C) lower than the heat distortion temperature of the product. For oil bath annealing, increase the annealing time by 40-60 minutes for every wall thickness of 5 mm, for air bath annealing, increase the annealing time for 20-30 minutes for every wall thickness of 5 mm, and cool naturally to room temperature after completion.

Another “earth method” annealing method (annealing temperature 100°C)

When the ambient temperature of the CNC parts is lower than 80°C, put them in boiling water for 5-6 hours after rough machining, and cool to room temperature naturally. With enough time, natural aging methods can also be used. After rough processing, it should be naturally placed at room temperature (preferably constant temperature) for about a week.

Common deformation causes and countermeasures of CNC machining POM

First of all, it is best to ensure that the blank size of the workpiece is consistent during CNC machining, which is more conducive to grasping relatively consistent deformation and controlling the tolerance within a relatively close range.

1. Clamping causes deformation

POM material deforms when clamped, and returns to its original state when loosened. At this time, you can consider changing the clamping form in order to increase the contact surface of the workpiece. For example, the bench vise pads things, fixes them with glue, and so on. For larger sheets, vacuum suction cups can be used, but the blank needs to be flat. It is recommended to fix one side with glue before sweeping, and then fix the smooth surface with a suction cup for rough machining.

2. Cutting heat causes deformation

POM materials have poor heat resistance and are sensitive to heat, and are easily deformed due to insufficient cooling during processing. First of all, the tool must be sharp so that the heat generated during cutting is relatively small. Secondly, the amount of cutting can be reduced, cutting can be divided into multiple times, and the coolant can be increased. The purpose is to minimize heat generation or quickly remove heat generated during cutting.

3. Elastic deformation

POM material has high elasticity. When cutting, the part in contact with the tool deforms inward due to the elasticity of the material. When the tool moves away, the part that is cut and pressed will deform by a certain amount. At this time, it is necessary to perform multiple tool compensation adjustments according to the actual cutting effect. Multiple cycle cutting with small cutting amount during processing can reduce the dimensional deformation caused by material elasticity.

4. Internal stress deformation

Since the thermal expansion coefficient of engineering plastics is larger than that of metals, when the machining allowance is large, deformation will occur due to the elimination of internal stress. First, proper selection and processing of materials (as above). Secondly, when the amount of material removal is relatively large, try to place as thick a material as possible, control the margin, and use symmetrical processing (whether the part design itself is reasonable or not is actually critical) to offset stress and deformation caused by processing.

Once complete, attention should also be paid to temperature control during transfer and storage. If possible, maintain the temperature to prevent the parts from deforming due to temperature changes. At the same time, remember to protect the surface to avoid scratches, etc.

Common Causes of Cracking

The aforementioned degree of deformation is more prone to cracking, but this is only part of the reason. There are several reasons why POM materials crack during operation:

- 1. The amount of knife eating is too large during CNC machining;

- 2. Directly use a larger drill bit to drill holes, the cutting force is too large, and it is easy to crack;

- 3. When CNC machining deep holes, the drill bit does not retreat repeatedly to remove chips, the chips are not discharged sufficiently, and extrusion cracks appear;

- 4. Insufficient cooling, insufficient cooling of drilling holes, resulting in cracks due to excessive cutting heat and cutting force;

- 5. If the feeding speed is too fast, the internal stress of the POM rod will cause cracks;

- 6. When drilling, the cutting edge of the drill bit is worn out. If the drill bit is not repaired in time, the hard drill will cause cracking.

Selection of CNC machining methods

CNC milling

We have 3-axis/4-axis/5-axis machining capabilities to suit your every use and need for Delrin machined parts, allowing us to handle complex CNC machined POM parts while maintaining high precision, precision, flexibility and consistency sex. We can also provide CNC milling and CNC turning for other needs in the production of acetal parts. If you are considering using POM material to make your desired CNC products.

CNC turning

Cooling is required during CNC machining to reduce wear and conduct heat to prevent melting. It is recommended to use compressed air cooling or solid lubrication first, and then use coolant. The speed should not be too fast, and the feed and engagement should not be too large. The rake angle and relief angle of the tool can be slightly larger, and the cutting edge must be sharp. The front angle of commonly used high-speed steel turning tools is about 25°~40°, and the rear angle is about 10°~20°. The clamping force of the chuck should be as small as possible.

CNC drilling

Do not directly drill with a large drill bit, it is recommended to drill a small hole first and then ream at a low speed. The drill bit must be kept sharp, and you can refer to the following drill bits: apex angle 60°~90°, helix angle 10°~20°, rake angle 0°, back angle 10°~15°. When drilling, the force in the feed direction should not be too large, and the tool should be retracted in time (generally 5~6mm deep) for chip removal and cooling. For drilling through holes, the feed rate should be reduced when drilling quickly so that the drill does not push the material away in the axial direction.

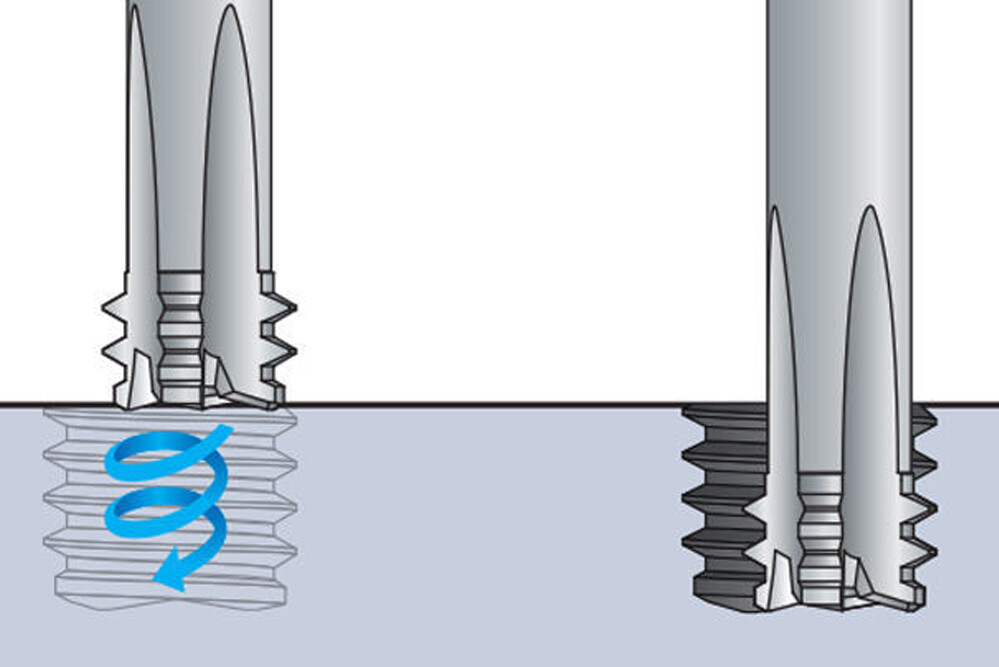

CNC threading

Except for different tools, they are generally the same, that is, deformation should be avoided when clamping, the tool should be kept sharp, the feed rate should be small, and the cooling should be sufficient.

Application of CNC Machining POM Parts

1. Automobile industry

In the automotive sector, POM plastics are used in fuel system components, window regulators, and various interior and exterior components.

2. Electrical and electronic components

The electrically insulating properties of POM make it suitable for the production of connectors, switches and insulating components in electronics.

3. Consumer Goods and Appliances

POM plastics are widely used to make zippers, buckles, handles and other components for consumer goods and appliances.

4. Medical devices

In the medical field, POM is used to produce surgical instruments, drug delivery systems, and other medical devices due to its biocompatibility.

5. Engineering and industrial parts

The mechanical strength and wear resistance of POM make it an excellent choice for a wide variety of engineering and industrial components.