Best CNC Machining Services In China

Services:3Axis. 4Axis. 5Axis Best CNC Machining Services, CNC Milling, CNC Turning, EDM Machining, Wire EDM Machining

Tolerance : +-0.05mm(Custom Available)

Roughness : Ra0.2-Ra0.8(Custom Available)

Drawing format : CAD file (dwg, dxf, pdf, etc.), 3D File (step, stp, etc), drawing design.

Surface treatment: Plating, Brushing, Polishing, Anodizing, Sandblasting, Knurling, or customer’s requirements

AN-Prototype’s CNC machining capabilities

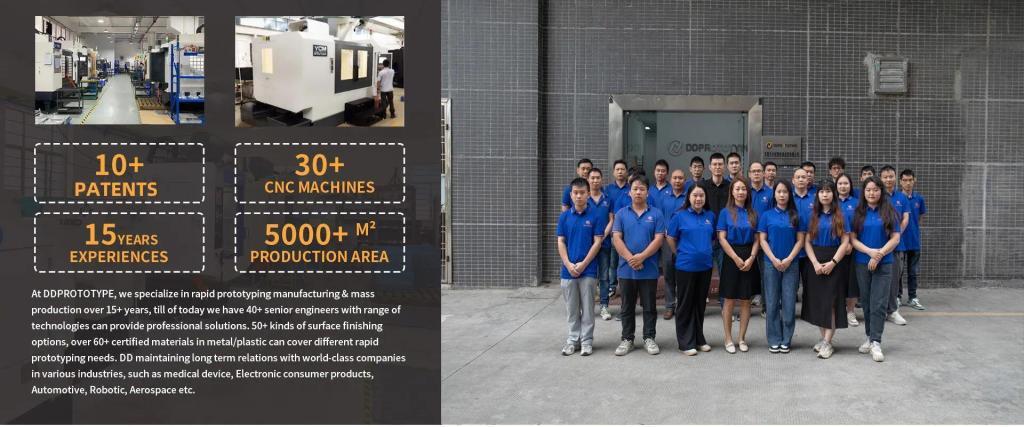

For more than ten years, AN-Prototype has been committed to providing customized CNC machining precision parts services. Our precision CNC machined parts are manufactured to the tightest tolerances and are durable even in the most extreme conditions. AN-Prototype’s state-of-the-art in-house CNC machines and expert programmers and machinists ensure every CNC project meets the highest industry standards and exceeds customer expectations. If you are searching for “the best CNC machining company near me”, then AN-Prototype is the one you can trust!

| High Quality OEM CNC Machining Services Factory | ||

| Services | CNC Milling,CNC Turning, Laser Cutting, Bending, Spinning, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection Molding,Vacuum Casting. | |

| Materials | Metal | Aluminum: 2000 series, 6000 series, 7075, 5052, etc. |

| Stainless Steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc. | ||

| Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc. | ||

| Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper, etc. | ||

| Titanium: GradeF1-F5 | ||

| Rare Material:CoCr28Mo6,Cobalt Chrome Molybdenum,Ceramics,Monel,Inconel. | ||

| Plastic | Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc. | |

| Finishing Services | Anodizing, Bead blasted, Silk Screen, PVD Plating, Zinc/Nickel/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc. | |

| Tolerance | +/-0.002~+/-0.005mm (2D Drawing Requirements). | |

| Surface Roughness | Min Ra 0.1~3.2 (2D Drawing Requirements). | |

| Drawing Accepted | STEP, IGS, X-T, AutoCAD(DXF, DWG), PDF, or Samples | |

| Lead Time | 1-2 weeks for samples, 3-4 weeks for low volume manufacturing or mass production | |

| Quality Assurance | ISO9001:2015, ISO13485:2016, SGS, RoHs, TUV | |

| Payment Terms | Trade Assurance, TT/ PayPal/ WestUnion | |

| Shipping | DHL,FEDEX,TNT,Ocean Shipping | |

CNC milling

Milling utilizes rotating tools to cut and remove chips from a workpiece through physical contact. This technology is used for different functions such as threading, grooving and chamfering. It can produce complex and complex designs on a single milling center. The precision of CNC milling is unparalleled, with tolerances as tight as +/- 0.005 mm. There are various sub-types of CNC machining services such as face milling, form milling, gear milling, copy milling, and surface milling. These subtypes can be milled transversely, axially, or a mixture of both. Milling processes can be used on different metals (steel, aluminum and brass) and plastics (nylon, POM, HDPE, ABS, polycarbonate, etc.)

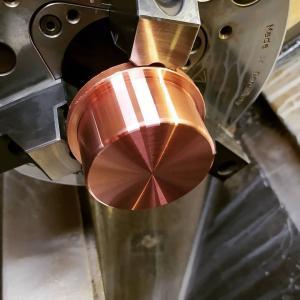

CNC turning

CNC turning, also known as CNC lathe, is used to make cylindrical parts such as shafts or bushings. The metal part rotates while the CNC controls the cutting tool’s axial movement along the sides and back and forth. Material around the metal is removed, producing the desired shape and diameter. Turning can be done using a fixed head CNC machine or a sliding head CNC machine. The latter serves to reduce final price and production time.

CNC drilling

This CNC machining service is mainly used to create cylindrical holes in workpieces using multi-point drills. Vertical and inclined drilling can be achieved using this method. Vertical drilling simply uses a CNC machine to insert a rotating drill bit into the workpiece, while angle drilling can get a little more complicated. For angle drilling, clamping devices and specialized machining configurations are required. Tapping, reaming, and countersinking are some of the operations that can be performed using CNC drilling.

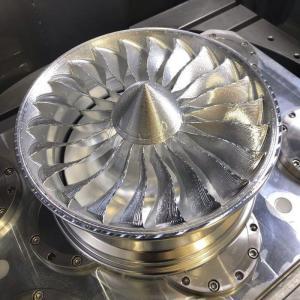

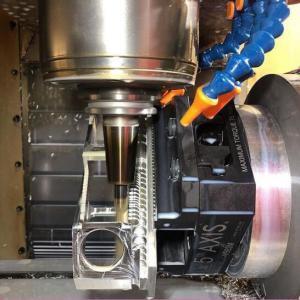

CNC multi-axis machining

CNC multi-axis machines have multiple spindles placed in drums. This drum constantly changes position and rotates horizontally, completing many operations at the same time. Without multiple spindles to divide the work, these operations must be performed one after another to complete the desired product. Now, each time the drum rotates, a portion of the operation is completed. Using multi-axis CNC machining services or tools is more efficient and often more cost-effective than using multiple CNC machines.

Benefits of CNC machining

CNC machining offers high precision and repeatability, ensuring that the first part is the same as the last.

CNC machining has short lead times and production times, getting your parts to you faster. This helps reduce costs.

AN-Prototype’s ultra-precision CNC machines allow us to produce complex parts with extremely tight tolerances (+/-.0005) and superior surface finishes.

CNC machining is compatible with a variety of materials, from metals to engineering plastics. These include specialty plastics that are difficult to process or cannot be processed by other manufacturing methods, such as injection molding and 3D printing.

CNC machining is cost-effective for both small and large production runs, allowing you to manufacture the right amount of parts without going over budget.

How to choose the best CNC machining service?

If you are considering the best CNC machining services, it is important to understand the different types of CNC machines and their capabilities. The best approach is to find a supplier with the specific machine tools you need. Here are four factors to consider when choosing the best CNC service:

– Tool type: Not all machines are capable of performing certain types of machining. For example, some machines are better suited for milling, while others are better suited for turning.

– Capabilities: View a supplier’s overall machine capabilities, not just their CNC machine inventory. Some suppliers may have limited machining capabilities but offer a wide range of services, such as design engineering and CAM programming.

– Service Level: Be sure to ask about the level of service provided by the provider. This includes quote turnaround time, project start date, completion date and any warranties or guarantees associated with the service. You also need to be aware of any additional fees that may apply.

Quality is always AN-Prototype’s top priority

Whether you choose CNC milling services, turning, lathing, or any other CNC precision machining service, you can always count on AN-Prototype to perform work that will exceed your quality expectations. As an ISO 9001 and AS9100 certified company, we adhere to the highest quality standards in the CNC machining industry. We have implemented the strictest quality control procedures in every aspect of our operations to ensure complete customer satisfaction.

Related products

-

CNC Machining Parts

Rapid CNC Machining Prototype In China

-

CNC Machining Parts

CNC Lathe Machining Parts Services In China

-

CNC Machining Parts

3Axis 4 Axis 5 Axis CNC Machining Parts

-

CNC Machining Parts

5 axis CNC Machining Services Turning Parts