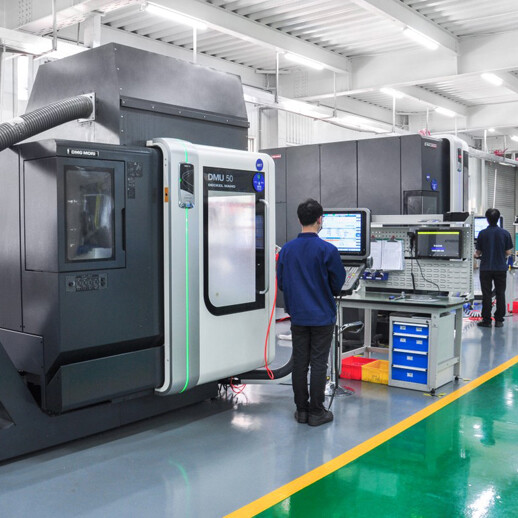

Custom Online CNC Machining Service In China

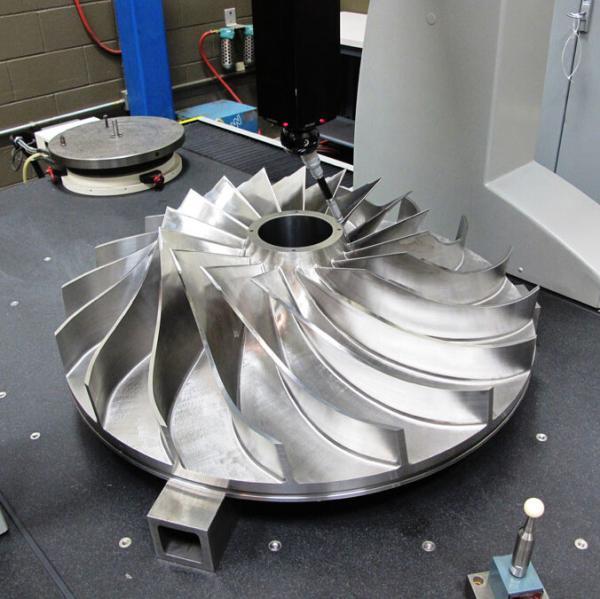

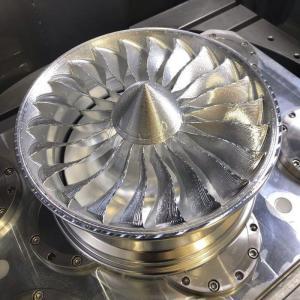

Services:3Axis. 4Axis. 5Axis CNC Machining Services, CNC Milling, CNC Turning, EDM Machining, Wire EDM Machining

Tolerance : +-0.05mm(Custom Available)

Roughness : Ra0.2-Ra0.8(Custom Available)

Drawing format : CAD file (dwg, dxf, pdf, etc.), 3D File (step, stp, etc), drawing design.

Surface treatment: Plating, Brushing, Polishing, Anodizing, Sandblasting, Knurling, or customer’s requirements

AN-PROTOTYPE CNC Machining Sercices Capacity

| CNC Machining Center | 3 / 4 / 5 axis CNC Machining Center | 40+ CNC Machines |

| CNC Turning | φ0.5 – φ300 * 750 mm | DIN-2768-Fine +/-0.005 mm |

| CNC Machining | 1270×508×63 mm(max) | DIN-2768-Fine +/-0.005 mm |

| CNC Stamping | 1000 * 1000 mm(max) | DIN-2768-Fine +/-0.005 mm |

| Drawing Format | IGS,STP,X_T ,DXF,DWG , Pro/E, PDF | |

| Quality Inspection | Measurement Instrument, Projector, CMM, Altimeter, Micrometer, Thread Gages, Calipers, Pin Gauge etc. | |

Material Available

| Stainless Steel | SS201,SS301, SS303, SS304, SS316, SS416 etc. |

| Steel | mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45# etc. |

| Brass | HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. |

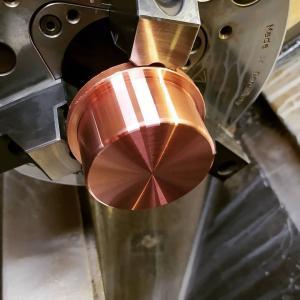

| Copper | C11000,C12000,C12000 C36000 etc. |

| Aluminum | AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc. |

| Iron | A36, 45#, 1213, 12L14, 1215 etc. |

| Plastic | ABS, PC, PE, POM, Delrin, Nylon, Teflon, PP,PEI, Peek etc. |

Surface Finishing

| Aluminum parts | Stainless Steel parts | Steel | Plastic |

| Clear Anodized | Polishing | Zinc plating | Painting |

| Color Anodized | Passivating | Oxide black | Chrome plating |

| Sandblast Anodized | Sandblasting | Nickel plating | polishing |

| Chemical Film | Laser engraving | Chrome plating | Sandblast |

| Brushing | Carburized | Laser engraving | |

| Polishing | Heat treatment | ||

| Chroming | Powder Coated |

CNC machining services for over 60 metals and plastics:

Aluminum 6061-T6: Often referred to as “aerospace aluminum alloy” due to its use in aircraft structures. It combines high strength, excellent workability and impressive corrosion resistance. Ideal for applying coatings and has excellent joining properties.

Aluminum 6060: A versatile alloy primarily used in complex cross-sections. It has good surface finish, corrosion resistance and weldability.

Aluminum 6063: Popular for construction applications due to its smooth surface finish and good extrudability. Provides medium strength and corrosion resistance.

Aluminum 6082: Mainly used in Europe, its structure is equivalent to 6061. It has good formability and weldability and is often used in high stress applications.

5052 Aluminum: Known for its processability and resistance to salt water corrosion. Commonly used in ship and aircraft fuel tanks.

Aluminum 7075-T6: One of the strongest aluminum alloys. Used in aircraft structures due to its high strength and light weight. It is less resistant to corrosion than some other aluminums, but can resist stress and crack growth.

Aluminum 5083: Known for its superior performance in extreme environments. It is resistant to seawater and industrial chemicals and is used in marine applications.

Aluminum 2024: Mainly used in the aerospace sector due to its high strength and fatigue resistance. However, it is more susceptible to corrosion than other aluminums.

304 Stainless Steel: A widely used stainless steel due to its corrosion resistance and ease of forming and welding.

303 Stainless Steel: A variation of 304 designed to be easier to machine. Corrosion resistance is slightly worse.

316 Stainless Steel: Higher corrosion resistance than 304, especially against chlorides. Commonly used in marine environments.

316L Stainless Steel: Similar to 316, but has lower carbon content to resist corrosion after welding.

Mild steel 1018: has good weldability and machinability. Typically used on bolts, rods and other products.

Mild Steel 1020: Relatively low in carbon content and easy to form and weld.

Mild Steel 1045: Higher carbon content than 1020, giving it greater strength and hardness.

Low carbon steel A36: Common structural steel in the United States, with good weldability and formability.

Alloy Steel 4140: Known for its strength, toughness and good machinability. Used in a variety of demanding applications.

Alloy Steel 1065: A high carbon steel known for its hardness. Commonly used in springs and high-strength steel wire.

Alloy Steel 4340: Known for its toughness and high strength. For use in aerospace and other critical applications. Grade 5 Titanium (Ti6Al4V): The most widely used titanium alloy. Combines strength, light weight and corrosion resistance.

Grade 2 Titanium: Commercially pure titanium. Provides a good balance of strength, ductility and corrosion resistance.

Copper C110: Known for its electrical conductivity. Often used in electrical applications and artwork.

Brass 360C: A popular variation of brass known for its workability. Commonly used in decorative items and hardware.

PTFE (Teflon): Known for its non-stick properties. Heat and chemical resistant.

Derlin (POM): Offers high stiffness, low friction and excellent dimensional stability. Used for precision parts.

PEEK: Known for its high temperature resistance and mechanical properties. Used in aerospace, automotive and medical applications.

HDPE: A general-purpose plastic with good impact resistance. Commonly used in containers and pipes.

HDPE: A general-purpose plastic with good impact resistance. Commonly used in containers and pipes.

PVC: A widely used plastic known for its durability and chemical resistance. Commonly found in pipes and electrical insulation.

ABS: Popular in the 3D printing community, it can also be CNC machined. Known for its strength, toughness and heat resistance.

Polypropylene (PP): Has good chemical resistance and is often used in packaging.

Polycarbonate (PC): Known for its optical clarity and impact resistance. Commonly found in eyewear and safety equipment.

Nylon 6: Provides a balance of strength and flexibility. Used in a variety of applications from automotive to consumer products.

UHMW: Known for its high wear resistance and low coefficient of friction. Commonly used in industrial machinery.

Related products

-

CNC Machining Parts

Rapid CNC Machining Prototype In China

-

CNC Machining Parts

CNC Lathe Machining Parts Services In China

-

CNC Machining Parts

Best CNC Machining Services In China

-

CNC Machining Parts

3Axis 4 Axis 5 Axis CNC Machining Parts