Low-Volume Manufacturing Service

AN-Prototype low-volume manufacturing services are performed in-house from start to finish.Fast Lead times and Tightest Tolerances.Competitive Price.

- ISO 9001:2015, ISO 13485 Certified.

- More than 160 Certified Materials

- Tolerances Up to ± 0.005mm

- 100% Quality Guaranteed.

- Global Delivery

On Demand, On Time Low-Volume Manufacturing Services

When designers, engineers, and R&D companies consider developing new products, the primary goal is prototyping and mass production as the first priority, but there is still a greater demand for low-volume manufacturing. AN-Prototype satisfies customers’ ability to obtain the exact quantity of parts they want, and is recognized as one of the leaders in providing the highest quality rapid low-volume manufacturing services.

When you need low-volume manufacturing solutions, AN-Prototype’s uncompromising quality and no minimum production limit are your trust. Contact us for a free quote and find out how we can support your project.

What is low-volume manufacturing?

Low-volume manufacturing is a specialized craft service that provides metal or plastic parts in full high-volume production quality. The number of parts varies from 1 to several thousand pieces. Low-volume manufacturing is ideal for moving your idea from the concept stage to prototyping and on to the bridge to high-volume production.

Customers may be concerned about whether low-volume manufacturing will sacrifice part quality or precision compared to full-scale production manufacturing. Rest assured that when we process small batch manufacturing orders, the same materials, same equipment and the same strict quality controls are used.

Trusted Low-Volume Manufacturer

Choose AN-Prototype As Your Rapid Prototyper

AN-Prototype, as a well-known rapid prototyping manufacturer in China, provides excellent quality, fast turnaround and cost-effective rapid prototyping services to customers all over the world. AN-Prototype is equipped with cutting-edge prototyping and manufacturing technologies, advanced industrial-grade equipment, and a team of expert engineers to bring your designs to market in just days. If you have finished prototyping and are ready for production, AN-Prototype is ready to be your partner.since its establishment, we were committed to providing customers with high-quality, fast turn, and affordable prototypes.

24/7 Engineering Support

A team of experienced experts is always available to provide professional advice on your orders, improvements and preferences.

Competitive Pricing

We have established an efficient and economical rapid prototyping system, which enables us to offer more competitive prices compared to any other offer.

Fast Delivery Time

Our state-of-the-art in-house production facilities and workforce help us meet and exceed your lead time expectations. We ensure that all custom parts deliveries are on schedule.

Strong Manufacturing Capability

For rapid prototyping needs, our extensive manufacturing capabilities include CNC machining, injection molding, vacuum casting, 3D printing and other services, our goal is to best manufacture custom parts that exceed your expectations.

100% Full Size Inspection Report

Invest more than 500,000 US dollars in advanced inspection equipment, extensive incoming material verification. Our reputation is based on our ability to provide the best quality assurance services in the industry.

Continuous Improvement

Ongoing investment in equipment and machinist training, using high quality certified materials and maintaining a high level of process stability enhances our ability to manufacture custom parts quickly and shortens lead times.

Low-Volume Manufacturing Capabilities

Ideal option for rapid prototyping of metal and plastic custom parts, CNC machining. CNC machining can create prototype parts with complex structures and precise details within 1-5 days.

- Linear dimension: +/- 0.025 mm (+/- 0.001 inch)

- Hole diameters (not reamed): +/- 0.025 mm (+/- 0.001 inch)

- Shaft diameters: +/- 0.025 mm (+/- 0.001 inch)

- Part size limit: 950 * 550 * 480 mm

Vacuum casting is one of the main ways to manufacture plastic parts, especially elastic plastic parts. AN-Prototype’s vacuum casting process gives you high quality, consistent plastic parts with intricate and impressive details.

- Maximum build size: 1900 x 900 x 750 mm

- Dimensional accuracy: ±0.05 mm

- Standard lead time: Up to 20 parts in 10 days or less

- Layer thickness: 1.5mm - 2.5mm

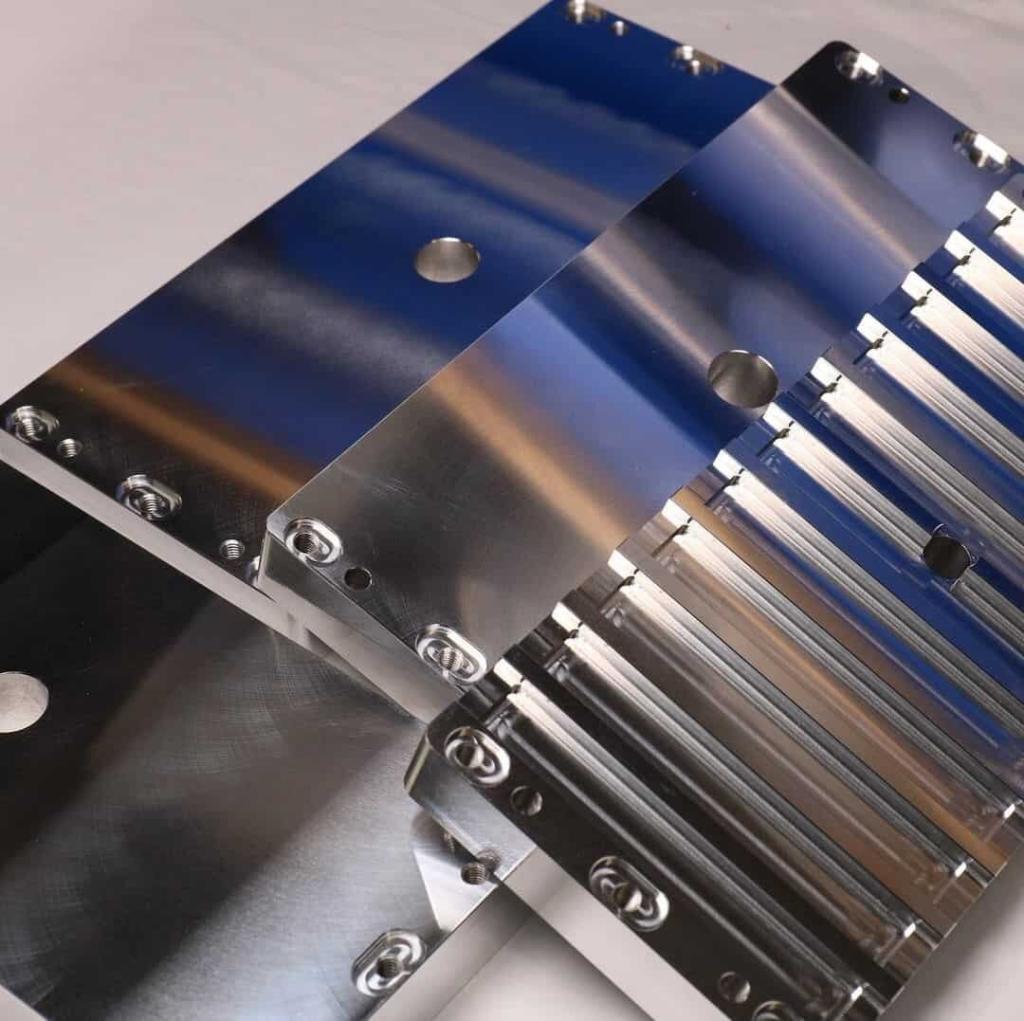

AN-Prototype sheet metal processing to produce metal parts is a combination of in-house advanced equipment production and advanced technology, ensuring short delivery times and strict quality standards.

- Edge to edge, single surface / Edge to hole, single surface / Hole to hole, single surface: +/- 0.005 inch

- Bend to edge / hole, single surface: +/- 0.010 inch

- Edge to feature, multiple surface / Over formed part, multiple surface: +/- 0.030 inch

- Bend angle: +/- 1°

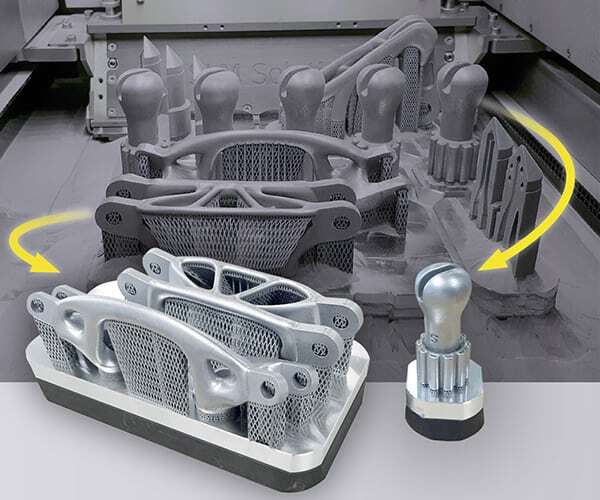

AN-Prototype utilizes advanced 3D printing technology to meet your needs for fast 3D printing services, such as SLA, SLS, FDM, etc. With our fast production capabilities and streamlined process, you are guaranteed to get custom metal or plastic parts within days.

- Min. wall thickness: 1.0 mm

- Layer height: 50 – 300 μm

- Max. build size: 250 * 250 * 250 mm (SLA)

- Max. build size: 420 * 500 * 420 mm (SLS)

- Max. build size:500 * 500 * 500 mm (FDM)

- Tolerance: ± 0.2 mm

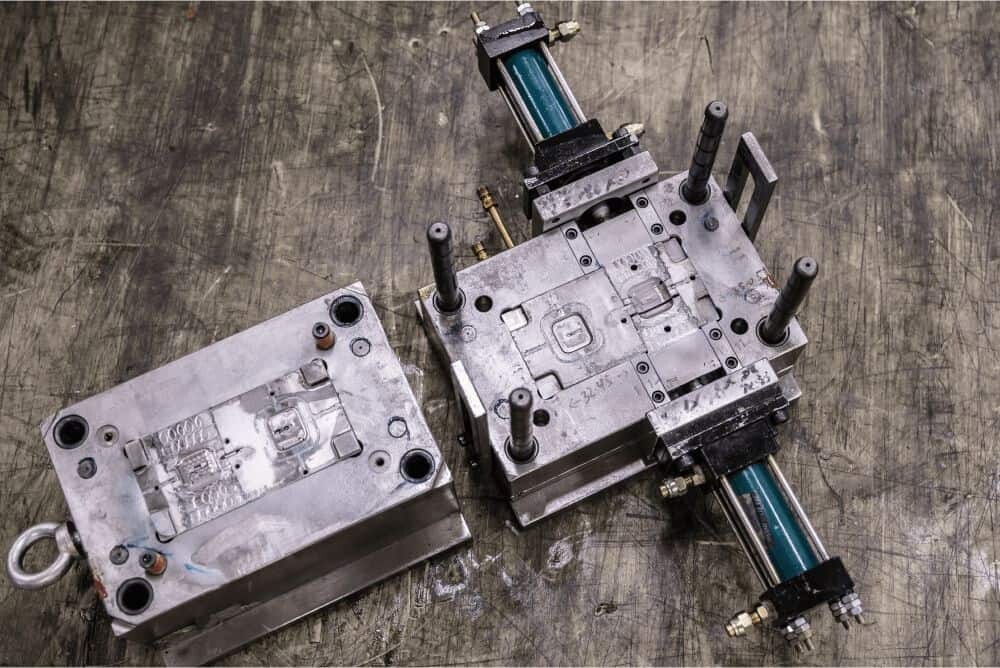

Our proven rapid tooling process is ideal for low-volume manufacturing and fabrication of plastic parts. We also apply secondary operations such as overmolding and insert molding.

- Mold cavity tolerances: ±0.05 mm

- Standard lead time: 15 business days or less

- Part to part repeatability: ±0.1 mm

- Production grade: 1-100,000 cycles

Material Options for Low Volume Manufacturing

AN-Prototype offers more than 160 metal and plastic certified materials to meet your prototyping needs for many types. You can also look at different materials and their processing costs.

Metal

There are many types of metals, and different metals have different physical and chemical properties. Differences in the properties of metals make some metals better suited to certain environments than others. Rapid prototyping processes for making metal prototypes are: CNC machining, 3D printing, and sheet metal fabrication.

- Aluminum

- Stainless Steel

- Tool Steel

- Alloy Steel

- Brass

- Copper

- Titanium

- Mild Steel

- Invar

- Inconel

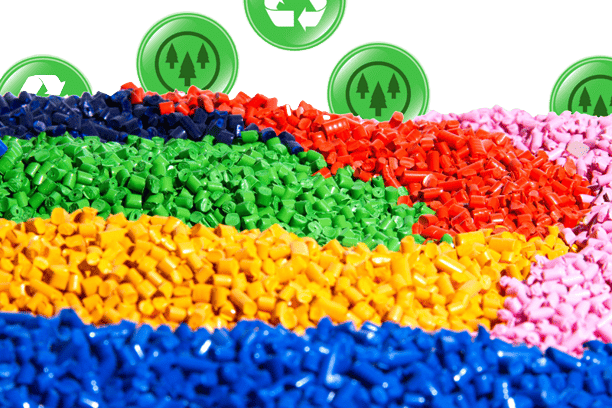

Plastics

In order to meet your different prototype functional needs, AN-Prototype reserves dozens of thermosetting plastics and thermoplastics, all of which have passed SGS inspection. We will provide you with high-quality plastic products of various materials through plastic injection molding, CNC machining, 3D printing, vacuum casting, etc. Plastic materials include but are not limited to:

- ABS

- Polypropylene

- POM

- Acaylic

- PEEK

- Polycarbonate

- Nylon

- Polyethylene

- PVC

- PET

- PTFE

- PA+GF30

- HDPE

- PEI(Ultem)

- PMMA

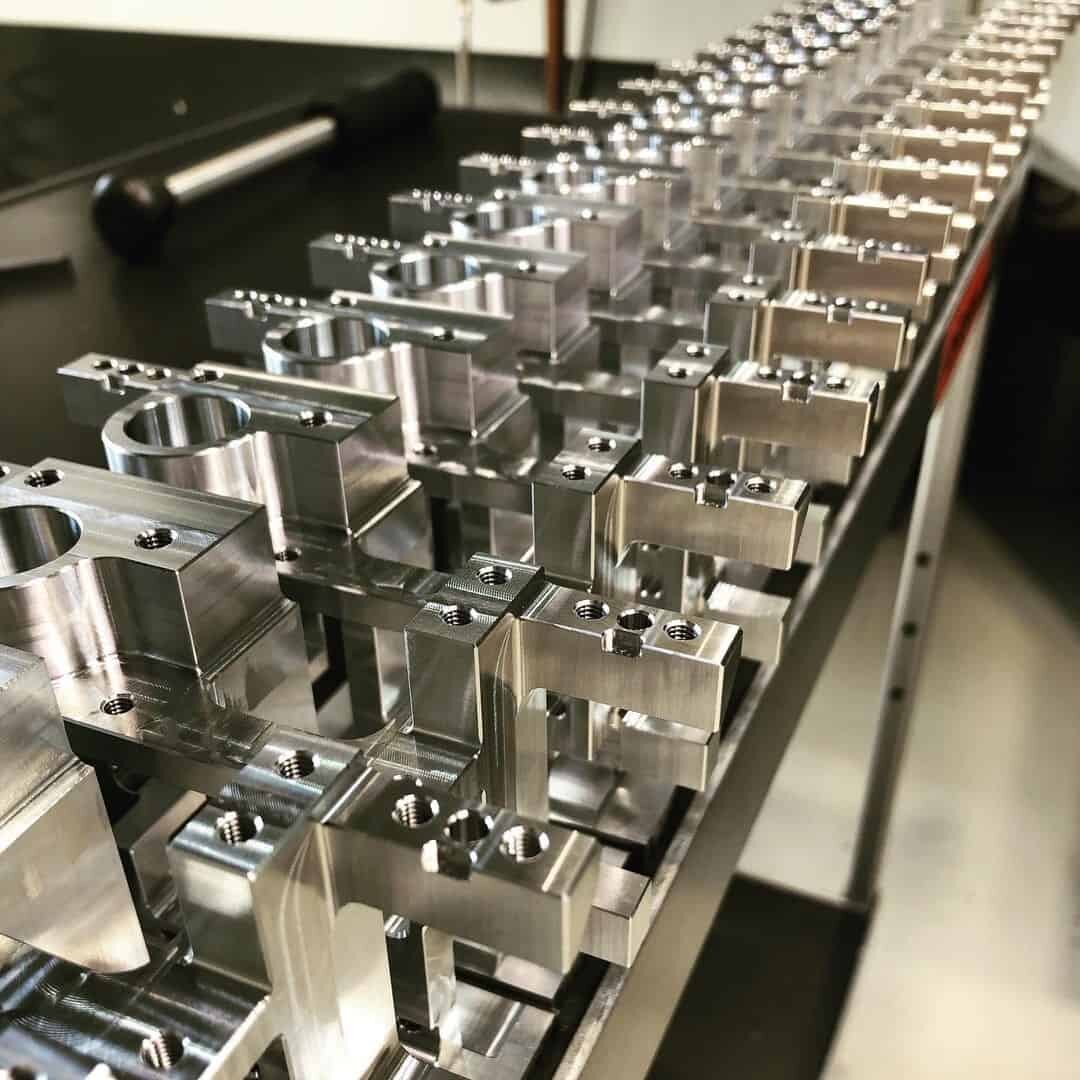

Gallery of Low Manufacturing Parts

Since 2009, AN-Prototype has manufactured hundreds of thousands of custom prototypes for various industries including medical, automotive, aerospace, construction and others.

Our Happy Clients!