Energy Prototyping

AN-Prototype supports prototyping and low-volume manufacturing in the renewable energy sector – including electric vehicles, plug-in hybrid vehicles, fuel cells and wind turbines.

- ISO 9001:2015, ISO 13485 Certified.

- More than 160 Certified Materials

- Tolerances Up to ± 0.005mm

- 100% Quality Guaranteed.

- Global Delivery

Custom Manufacturing Prototypes for Energy Industry

AN-Prototype relies on advanced processing capabilities to manufacture high-quality precision new energy prototypes. The energy industry spans hydrocarbons and renewables, and the manufacture of components is a critical step in the supply chain to ensure the efficient operation of any energy asset in the oil and gas, renewables or nuclear sectors. From prototyping to series production, we manufacture safer, more reliable, more sustainable and more efficient energy components, from components for wind turbines and solar panels to valves and pipelines for the oil and gas industry.

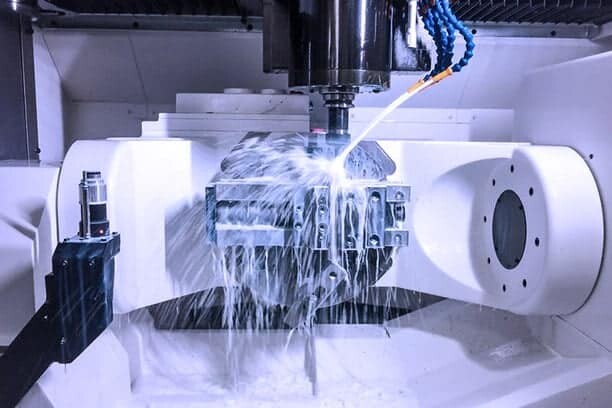

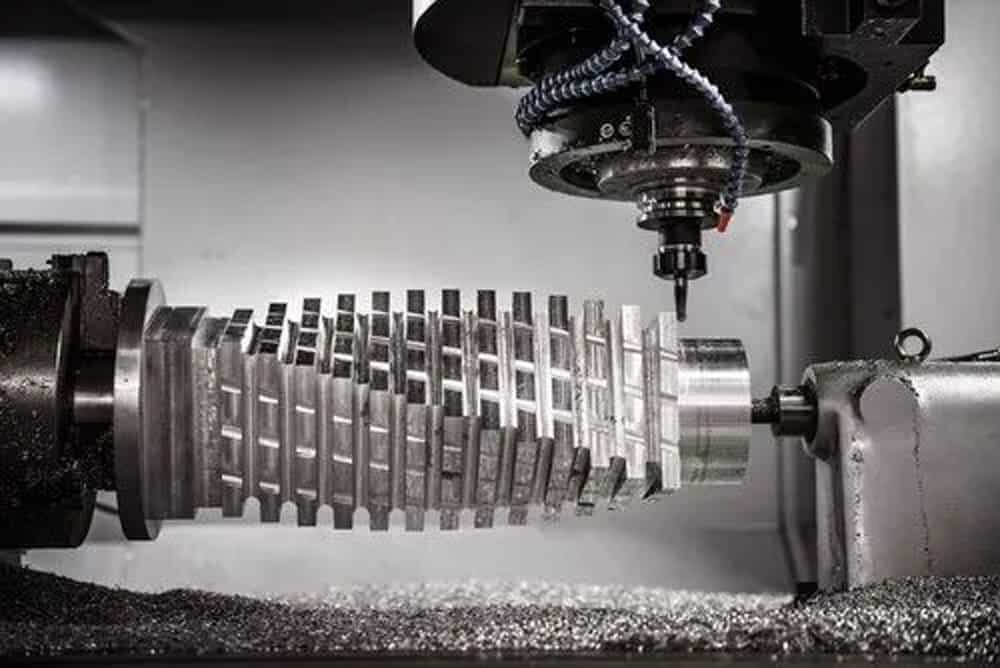

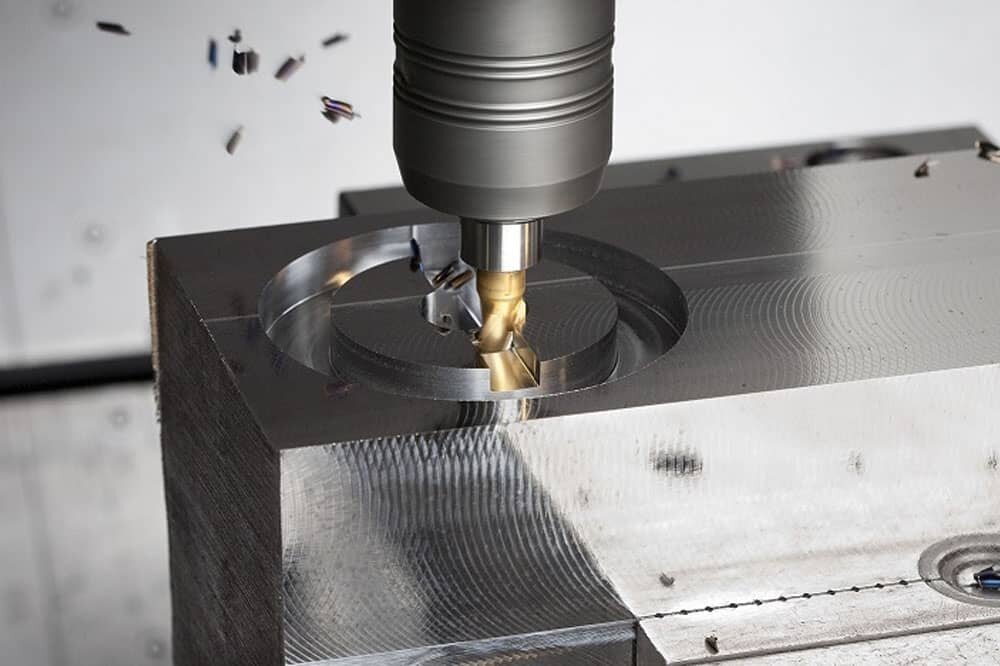

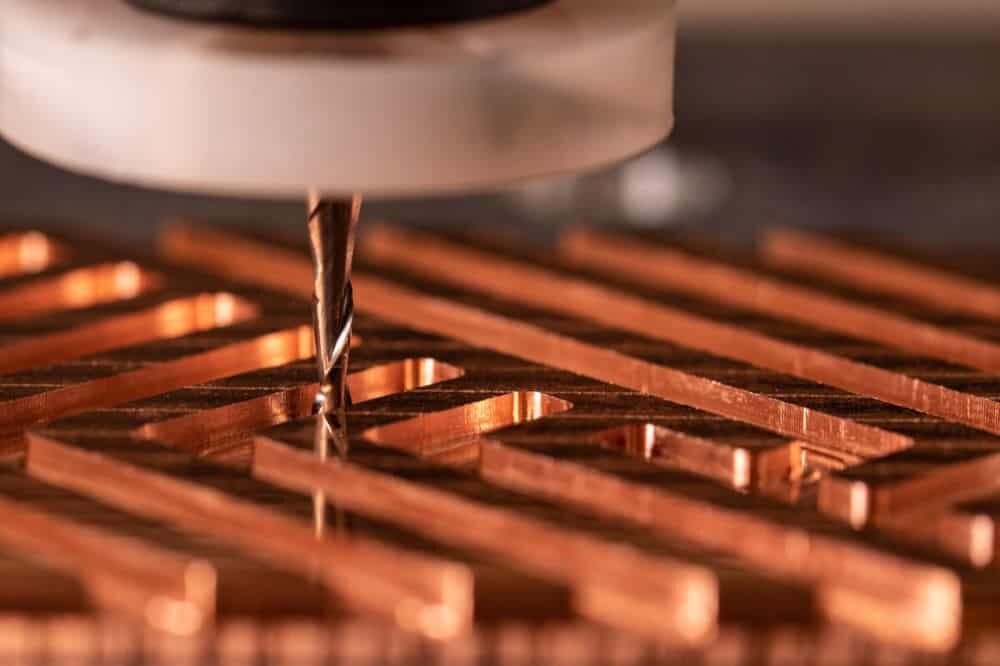

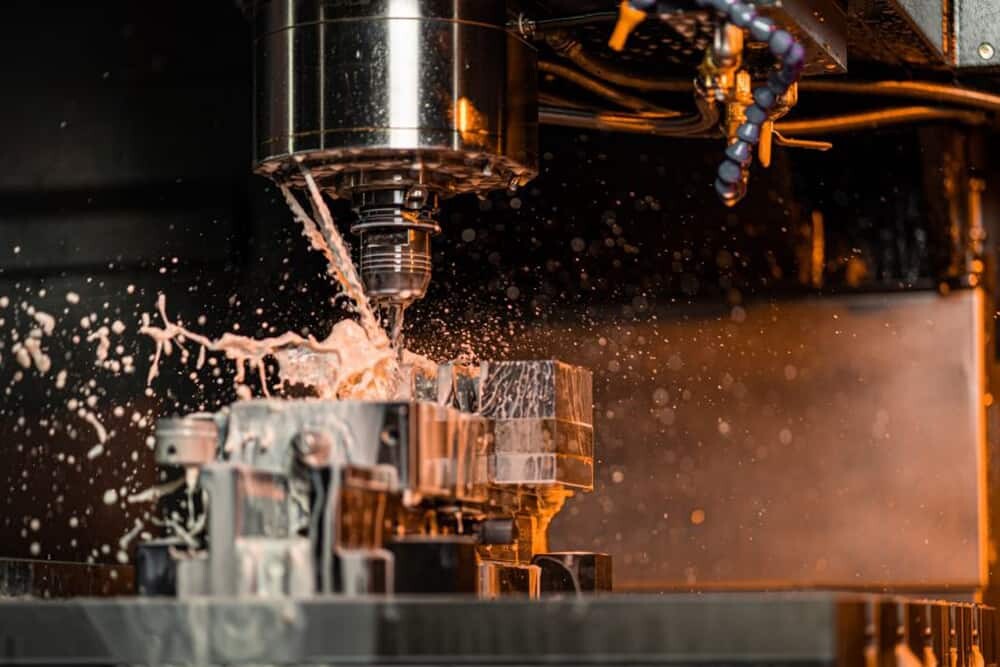

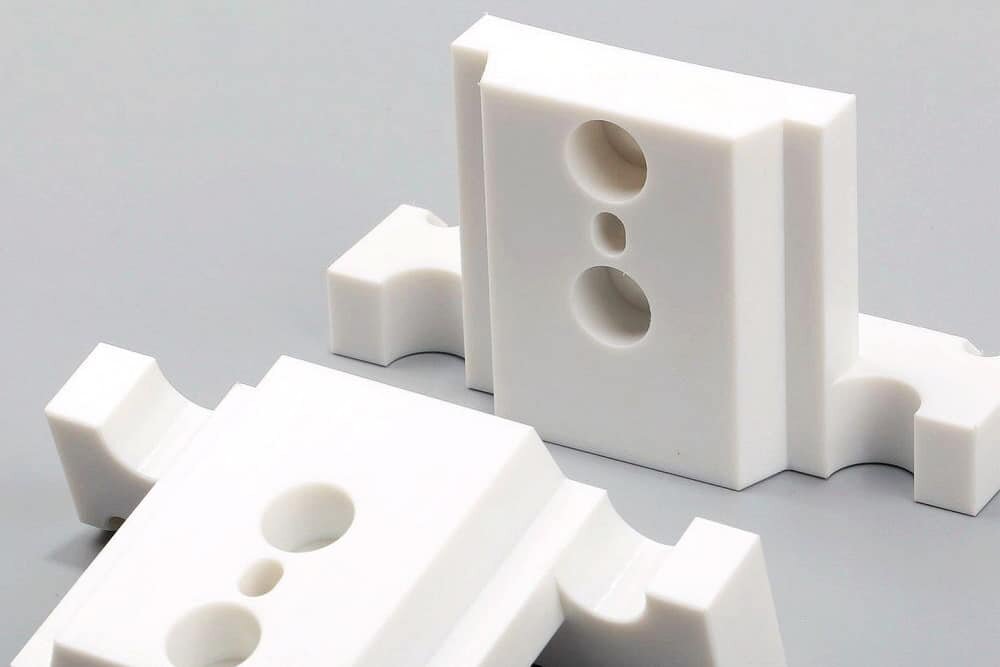

CNC Machining Energy Prototype

CNC machining plays an important role in the manufacture of metal or plastic parts in the energy industry, enabling the rapid and efficient manufacture of complex, precise, high surface finish, high tolerance parts.

3D Printing Energy Prototype

3D Printing - Additive Manufacturing enables high quality energy prototypes and final components while maintaining relatively low costs and fast turnaround times, reducing labor-intensive processes and reducing costs.

Rapid Tooling Energy Prototype

Rapid tooling is the ideal solution for manufacturing small batches of plastic parts. Some of the more common molded plastics in the energy industry include: PEEK, LSR and Tecaform for housings, seals, gears and more.

Trusted Rapid Prototyping Manufacturer

Energy Prototyping Experts Ensure Quality

As an ISO 9001:2015 certified rapid prototyping company, AN-Prototype strictly enforces ISO standards throughout its production line to deliver consistently high quality custom energy prototypes. Our rapid prototyping and production lines also employ cutting-edge technology to ensure precision and precision in manufacturing. With advanced in-house test and measurement tools, we ensure that each energy component meets your required specifications.

Expert Technical Support

AN-Prototype engineers and technicians are dedicated and can provide you with proactive and professional support (24/7) to help solve your problems.

- One-to-one technical support

- Professional and rich experience

- Elite Engineers and Technicians

Strict Quality Control

We follow strict quality control system ISO9001&ISO13485, internal advanced testing instrument CMM to ensure the manufacture of high-quality prototypes.

- ISO 9001 and 13485 certified

- Strict Manufacturing Standards

- Advanced Manufacturing Facility

Rework and Refund Policy

If the prototype does not meet the required specifications, please contact us within five working days of receiving your order and we will resolve your issue within 1-3 working days.

- 30-day warranty

- Responsive replies and support

- Genuine after-sales policy

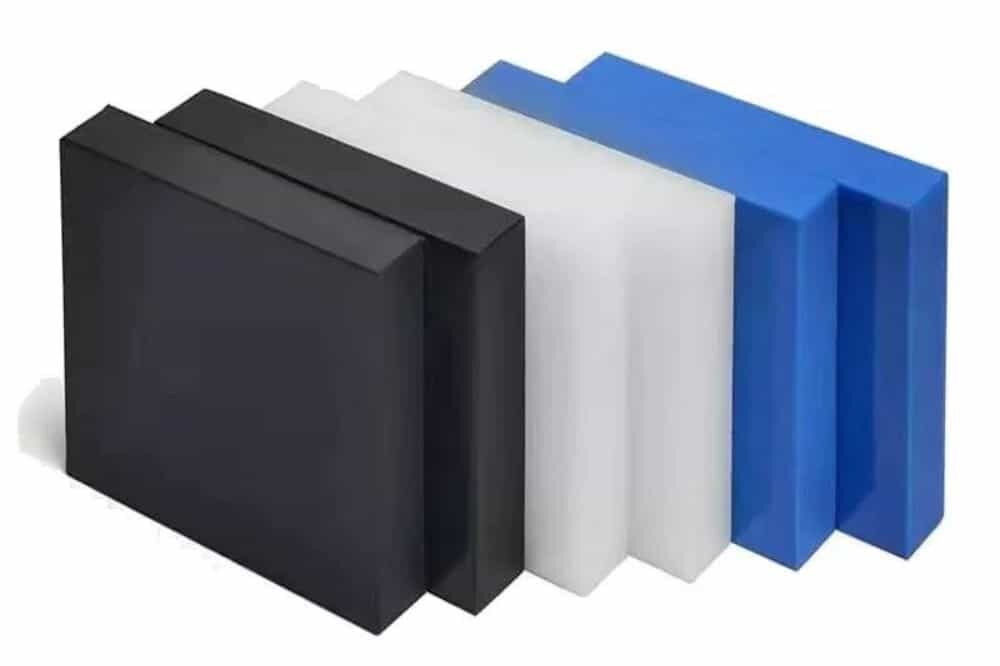

Materials for the Energy Industry

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Aluminum

Aluminum is highly machinable and less expensive than carbon steel, tool steel, and stainless steel, making it ideal for CNC machining. Rapid Manufacturing companies can process aluminum three to four times faster than other commonly processed materials such as steel and titanium. Aluminum is non-toxic, “lightweight” that can easily replace heavier metals, and is corrosion resistant, readily available and infinitely adaptable material. Common aluminum materials are AL6061\AL7075\AL5083\AL6082.

Stainless Steel

With excellent machinability and excellent uniformity, stainless steel is a very common CNC machining project material. Stainless steel also offers good weldability, high ductility, formability, corrosion resistance, wear resistance, and tensile strength to meet the needs of your specific project. Common stainless steel materials are SU304\SU316, SU303\17-4PH\420. Stainless steel is used in medical equipment Machine parts, food industry, gears, heavy construction equipment, vacuum and pressure vessels, etc.

Magnesium Alloy

Magnesium is a lightweight metal whose main appeal is its weight, as light as plastic but as tough as metal. When alloyed, magnesium’s strength-to-weight ratio exceeds that of all other structural metals. This gives the material a tensile strength comparable to steel and aluminum. Magnesium has a high level of machinability and can be CNC machined to create parts with high strength and excellent corrosion resistance. CNC machining magnesium is a dangerous business as it can easily catch fire or explode. Magnesium is the lightest structural metal and also provides an excellent surface finish when machined.

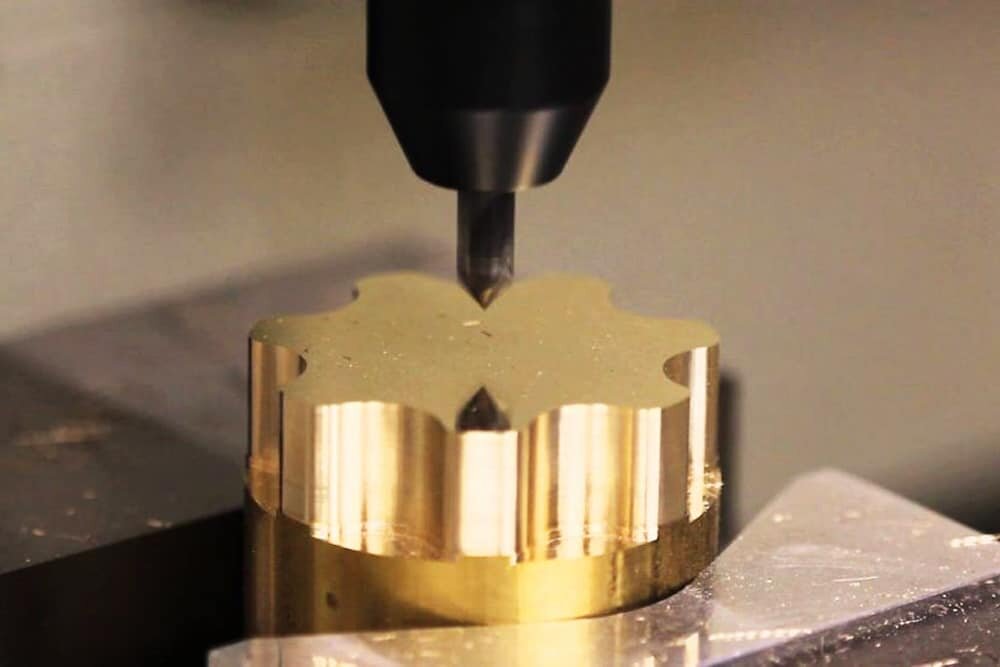

Brass

Brass contains copper, zinc and other metals such as magnesium, iron and lead. These alloying metals all contribute to its properties, and the addition of lead makes it very easy to CNC machine. Brass is highly machinable, corrosion-resistant, and ductile. The common models are C360\C220\C230, which are used in hinges, knobs, plumbing equipment, bells, jewelry, gears, door decorations, etc.

Copper

Most CNC copper parts have good machinability, ductility and impact strength. They also have high thermal conductivity, electrical conductivity, corrosion resistance and wear resistance. CNC copper parts are compatible with a variety of cost-effective surface treatments, including milling, grooving, drilling, tapping, spot facing, chamfering, threading, knurling, brazing, grooving, trimming, and nickel plating.

Zinc Alloy

Zinc alloy metal is one of the cheapest metal materials. Although less expensive, they have good mechanical strength, are easy to CNC machine, and resist mechanical shocks well. Complex components are often die cast first and then CNC machined to create critical features, reducing overall CNC machining time and cost. CNC machined zinc alloy parts are widely used in the automotive industry.

Titanium

Titanium has an excellent strength-to-weight ratio and corrosion resistance, and is also relatively easy to machine and weldable. It is also beneficial for almost all surface finishing processes including: sandblasting, powder coating and electrophoresis all give good results when applied on titanium. Despite its high price, titanium is still a very popular material. Titanium’s high strength, corrosion resistance, good strength-to-weight ratio, ductility, good machinability, and a variety of surface treatment options are often used in industries such as aerospace, automotive, and medical. Titanium aerospace CNC machining includes aircraft engine parts, fuselage parts, rotors, compressor blades, etc. Two-thirds of the total titanium produced in the world is used in aircraft engines and airframes. In the medical field, titanium parts include surgical implants (such as long-term hip replacements) and instruments. The metal is also used to make items such as wheelchairs and crutches.

Bronze

Bronze is made of copper mixed with up to about 35% tin and up to 8% lead. It is easy to machine because it contains lead alloy (a soft metal). Bronze is well suited for applications such as bearings and marine applications requiring pumps and fittings resistant to seawater corrosion. The mechanical properties of this material cannot be compared to many other machinable metals, making it best suited for low stress components manufactured by CNC machining. Bronze, brass and other copper alloys have a range of important electrical, mechanical and corrosion resistance properties. Specifically, bronze has excellent machinability with an index of 100%. It also has low-friction properties, making it ideal for parts subject to continuous frictional contact. Common bronze models are 932, 954, 544.

Inconel

Inconel, a superalloy with a high nickel content and excellent corrosion and oxidation resistance, is known to be very difficult to machine. Inconel® is an ideal material option for high temperature applications, suitable for extreme environments. Inconel® is an expensive metal used in aerospace, defense, military and more. AN-Prototype's CNC machining of two types of Inconel: Inconel® 625 and Inconel® 718. AN-Prototype has the capability to manufacture Inconel® parts, such as internal engine components that require tight tolerances and threaded features, with extremely fine surface finishes. AN-Prototype aligns manufacturing processes to maximize efficiency and manufacture quality Inconel parts in-house for customers.

ABS

ABS is a common thermoplastic that is a low-cost solution for CNC-machined, injection-molded parts. ABS has good mechanical properties, very high impact strength, good heat resistance and is easy to process. Applications include prototyping, enclosures and protective components.

PA(Nylon)

Nylon is an engineering thermoplastic material with good comprehensive mechanical properties, impact resistance, excellent abrasion resistance and chemical resistance, but it is easy to absorb moisture. Nylon is stronger and can withstand higher temperature environments than PTFE and PEEK. Typical applications include bushings, bearings, gears, insulators, and aerospace and medical parts.

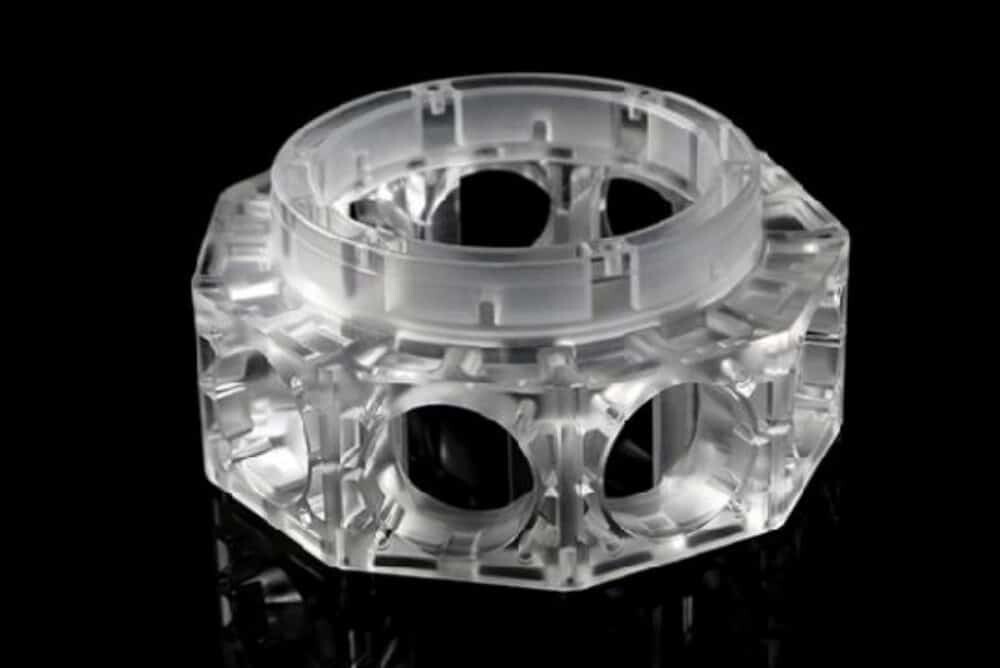

PC

PC is one of the most commonly used plastics in manufacturing and is used in various types of applications. PC has the characteristics of heat resistance, flame retardancy, impact resistance and recyclability. Its applications are not limited to automotive lighting systems, aerospace glass replacement parts, laboratory lenses, heat-loaded plastic parts, and other electrical applications.

ABS+PC

Polycarbonate/Acrylonitrile Butadiene Styrene (PC-ABS) is an engineering thermoplastic blended from PC and ABS. This material combines the best of PC and ABS, and its unique properties depend on the ratio of PC to ABS in the blend, the molecular weight of the polycarbonate, and any thermoplastic additives in the blend.

PMMA(Acrylic)

Also known as acrylic or plexiglass, PMMA is a common clear thermoplastic that is often used as a replacement for lightweight and shatter-resistant glass parts. PMMA is considered more cost-effective than PC when clarity and UV resistance are more important than impact strength. Typical applications include lenses and sensors, medical implants, smartphone screens and automotive windows, automotive taillights, headlights and light guides.

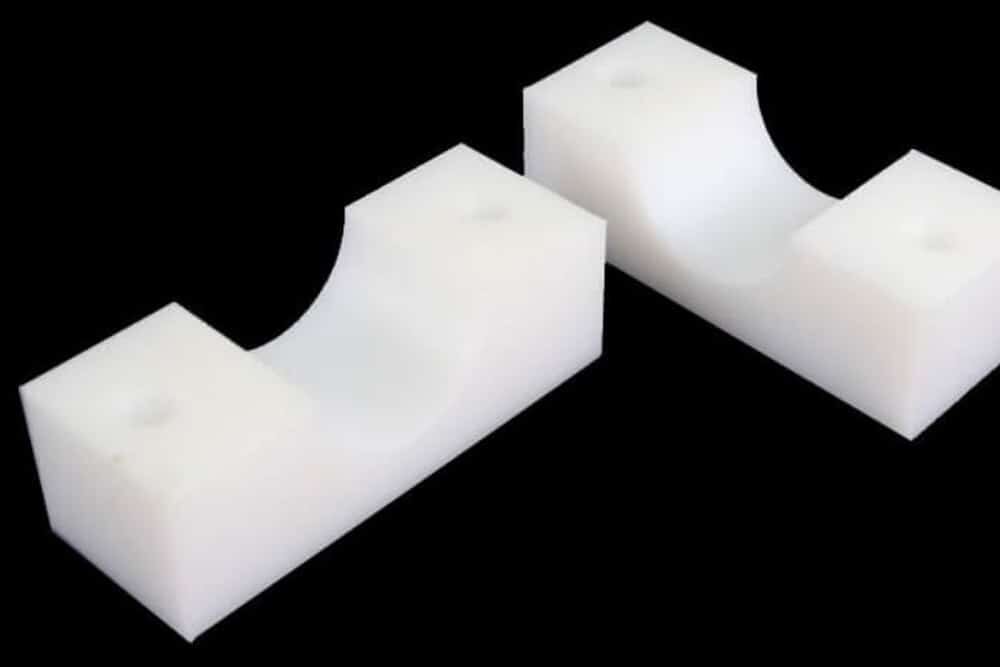

POM(Acetal / Delrin)

POM, also known as Delrin or polyoxymethylene in the industry, is a low-friction engineering plastic with impact and high temperature resistance, high stiffness, and excellent dimensional stability. When CNC machined, POM combines high strength and elasticity. Unlike nylon, it has very low moisture absorption; ideal for machining precision mechanical parts. . Typical applications include bearings, gears, insulators, and pump components, plumbing components, home appliances, automotive components, consumer electronics, and more.

PEEK

PEEK, also known as polyether ether ketone, is a common high-strength plastic that often replaces soft metal parts that require high strength and stiffness. PEEK also has very high resistance to heat, chemicals and moisture. PEEK is one of the few plastics compatible with high vacuum environments, and these properties make it ideal for aerospace, automotive, medical, semiconductor and chemical applications.

PTFE

Teflon (PTFE) is an extremely elastic engineering thermoplastic with the lowest coefficient of friction of any solid material. It has very low moisture absorption compared to nylon and is therefore also suitable for applications in wet conditions. PTFE has excellent chemical and heat resistance, making it ideal for manufacturing parts used in chemically harsh environments, ideal for moving parts that require high strength, low friction, and long-term durability.

PAGF30

PAGF30 is a glass fiber reinforced plastic with increased strength, stiffness, creep strength and dimensional stability as well as heat resistance. These properties of PA GF30 make the material suitable for parts subjected to high static loads for long periods of time at high temperatures. Glass filled nylon 6 is less suitable for sliding applications as glass fibers tend to have a noticeable abrasive effect on mating surfaces in some cases.

PP

Polypropylene (PP) is an inexpensive thermoplastic whose impact resistance varies with grade. Abrasive, flexible, and capable of high elongation, PP also has high chemical resistance, making it ideal for flexible and lightweight CNC machined parts.

HDPE

HDPE is a thermoplastic made from a string of ethylene molecules (hence, the poly part of polyethylene) known for being lightweight and strong. HDPE has excellent impact resistance, high strength and good machinability, and is suitable for strong and durable machine parts.

PE

Polyethylene (PE) is a thermoplastic with excellent impact resistance, high ductility and low friction, making it ideal for machining wear-resistant parts. PE is mainly used for blow molding and has high temperature resistance, oil resistance, steam permeability resistance and environmental stress cracking resistance. PE also has good electrical insulation, impact resistance and temperature resistance.

PET

PET is a tough, dimensionally stable plastic with excellent abrasion resistance and mechanical strength. PET is very machinable, so there are few restrictions to consider when machining. It is recommended to use sharp cutting tools to avoid chipping during machining.

PVC

PVC is a high-strength thermoplastic material with excellent chemical resistance, good mechanical strength and ease of processing; suitable for strong and chemically resistant components. It is widely used in pipelines, medical equipment, wire and cable insulation and other fields.

Ceramics

CNC milling, drilling, turning and other processing methods can be applied to ceramic parts in the pre-sintered state. In terms of cutting tools, titanium nitride (TiN) coated high-speed steel cutting tools, tungsten carbide cutting tools and polycrystalline diamond (PCD) cutting tools are used for the processing of pre-sintered ceramics.